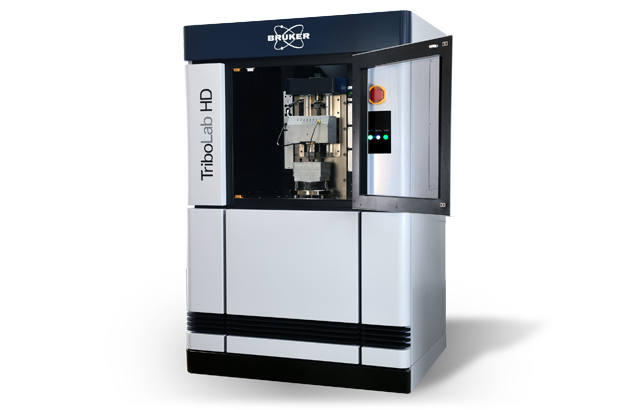

TriboLab HD

TriboLab HD

The TriboLab HD high-torque friction materials tester enables more precise and repeatable brake friction, wear, and particle emissions studies than previously possible in a laboratory setting.

This system features the most advanced technology and offers the widest range of test capabilities, the most control over test parameters and conditions, and the most force torque in a research testing system, as well as support for brake particle analysis. With the ability to simulate the SAE J2522 protocols and other standards in the lab, TriboLab HD provides the data needed to make critical decisions earlier in the brake material development process, bridging the gap between the drawing board and dynamometer testing of brake pad and rotor materials.

TriboLab HD uniquely enables engineers and manufacturers to reduce development time and comply with emerging standards and consumer demands, while reducing costs and staying ahead of their competitors.

To learn more, continue reading, contact us, or see FAQs about this product.

Bridging the Gap Between Drawing Board and Dynamometer Testing

Traditionally, dynamometer testing is the only method used to evaluate novel brake pad formulations under simulated driving conditions before actual on-road vehicle testing.

TriboLab HD provides the notable advantage of comprehensive materials testing under the various driving conditions required for regulatory compliance or certification earlier in the development cycle. This allows researchers to fine-tune materials formulations to a greater extent before expensive dynamometer testing.

Dynamometer Testing:

- Adds considerable expense if brake material formulations cannot initially meet standards;

- Occurs at a later stage in the development cycle;

- Requires test runs to be completed over several days;

- Provides little insight into the mechanisms underlying test failures; and

- Limits the ability to fully study brake particle emissions.

TriboLab HD:

- Reduces material costs and shortens time-to-market;

- Tests critical components earlier in the development cycle;

- Simplifies test design, setup, and completion - can begin testing on day one;

- Enables easy monitoring and comparison of test runs; and

- Supports brake particle collection and analysis.

Accelerating the Development Cycle

As engine types evolve and environmental concerns become more critical, new brake materials must meet increasingly stringent performance, comfort, cost, and safety requirements. The standard development cycle for these materials may take up to five years to bring these materials to market.

Specifically designed to help increase agility and reduce development time, the TriboLab HD high-torque friction material tester allows more rapid development of new materials at the cutting edge of the industry. Developers can achieve superior results by concentrating on only the best formulations — an extreme advantage in such a competitive market.

TriboLab HD offers significant improvements over currently available in-lab testing:

- Measure COF accurately at high loads and speeds with up to 50 Nm torque;

- Reduce material testing costs with coupons;

- Simulate SAE J2522 test scenarios for all-purpose roads;

- Maintain temperature during fade testing with direct heating up to 550°C; and

- Integrate seamlessly with third-party particle analyzers.

Providing Exceptional Performance and Ease of Use

TriboLab HD makes it easy to get meaningful test results. Its combination of advanced hardware and intuitive software is designed specifically for automotive friction materials testing and includes:

- Heavy-duty motor to provide 8.5 MPa pressure, applied at 120 km/hr;

- High-precision, low-noise, all-in-one load/torque sensor;

- In-situ heating to maintain temperature in between snubs and externally heat the rotor;

- Robust hardware to withstand the harsh demands of friction material testing and simulate real-world conditions; and

- Pre-programmed and easily modified scripts expedite testing and analysis.

