Flour, Milling & Bakery

Analysis of Flour, Milling and Bakery Products

Cereals are the cornerstone of the daily nutrition for most people around the world. The Flour & Milling industry plays an essential part in turning cereals into flours for human consumption.

Bruker offers solutions for the Flour & Milling industry for the analysis of wheat, various flour types as well as co-products based on FT-NIR Spectroscopy - from small, easy-to-use benchtop spectrometers to complete online monitoring systems.

- Wheat intake: Know what you get

- Wheat tempering: Maximize the yield

- Flour quality: Monitor the final product

Ready to use calibration packages give you results in seconds and are a highly cost-effective solution compared to conventional testing methods.

XRF is a fast, nondestructive technology for elemental analysis of macro-nutrients, micro-nutrients, and heavy metals. Bruker’s Elemental Analyzer portfolio includes high-throughput lab-based ED-XRF and WD-XRF, point-and-shoot handheld XRF, micro-XRF, and ultra-trace analysis TXRF spectrometers.

Foreign bodies found in feed products need to be identified to be able to determine their source for taking corrective action. XRF and FT-IR quickly identify these small physical contaminant materials on the production floor or in the lab. Whereas XRF spectroscopy is ideal for metals, ceramics, stones and glass, the complementary FT-IR technology works best for plastics, rubbers, and other organic materials.

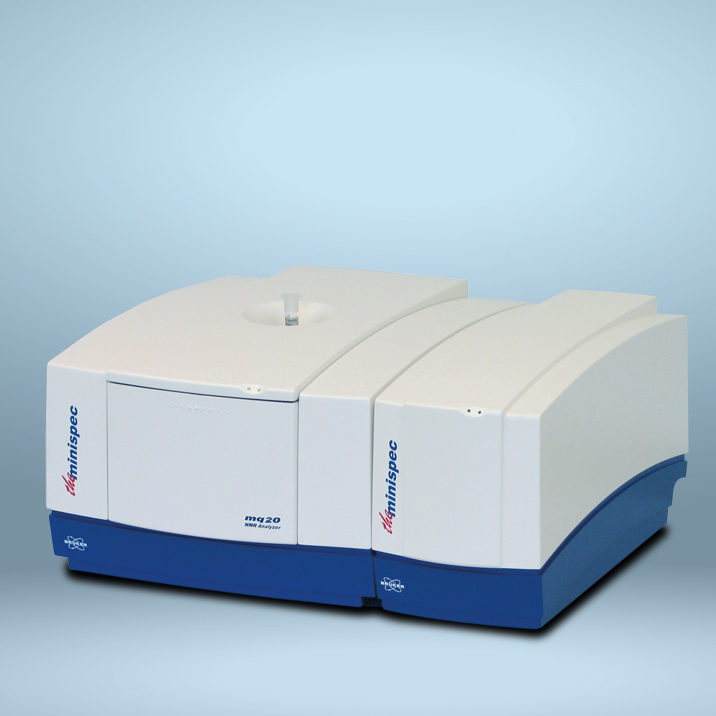

TD-NMR relaxometry can be applied to determine the water mobility in bread and how it can be correlated to different performance (freshness/softness) of the final product. Protons inside a starch granule have a lower mobility and, therefore, lower relaxation times than protons outside the granule. The correlation between proton mobility on a molecular scale and the macroscopic textural properties of the final product, make TD-NMR a suitable technique to predict product quality.

Related Videos

How to use handheld and portable XRF (HH-XRF, pXRF) to to identify physical contamination in food products

How to use XRF spectral fingerprinting to ID physical contamination in food products