M&M 2025

Enhance Your Microscopy Research with Bruker

Discover Bruker’s powerful portfolio of microscopy and spectroscopy solutions and connect with our experts to learn how our technologies are advancing research in materials science, semiconductors, polymers, and life sciences.

- Be one of the first to see eWARP, the fastest and most sensitive EBSD detector ever, in action. Find out firsthand how this revolutionary detector is changing the microanalysis landscape, facilitating EBSD like never before.

- Learn how the new Dimension Nexus benchtop AFM integrates milestone Bruker innovations into a cost-effective system to deliver wider access to top AFM performance.

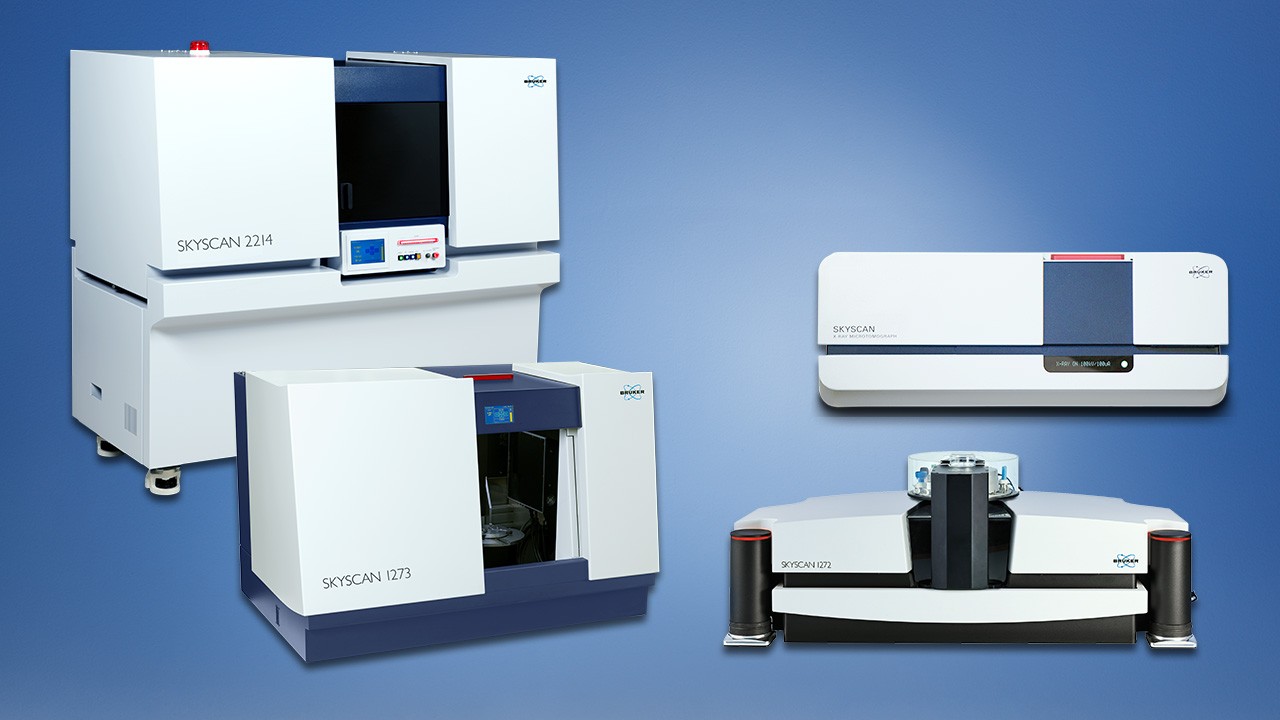

- Discover our portfolio of 3D X-Ray Microscopy (XRM) solutions based on micro-CT technology, featuring the new X4 POSEIDON benchtop 3D-XRM system.

- Discover our range of solutions to enhance electron microscopy with the power to perform elemental and microstructural analysis using techniques such as EDS, WDS and micro-XRF on SEM.