(See the "Software" tab for more details)

Enabling Particle Emissions Studies

The health and safety implications of airborne particles created by brake wear are gaining international attention. As regional environmental standards develop, brake component approval regulations and consumer expectations will become increasingly strict. Developers will need to change the physical properties of new formulations or modify existing formulations to reduce particle emissions.

The TriboLab HD particle collection chamber seamlessly integrates with third-party particle analyzers to make it easy for manufacturers to study the entire wear process.

Critical functions for precise and repeatable in-lab wear studies include:

- The collection of particles from conventional and newly developed materials;

- Reliable, representative, and repeatable sampling and characterization of brake wear particles;

- The measurement of particle mass, number, and concentration in variable, highly dynamic conditions; and

- Particle size measurement over a large size range (<10 nm – 10 µm).

TriboLab HD addresses these functions with:

- Easy integration of commercial particle analyzers;

- Optimum control of parameters and simulation of different driving conditions and regulatory standards;

- Simulation of abrasion processes leading to direct emissions of particulates with high accuracy/authenticity; and

- Easily cleanable surfaces to reduce contamination and increase the reliability of environmental particle screening.

Making Testing Easy

The TriboLab HD's dedicated brake materials testing software features extremely versatile operator ease of use and pre-set push-button tests to expedite operation, test development, and reporting:

- Pre-programmed scripts based on simulated “AK Master” standards are available so productive testing can start on day one;

- Test specimen parameters are automatically converted from vehicle parameters, which then updates the 100+ pre-programmed test scripts;

- Results are easily processed whether running a single section or the full suite of SAE J2522 tests;

- Data between runs is easy to compare since it is always presented in the same format; and

- The ability to modify test scripts allows users to easily create unique tests to meet customized requirements.

Frequently Asked Questions

TriboLab HD is specifically engineered for heavy-duty applications with robust drives and high load capacities. The platform supports up to 50 N∙m torque at 3300 rpm and up to 2 kN normal load. Additional specifications can be found in the system brochure.

Standard fixtures hold coupons or segments of pad and rotor materials. Custom fixtures for larger components should be discussed with Bruker experts.

TriboLab HD is widely used in industries such as automotive, aerospace, and manufacturing for evaluating the tribological performance and durability of friction materials under demanding conditions.

TriboLab HD offers modular hardware options that can be tailored to specific test protocols, sample sizes, and industry requirements. Users can then adjust motion profiles, contact pressures, temperatures, and cycle sequences in the software.

Yes. The software provides pre-programmed sequences for industry protocols such as SAE J2522 and AK Master–style procedures. Parameters can be edited to match target conditions.

The chamber includes ports to connect third party particle collection systems. Data from external analyzers can be correlated with in-situ friction and temperature measurements.

Yes, the system supports automated test protocols and batch reporting.

More About Bruker's Mechanical Testing and Tribology Technology

TriboLab platforms support standard rotary, reciprocating, block-on-ring, four-ball, scratch, and indentation tests. Common methods include ASTM G99, G133, G77, D4172, and C1624. Equivalent ISO methods can typically be addressed through the same hardware and scripting.

The exact scope of the included installation and operator training depends on region and contract. Confirm details with your Bruker representative.

All TriboLab systems are modular. You can select drives, force and torque sensors, environmental chambers for temperature and humidity, liquid and electrochemical options, and advanced sensors to meet your application needs. If you are not sure which modules meet your needs, our experts can help.

Bruker provides applications consulting, troubleshooting, and best practice guidance, along with optional service plans for ongoing support, maintenance, and training.

Contact us to arrange a demonstration or submit samples for an evaluation tailored to your test geometry and materials.