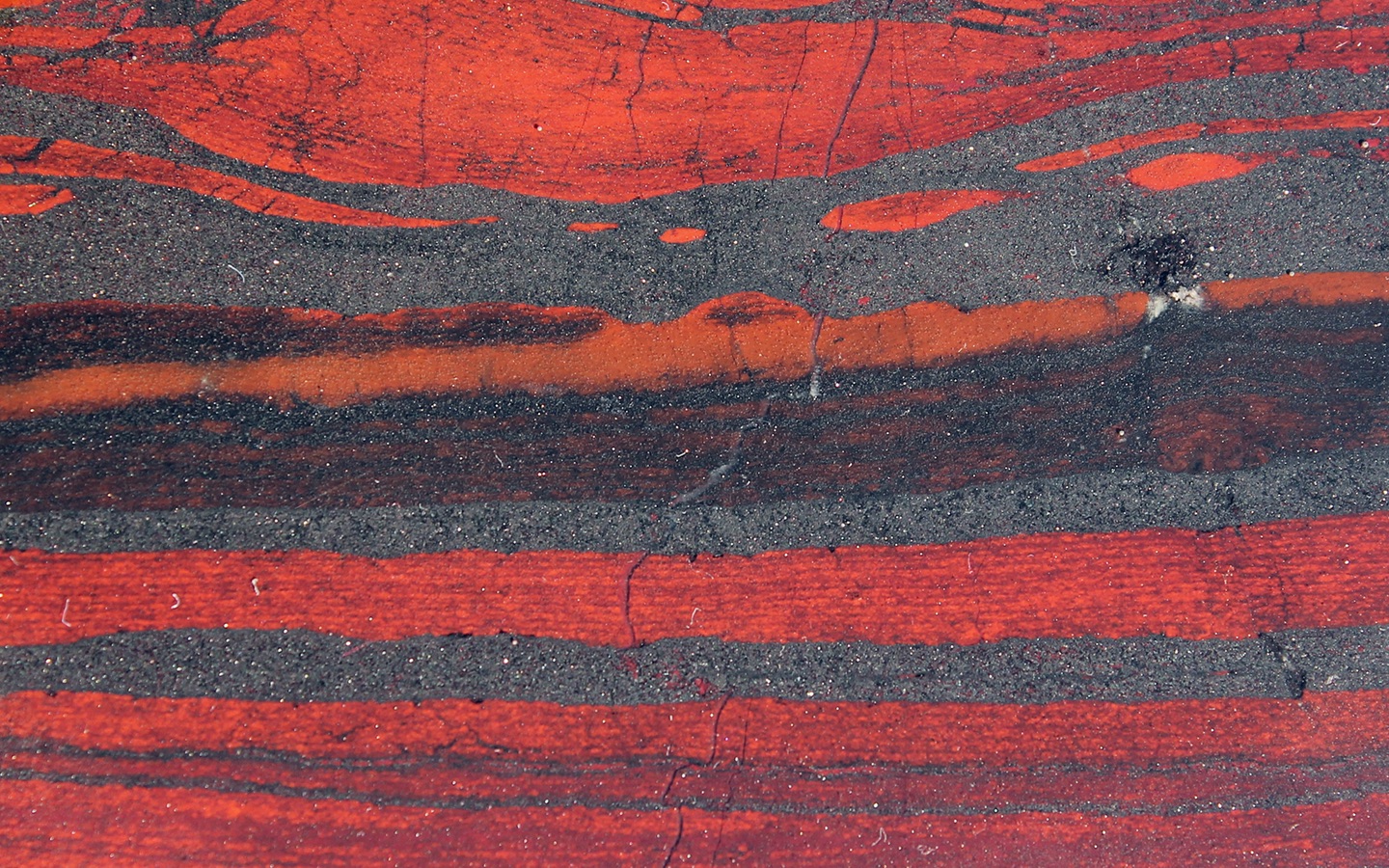

Iron Ore Exploration and Production

Proactive Analytical Solutions for the Entire Iron Ore Value Chain

The iron ore industry is dedicated to safety and environmental protection while maintaining profitability. Iron ore mining is highly competitive with a continuous focus on delivering value through efficiency. Explore Bruker’s full range of analytical solutions to support iron ore from exploration to remediation and from the mine face through beneficiation.