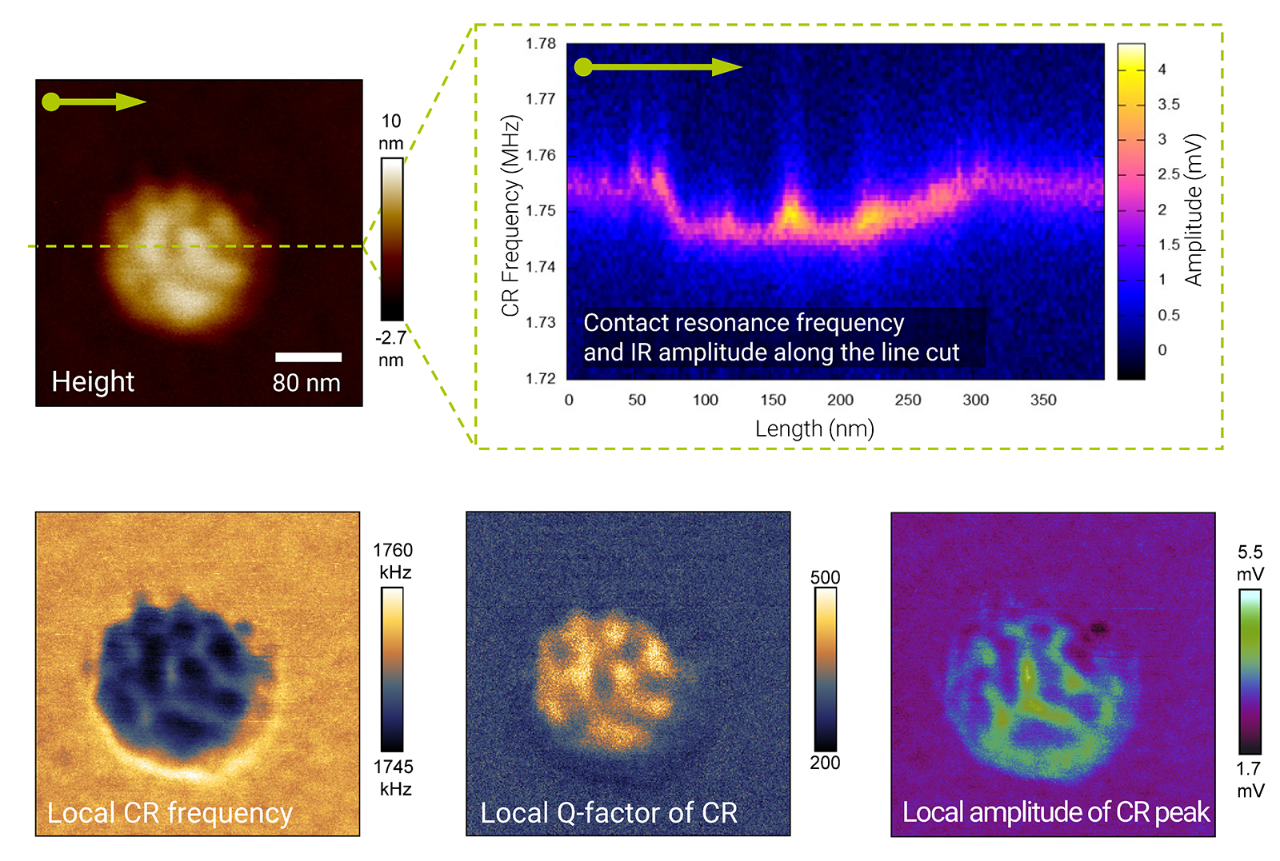

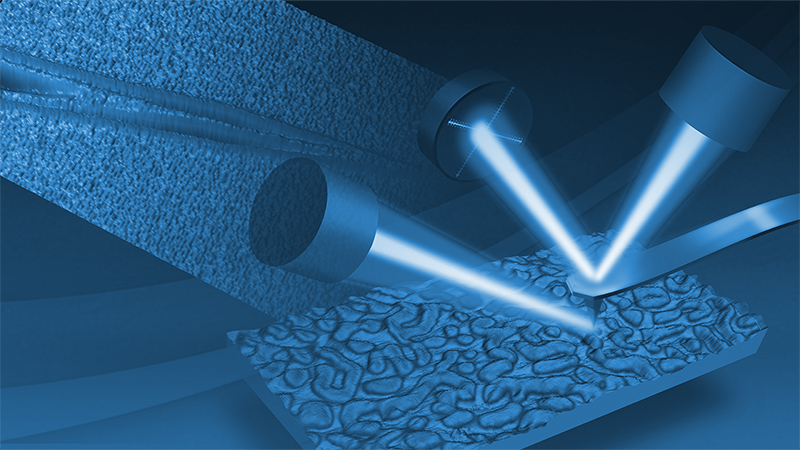

- Explore the power of nanoIR spectroscopy, including the new REFV AFM-IR mode for extended sample compatibility and measurement capabilities.

- See how our Scanning Transmission Electron Microscope, Nion, enables electron microscopy at the atomic scale.

