Choose the Right 3D Optical Profiler For Your Needs

Worldwide Leadership in 3D Non-Contact Surface Measurement & Inspection Solutions

All Bruker 3D optical profilers share the same core capabilities and features across the entire product line. These include high resolution and dependable performance for precise surface measurements, easy-to-use automation for streamlined setup and workflows, and Bruker-exclusive and industry-best technologies that deliver consistent, reliable results.

These shared elements ensure that 𝙖𝙡𝙡 𝙢𝙤𝙙𝙚𝙡𝙨 include the essential capabilities and measurement quality needed in both research and production environments, offering:

🞄 Sub-nanometer vertical resolution, independent of magnification

🞄 Non-contact, non-destructive measurement across smooth, rough, transparent, or reflective surfaces

🞄 Full compliance with ISO 25178 for areal texture and functional surface analysis

Building on this foundation, the range includes models with advanced and specialized options for different measurement requirements and environments. Below, you can read detailed model overviews and compare capabilities and features across the product line.

Practical Considerations for Selecting a 3D Optical Profiler

The specific conditions of your application — such as sample size, measurement complexity, and automation needs — are the key drivers in selecting the right system. When comparing instruments, several factors often influence the decision, including:

- Sample size & height – Will you measure small parts or large components?

- Platform type – Benchtop for compact setups; floor-standing for larger samples.

- Measurement needs – Single vs. multiple measurements, angled surfaces.

- Automation level – From manual to fully automated workflows.

Use the comparison table and system details below to narrow your options, or get personalized recommendations for your application.

At-a-Glance 3D Optical Profiler Comparison:

| Platform Type | Stage Size | Max. Sample Height | Automation | Ideal for |

Benchtop | 150 mm | 100 mm | Low | Straightforward, high-precision surface metrology of small samples and small areas of interest | |

Benchtop | 150 mm | 100 mm | Medium | Routine metrology of small samples when ease of use and larger areas of interest are important | |

Benchtop | 150 mm | 100 mm | High | Small-sample metrology when high performance, automated features, and/or compactness are important | |

Floor-Standing | 300 mm | 100 mm | High | Highest-resolution, high-throughput metrology of limited-height parts in nearly any environment, from research labs to production facilities | |

Floor-Standing | 300 mm | 300 mm | High | Ultimate flexibility in part size, surface access, ease of use, and automation for R&D labs and production facilities | |

Floor-Standing | 600 mm | Panel thickness 0.6–1.6 mm | High | High-throughput PCB metrology | |

Floor-Standing | 200 mm | 100 mm | High | Metrology of data storage sliders |

ContourX Benchtop WLI Systems

With a wide range of configurations, analytical options, objectives, and measurement modes, our ContourX suite of benchtop profilometers provides gage-capable, quantitative 3D surface characterization for nearly any surface. Continue reading or download the ContourX benchtop product line brochure to learn more about each system.

A streamlined benchtop 3D optical profiler, ContourX-100 delivers Bruker’s renowned WLI performance at an accessible price point. It offers full core functionality, including nanometer resolution and broad surface compatibility, in a compact, economical platform. ContourX-100 is an easy-to-use high-precision tool that provides unbeatable value for labs and small production facilities.

- Sample size capacity: 150 mm stage for samples of height ≤100 mm

- Sample types: General small parts, such as coupons, film step samples, small optics, etc.

- Automation: Automated turret (optional) and focus/illumination; Manual XY stage, tip/tilt (stage), and calibration

- Ideal for: Straightforward, high-precision surface metrology of small samples and small areas of interest

As the mid-range ContourX benchtop profiler, ContourX-200 balances advanced characterization, customizable options, and ease of use. It adds select automation features beyond the ContourX-100 capabilities, such as a motorized XY stage, automated stitching for large-area mapping, and an Advanced Find Surface function. ContourX-200 is a workhorse system that is user-friendly for a diverse range of applications and industries.

- Sample size capacity: 150 mm stage for samples of height ≤100 mm

- Sample types: Broad compatibility for polished samples, MEMS, tooling surfaces, etc.

- Automation: Automated XY stage, turret (optional), and focus/illumination; Manual tip/tilt (stage) and calibration

- Ideal for: Routine metrology of small samples when ease of use and larger areas of interest are important

ContourX-500 combines top-tier WLI technology with benchtop convenience. It is a full-featured, space-saving solution for complex measurement needs, including varied parts, angled surfaces, large-area stitching, and recipe-driven operation. Equipped with an encoded XY stage, auto tip/tilt optical head, vibration isolation, and the full suite of Bruker’s analysis software, ContourX-500 delivers quick, precise results for applications from precision machining QC to MEMS R&D.

- Sample size capacity: 150 mm stage for samples of height ≤100 mm

- Sample types: Broad compatibility for smaller wafers, precision machined parts, biomedical devices, etc. Can accommodate angled or sloped surfaces with tip/tilt capability.