Collecting Data in the Field with Portable and Handheld XRF

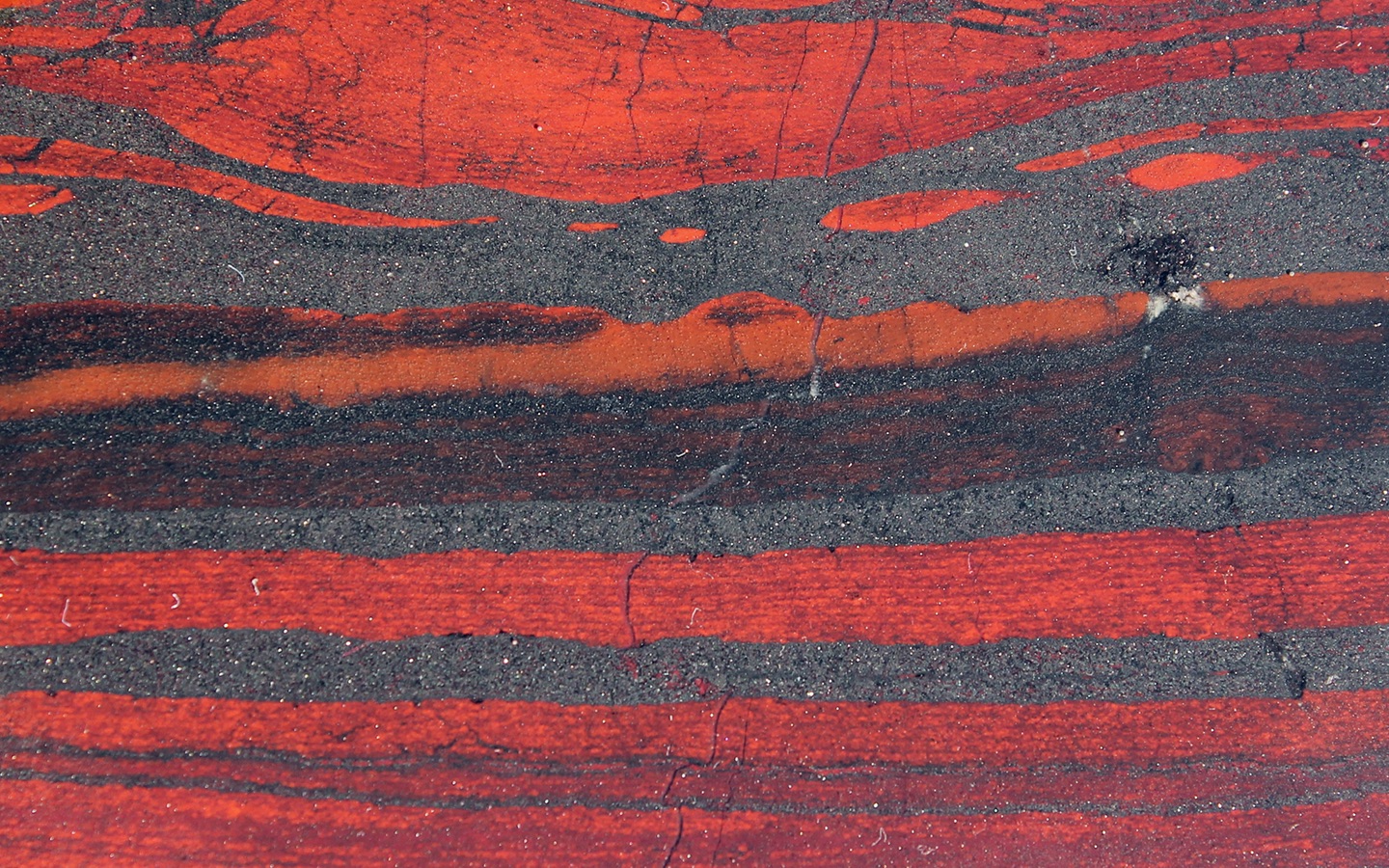

Iron ore exploration relies on preliminary grade assignment and preliminary assessment of penalty elements. Most exploration is near-mine brownfield exploration or reassessment of historic resources to identify high-grade drilling targets. Bruker’s field portable solutions provide more information to exploration teams, quicker. This enables the targeting of exploration activities with more data. For example:

Core scanning with the S1 TITAN is a fast and non-destructive technique for to assess elemental variations and assign preliminary cutoff grade delineations for core. Learn more about core scanning.

The CTX or S2 PUMA are ED-XRF that can be deployed in the field or in field-adjacent laboratories. The S6 Jaguar is a benchtop WD-XRF providing the highest quality elements results from XRF in a compact package. Learn more about geochemistry with XRF.