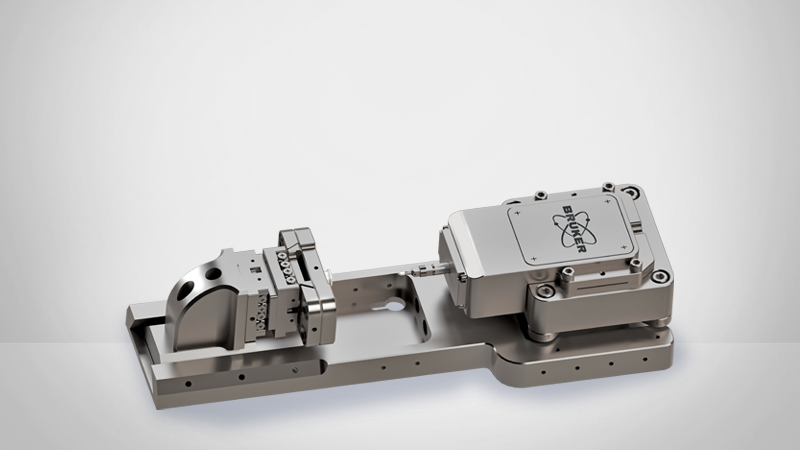

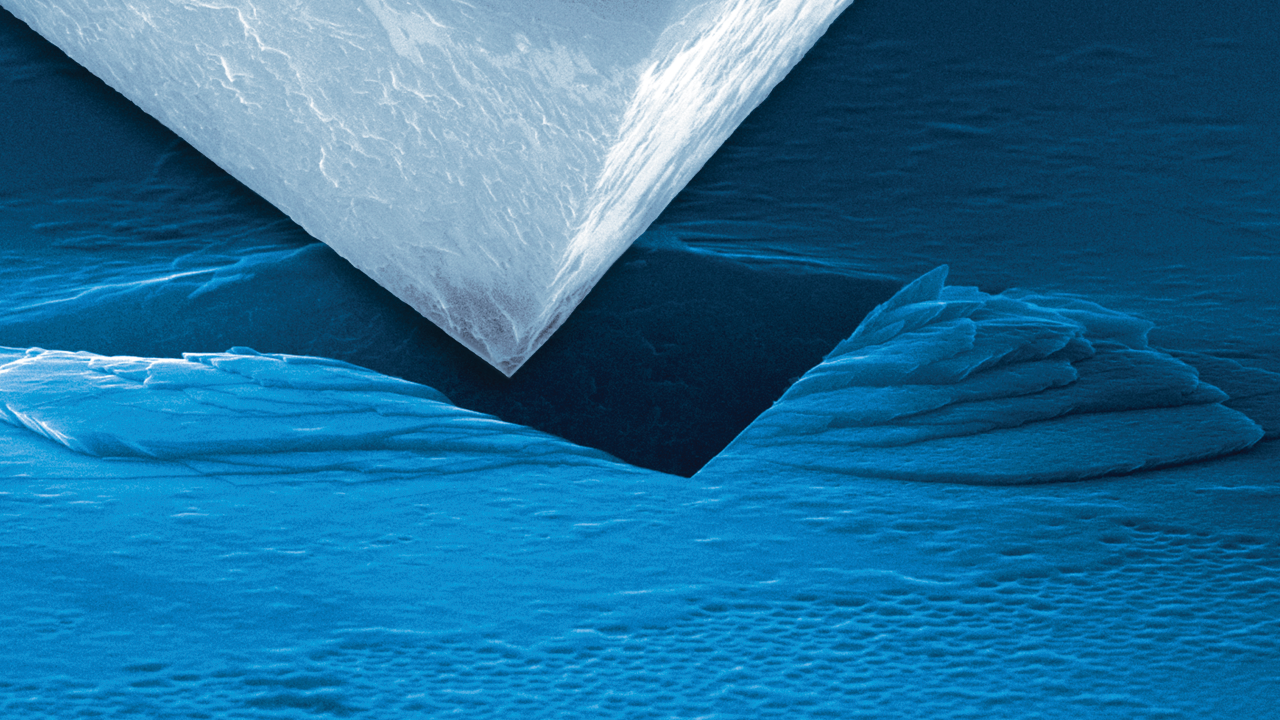

- Experience the advanced capabilities of our PicoIndenters for in-situ nanomechanical testing and precise, high-throughput materials characterization.

If you are interested in learning more about these technologies and how they can enhance your research then visit us at Booth 1424 or book a meeting with us at M&M.

Live Demos at the Bruker Booth

eWARP: The Fastest & Most-Sensitive EBSD Detector Ever

Bruker is proud to showase our revolutionary eWARP EBSD detector that delivers unmatched speed and performance. Powered by a novel direct electron detector, eWARP dramatically outpaces traditional EBSD systems, delivering faster acquisition rates without compromising data quality. Unlike other solutions, eWARP's detector was engineered from the ground up by Bruker, purpose-built to optimize EBSD analysis.

Be among the first to experience the future of EBSD by booking a live demo at the Bruker Booth, number 1424.

If you are not able to attend the conference we will also offer live online demos once the conference has ended. Just select the "online" option in the form.

Nion: Scanning Transmission Electron Microscopy at Atomic Resolution

No registration is required for demos on our Nion STEM for atomic scale imaging. Just turn up at the Bruker Booth, number 1424, at 4:00pm on Tuesday or Wednesday.

Atomic Resolution Imaging Below 10 Kelvin

Tuesday July 29

The liquid helium cryo-stage is available for the Bruker Nion series of aberration-corrected STEM instruments. Our new cryo-stage allows for STEM-EELS and 4D-STEM with atomic resolution, all at sample temperatures below 10 Kelvin with continuous operation times of up to 20 hours. The sample temperature can be set up to 80 Kelvin with exceptional temperature and mechanical stability. The latest capabilities of the cryo-stage will be demonstrated.

