Hysitron TS 75 TriboScope

Hysitron TS 75 TriboScope

The Hysitron TS 75 TriboScope delivers quantitative, rigid-probe nanoindentation and nanotribological characterization capabilities to Bruker's world-leading atomic force microscopes. The Hysitron TriboScope interfaces with select Dimension and MultiMode AFMs to expand the characterization capabilities of these microscopes. By utilizing a rigid test probe, the TriboScope removes the intrinsic limitations, variability, and complexity associated with cantilever-based measurements to deliver quantitative and repeatable mechanical and tribological characterization over nanometer-to-micrometer length scales.

The Rigid-Probe Advantage

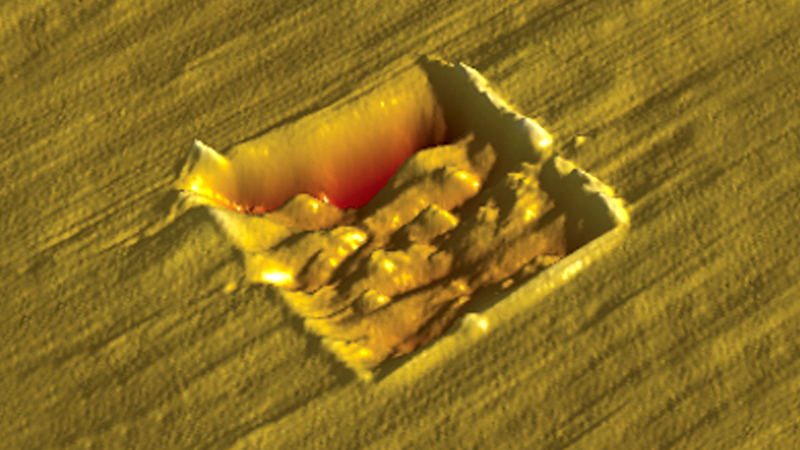

Most AFMs utilize a compliant cantilever to conduct mechanical or tribological testing, posing significant challenges in separating a cantilever’s flexural and rotational stiffness from the material’s response to applied stress. The TriboScope utilizes a rigid test probe assembly, allowing direct control and measurement of applied force and displacement during the test.

Proprietary Electrostatic Force Actuation

The TriboScope utilizes proprietary electrostatic force actuation and capacitive displacement sensing transducer technology to deliver industry-leading noise floors and low thermal drift for characterizing properties to the bottom of the nanoscale.

Force and Displacement Feedback Control

The TriboScope operates under closed-loop force control or displacement control. Utilizing a 78 kHz feedback loop rate, the TriboScope can respond to fast material deformation transient events and faithfully reproduce the test function defined by the operator.

Expand Hysitron BioSoft's Capabilities

LEARN MORE:

Contact us for more information about available upgrade options and how Hysitron BioSoft can be configured to meet your specific measurement needs now and grow with your research going forward.