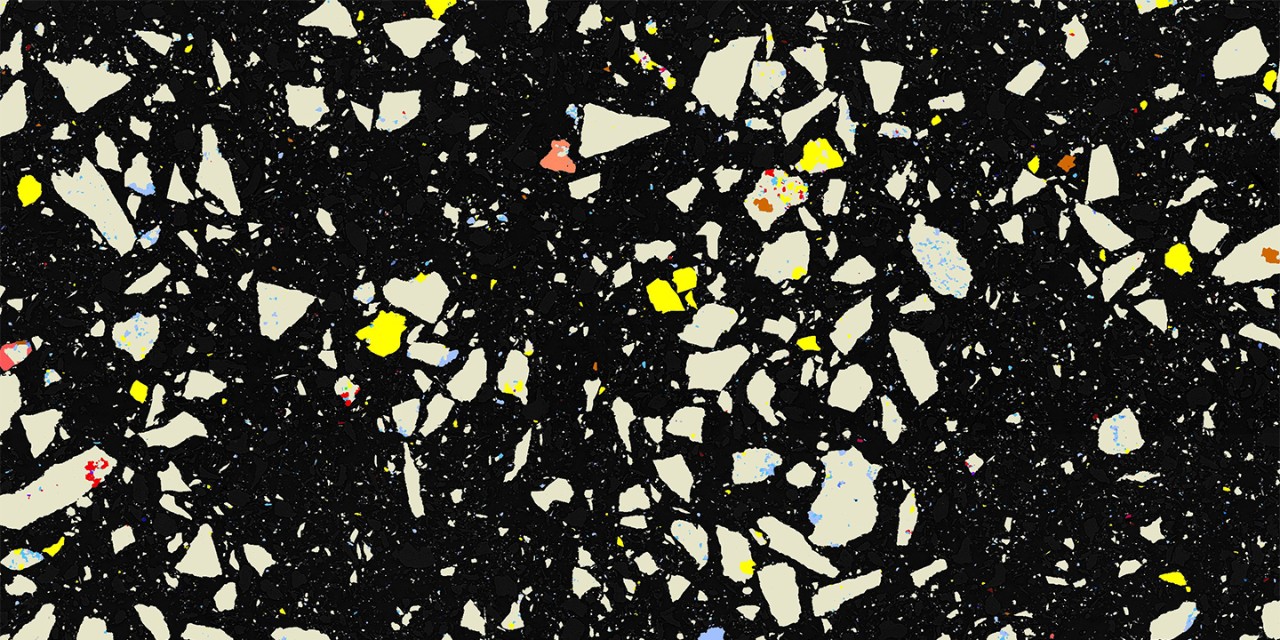

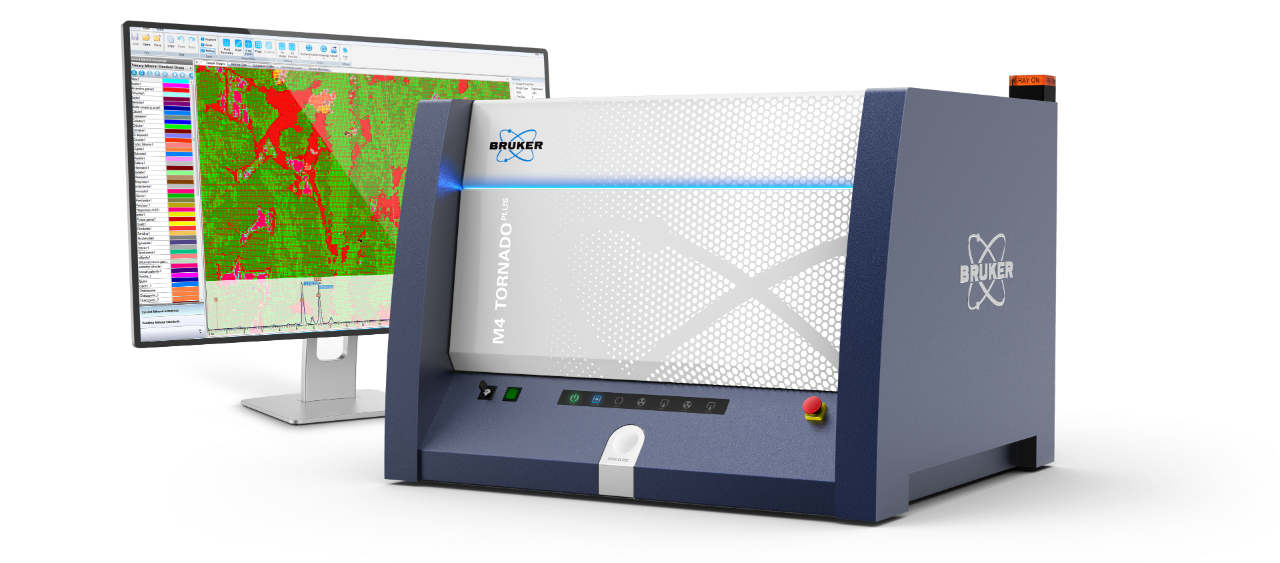

Automated mineralogy can be deployed on-site or in field-adjacent laboratories with AMICS on a compact or desktop SEM. Learn more about process mineralogy.