Atomic Resolution Secondary Electron Imaging

Wednesday July 30

Bruker's Nion Scanning Transmission Electron Microscopes now feature secondary electron detectors on both the top and bottom sides of the sample. Combined with its aberration corrector, a near UHV (1e-10 torr) pressure in the sample stage, and an in-situ laser based surface cleaning capability, the microscope readily achieves atomic resolution secondary electron imaging, simultaneous with the existing imaging channels. In this live demonstration, we will showcase these capabilities by imaging the surfaces of various materials at atomic resolution.

Lunch & Learns at M&M 2025

We’re hosting Lunch & Learns right in our booth, where Bruker scientists present key applications and technologies whilst you enjoy a complementary lunch. Space is limited so make sure to reserve your seat!

Each Lunch & Learn takes place at the Bruker Booth, number 1424, at 12:30 PM.

- Monday July 28 - EBSD 4.0 is Here and is Based on Pixelated Sensors, i.e., Direct Electron Detection!

- Tuesday July 29 - Correlation of Mechanical Properties, Microstructure, and Analytical Mapping of Materials using PI 89 Auto SEM PicoIndenter

- Wednesday July 30 - Latest Advancements with Bruker's Nion Scanning Transmission Electron Microscopes

- Thursday July 31 - Revolutionizing Benchtop 3D X-ray Microscopy: The Bruker X4 POSEIDON

Vendor Tutorials

Bruker will also be offering Vendor Tutorials after hours in the booth—no RSVP required. Just stop by our booth, grab a seat, and enjoy the insights.

