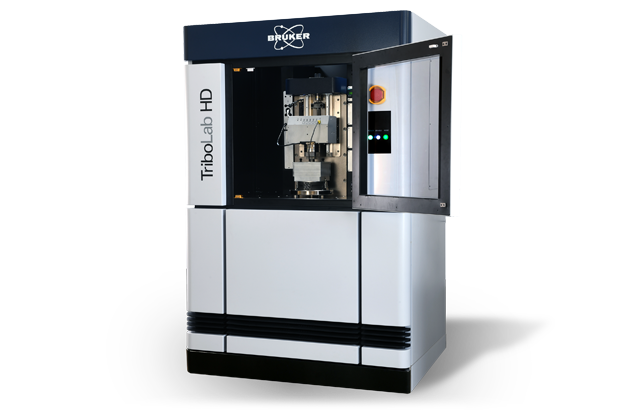

TriboLab HD高扭矩摩擦材料测试仪

TriboLab HD

TriboLab HD高扭矩摩擦材料测试仪能够进行比以前在实验室环境中更精确、更可重复的制动摩擦、磨损和颗粒排放研究。

该系统采用了先进的技术,提供了广泛的测试能力,对测试参数和条件的灵活控制,以及提供了更大的扭矩,同时还支持制动过程的颗粒分析。凭借在实验室中模拟SAE J2522协议和其他标准的能力,TriboLab HD提供了在制动材料开发过程中早期做出关键决策所需的数据,弥补了刹车片和刹车片材料在实验室设计与测功机测试之间的差距。

TriboLab HD独有的设计使工程师和制造商能够减少开发时间,满足新兴标准和消费者需求,同时降低成本并保持领先于竞争对手。

To learn more, continue reading, contact us, or see FAQs about this product.

连接实验室设计与测功机测试

通常在实际道路车辆测试之前,测功机测试是在模拟驾驶条件下评估新型刹车片配方的标准方法。

TriboLab HD在开发周期早期的法规遵从性或认证所需的各种驾驶条件下提供了全面的材料测试的显著优势。这使得研究人员能够在昂贵的测功机测试之前对材料配方进行更大程度的微调。

测功机测试:

- 如果刹车片材料不满足标准要求将增加许多额外成本;

- 一般发生在研发周期后期;

- 需要数天时间来完成测试;

- 只能提供测试机理的有限想信息;

- 难以全面分析刹车颗粒排放行为。

TriboLab HD高扭矩摩擦材料测试仪:

- 降低材料成本,缩短上市时间;

- 在开发周期的早期测试关键组件;

- 简化测试设计、设置和完成-可以在第一天开始测试;

- 实现测试运行的轻松监控和比较;

- 支持制动颗粒的收集和分析。

加速研发流程

随着发动机的发展和环境问题变得越来越重要,新型制动材料必须满足越来越严格的性能、舒适性、成本和安全要求。这些材料的标准开发周期可能需要长达五年的时间才能将这些材料推向市场。

TriboLab HD高扭矩摩擦材料测试仪专为提高灵活性和缩短开发时间而设计,可在行业前沿领域更快地开发新材料。开发人员可以通过只专注于优化配方来获得卓越的结果,这在竞争如此激烈的市场中是一个大优势。

TriboLab HD比目前可用的实验室测试提供了显著的改进:

- 在高负载和高速度下精确测量COF,扭矩高达50 Nm;

- 使用小样品降低材料测试成本;

- 模拟通用道路的SAE J2522测试场景;

- 直接加热至550°C,并在退化测试期间保持温度;

- 与第三方粒子分析仪无缝集成。

提供卓越的性能和易用性

TriboLab HD可以轻松获得有意义的测试结果。它结合了先进的硬件和直观的软件,专为汽车摩擦材料测试而设计,包括:

- 高载电机,提供8.5兆帕的压力,以120公里/小时的速度运行;

- 高精度、低噪音、一体式负载/扭矩传感器;

- 原位加热以保持点刹之间的温度,并从外部加热转子;

- 坚固的硬件,能够承受摩擦材料测试的苛刻要求,并模拟真实世界的条件;

- 预先编程和易于修改的脚本加快了测试和分析。

(有关更多详细信息,请参阅“软件”选项卡)

实现颗粒排放研究

刹车片摩擦产生的在空气中传播的颗粒物对健康和安全的影响正受到国际关注。随着地区环境标准的发展,刹车片部件的批准规定和消费者的期望将变得越来越严格。开发商需要改变新配方的物理特性或修改现有配方,以减少颗粒物排放。

TriboLab HD颗粒收集室与第三方颗粒分析仪无缝集成,使制造商能够轻松研究整个磨损过程。

精确和可重复的实验室磨损研究的关键功能包括:

- 从传统和新开发的材料中收集颗粒;

- 制动器磨损颗粒的可靠、有代表性和可重复的取样和表征;

- 在可变的、高度动态的条件下测量粒子的质量、数量和浓度;

- 在大尺寸范围(<10 nm–10µm)内进行粒度测量。

TriboLab HD通过以下配置实现这些功能:

- 易于集成的商用颗粒分析仪;

- 参数的优化控制以及不同驾驶条件和监管标准的模拟;

- 以高精度/真实性模拟直接导致颗粒物排放的磨损过程;

- 易于清洁的表面,减少污染,提高环境颗粒物筛选的可靠性。

让测试变简单

TriboLab HD的专用刹车测试软件具有通用的易用性和预设按钮测试功能,可加快操作、测试开发和生成报告:

- 基于模拟“AK Master”标准的预编程脚本,可以在第一天就开始测试;

- 试样参数自动从车辆参数转换而来,然后更新100多个预先编程的测试脚本;

- 无论是单独测试还是全套SAE J2522测试,结果都很容易处理;

- 运行之间的数据很容易比较,因为它总是以相同的格式显示;

- 修改测试脚本的能力允许用户轻松创建独特的测试,以满足定制的需求。

Frequently Asked Questions

TriboLab HD is specifically engineered for heavy-duty applications with robust drives and high load capacities. The platform supports up to 50 N∙m torque at 3300 rpm and up to 2 kN normal load. Additional specifications can be found in the system brochure.

Standard fixtures hold coupons or segments of pad and rotor materials. Custom fixtures for larger components should be discussed with Bruker experts.

TriboLab HD is widely used in industries such as automotive, aerospace, and manufacturing for evaluating the tribological performance and durability of friction materials under demanding conditions.

TriboLab HD offers modular hardware options that can be tailored to specific test protocols, sample sizes, and industry requirements. Users can then adjust motion profiles, contact pressures, temperatures, and cycle sequences in the software.

Yes. The software provides pre-programmed sequences for industry protocols such as SAE J2522 and AK Master–style procedures. Parameters can be edited to match target conditions.

The chamber includes ports to connect third party particle collection systems. Data from external analyzers can be correlated with in-situ friction and temperature measurements.

Yes, the system supports automated test protocols and batch reporting.