Grade Control for Iron Ore

Robust grade control is critical for realizing efficiencies in mining operation and processing for iron ore. The efficient and accurate measurement of elemental and mineral constituents of ore is required for blending and sorting workflows. Innovative placement of grade control operations may realize the benefits of predictive models of upgradability. Mineral textural information from automated mineralogy is critical for optimizing the commutation circuit of an iron mine. Bruker’s experts have helped mine planners, geologists, geometallurgists, and engineers realize real process and quality control improvements.

Explore XRF Options

| S1 TITAN 800 | Portable XRF | Portability and power define the S1 TITAN, with a rugged case, Titan Detector Shield™ and GeoExploration calibration. Portable XRF is ideal for on-site analysis, exploration, and core scanning. |

| CTX | Countertop XRF | The CTX is a rugged and portable single-sample countertop XRF with battery backup, safety interlocked lid, Titan Detector Shield™ and push-button operation that is ideal for quick-look grade control and process control. |

| S2 PUMA | Benchtop ED-XRF | The S2 PUMA Series 2 is the standard for laboratory ED-XRF analysis, equipped with the intuitive TouchControl™ interface and XY robotic multi-sample or carousel sample changer. |

| S6 JAGUAR | Benchtop Sequential WD-XRF | The S6 JAGUAR provides WD-XRF performance in a compact package ideal for any laboratory analysis. |

| S8 TIGER | Sequential WD-XRF | The S8 TIGER Series 2 sequential WDXRF provides outstanding superior analytical performance for the most demanding mineral and mining applications. |

Analysis of Penalty Elements with Fused Beads

Elements other than iron (Fe) dilute the grade of ore and are penalized at the smelter. For example, phosphorous (P) or sulfur (S) in iron ore can cause brittleness in high concentrations. Silica (Si) and aluminum (Al) can change the molten properties of iron and impede the smelting process. X-ray fluorescence (XRF) is an effective tool in determining penalty elements in all phases of iron ore mining, from the pit to the smelter. Preparing samples as fused beads eliminates the mineralogical effects of samples and enables a more accurate comparison of samples.

Automated and Custom Solutions

Systems integration of scientific instrumentation into online and inline processes for iron ore requires a components partner that understand both the operating environment and analytical challenges of the segment. Bruker is that partner. Bruker is a trusted partner providing x-ray and optical components for automated sample processing and analysis, conveyer belt analysis, custom instrumentation, and unique solutions. Bruker has partnered with companies of all sizes, from startups to the world’s largest systems integrators, to make visionary workflows and unique analysis become a reality. Contact Bruker’s development experts to discuss your project today.

Trace Element and Heavy Metals Monitoring in Mine Effluent

Monitoring for heavy metals in mine effluent and discharged waters has become a core competency for iron ore mines globally. Water passing through waste and tailings piles will accumulate copper, iron, manganese, lead, selenium, and zinc. Total reflection X-ray fluorescence (TXRF) is an emerging tool for the identification and quantification of trace elements and heavy metals for mining operations and remediation. This innovative technology can provide accurate quantification in the PPB range for many elements with simple sample preparation, no dilution, and no consumable gasses.

Publications Related to Iron Ore

- 2019 - Earth Science Informatics: Development of a machine vision system using the support vector machine regression (SVR) algorithm for the online prediction of iron ore grades

- 2018 - Minerals: (Open Access) A Geometallurgical Approach to Tailings Management: An Example from the Savage River Fe-Ore Mine, Western Tasmania

- 2015 - Applied Surface Science: XPS and FTIR spectroscopic study on microwave treated high phosphorus iron ore

- 2015 - Powder Technology: Thermally assisted liberation of high phosphorus oolitic iron ore: A comparison between microwave and conventional furnaces

- 2015 - Iron Ore: 3 - XRD analysis and evaluation of iron ores and sinters

- 2014 - Ore Geology Reviews: Quantitative mineralogical and chemical assessment of the Nkout iron ore deposit, Southern Cameroon

- S6 JAGUAR Quick Quality Control of Iron Ore Grades