All vendor tutorials will be taking place at the Bruker Booth, number 1424, at 5:45 PM.

Monday July 28 - Nanoscale Chemical Identification and Mapping with AFM-IR

AFM-IR (Atomic Force Microscopy-Infrared) is a complementary technique to SEM EDS which can provide non-destructive <10 nm lateral resolution chemical identification in ambient conditions. AFM-IR correlates strongly with traditional FTIR spectroscopy which allows FTIR chemical libraries to be used to identify compounds measured with AFM-IR. This presentation introduces AFM-IR, discusses the benefits of the technique and its core strengths in identification of lighter elements, especially carbon containing species and highlights core applications of this novel technique.

Tuesday July 29 - Benchtop XRM for Materials Science: Accessible, Modular, and Non-Destructive 3D Imaging Solutions

Benchtop X-ray Microscopy (XRM) using the X4 POSEIDON is redefining analysis by delivering high-resolution, non-destructive 3D imaging in a compact, modular format. XRM with this new system enables detailed internal visualization and quantification of metals, polymers, composites, and more — ideal for applications like additive manufacturing, failure analysis, and porosity characterization. Discover more in this tutorial.

Wednesday July 30 - Atomic Resolution Secondary Electron Imaging

Bruker's Nion Scanning Transmission Electron Microscopes now feature secondary electron detectors on both the top and bottom sides of the sample. Combined with its aberration corrector, a near UHV (1e-10 torr) pressure in the sample stage, and an in-situ laser based surface cleaning capability, the microscope readily achieves atomic resolution secondary electron imaging, simultaneous with the existing imaging channels. In this live demonstration, we will showcase these capabilities by imaging the surfaces of various materials at atomic resolution.

Poster Presentations at M&M

As part of the symposium program Bruker's experts will be presenting posters at M&M. Make sure to attend to keep up with the latest advances.

Facilitating Nanomechanical Evaluation of Heterogeneous Microstructures

- Session: A07.P2 - Advances in SEM Instrumentation, Application and Techniques

- Time & Date: Thursday July 31, 2025 | 3:00 PM - 5:00 PM

Discover Smarter Support - Bruker LabScape and Enhanced Remote Tools

Our Service team will be showcasing how Bruker is redefining service support. Stop by the booth to experience our Enhanced Remote Tools in action. These remote tools allow our experts to be virtually present in your lab, helping to diagnose issues quickly and efficiently. We’ll demonstrate how easy it is to connect with us and we’ll show how support can be even more immersive with your smartphone or an optional AR headset. Come learn how Bruker is making service smarter, faster and more accessible.

Products & Technologies Featured at M&M

eWARP: EBSD Detector with Direct Electron Detection

Enter the new era of EBSD with eWARP - our revolutionary EBSD detector that is changing the microanalysis landscape thanks to its unique direct electron detection technology.

Discover eWARP at M&M by booking a one-on-one demo at the Bruker Booth.

Dimension Nexus Benchtop AFM

Dimension Nexus™ delivers an ideal combination of data quality, experiment flexibility, and ease of use in a small-footprint system. It incorporates the milestone innovations of Bruker's NanoScope® 6 controller, PeakForce Tapping® technology, and ScanAsyst® Plus self-optimizing imaging software to deliver more functionality than competing systems in its class. Suitable for both routine and custom experiments and easily upgradable in the field, Dimension Nexus is both an excellent starter system and a perfect addition to any thriving AFM lab.

Thank you

Your request has been recieved. We will be in touch shortly and look forward to seeing you at M&M 2025.

You can email us with more information at productinfo@bruker.com.

If you would like to connect with a Bruker representative immediately, here are our regional offices:

Asia: +65 6540 4388

China: +86 10 5833 3000

Europe: +33 172 86 61 00

Japan: +81 3 3523-6361

North America: +1 805-967-1400