- Automation: Automated encoded XY stage, turret (optional), and focus/illumination, and tip/tilt (head); Manual calibration

- Ideal for: Small-sample metrology when high performance, automated features, and/or compactness are important

Floor-Standing WLI Systems

Our general-purpose floor-standing WLI solutions feature integrated vibration isolation and larger stage capacity than benchtop models. These platforms combine advanced automation and performance with user-friendly operation and analysis, making them well suited to both laboratory and production environments. Continue reading to learn more about the key features of each system.

ContourX-1000 is a self-calibrating floor-standing WLI system that delivers ultimate measurement performance with push-button simplicity for any operator. It is a fully automated, high-throughput 3D profiler that integrates exclusive hardware (patented tip/tilt head, dual-LED illumination, integrated laser reference) and one-click automation routines—resulting in reliably accurate and precise measurements. ContourX-1000 provides the fastest time-to-results, high repeatability, and greater ease-of-use for development and production applications.

- Sample size capacity: 300 mm access for samples of height ≤100 mm

- Sample types: Virtually any surface for parts with height ≤100 mm, from super-smooth optics to rough machined parts

- Automation: Automated encoded XY stage, turret (optional), focus/illumination, tip/tilt (head), and calibration (optional)

- Ideal for: Highest-resolution, high-throughput metrology of limited-height parts in nearly any environment, from research labs to production facilities

NPFLEX-1000 brings unprecedented flexibility for large or uniquely-shaped parts, with a robust bridge design, 300 mm vertical clearance, and a swivel measurement head. In the cases of heavy parts, unwieldy shapes, and barely accessible surfaces, NPFLEX-1000 is often the only WLI platform that can deliver results. Its ability to perform fast, automated roughness measurements on large parts and steep slopes is especially valuable for the automotive, aerospace, and medical device industries.

- Sample size capacity: Extra-large and flexible, with an open gantry and 300 mm vertical clearance

- Sample types: Small coupons up to large, complex components

- Automation: Automated encoded stage, turret (optional), focus/illumination, and calibration (optional)

- Ideal for: Ultimate flexibility in part size, surface access, ease of use, and automation for R&D labs and production facilities

Industry-Specific Turnkey WLI Solutions

Our turnkey systems are purpose-configured to meet industry-specific metrology requirements. Continue reading to explore solutions for PCB panel manufacturing and HDD slider metrology.

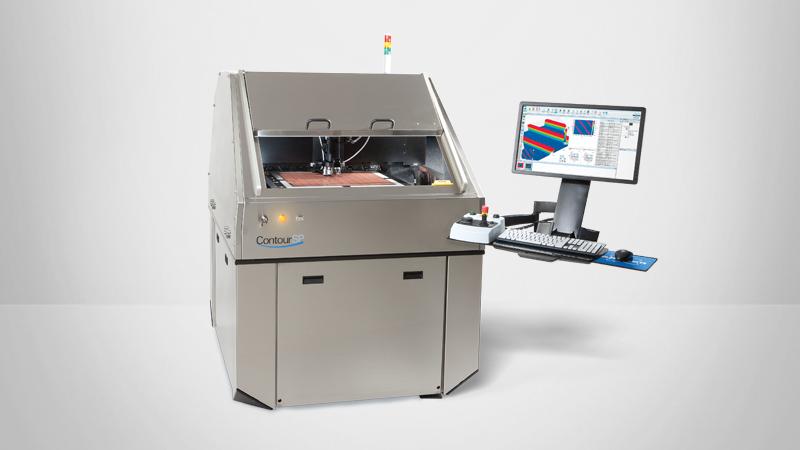

Designed for semiconductor packaging lines, the ContourSP is a large-panel WLI system that doubles throughput for HDI PCB substrate inspection while maintaining nanometer-level precision. It enables rapid, inline production control with production-oriented features, such as fiducial alignment and pattern recognition. ContourSP is a purpose-built system optimized to meet the speed, reliability, and measurement requirements of PCB panel metrology.

- Sample size capacity: Extra-large, up to 600x600 mm

- Sample types: PCB panels

- Automation: Automated stage, turret (optional), focus/illumination, and calibration

- Ideal for: High-throughput PCB metrology

HD9800+ is a large-format optical profiler for the data storage industry. As the most advanced inline profiler for slider PTR and flatness, the system combines full automation and self-calibration to ensure long-term stability. HD9800+ is a turnkey solution for HDD sliders, pre-optimized for industry-relevant critical measurements.

- Sample size capacity: 200 mm standard stage

- Sample types: Hard disk drive sliders in batches

- Automation: Automated stage, turret (optional), focus/illumination, and calibration

- Ideal for: Metrology of data storage sliders