Dektak XTL

Dektak XTL

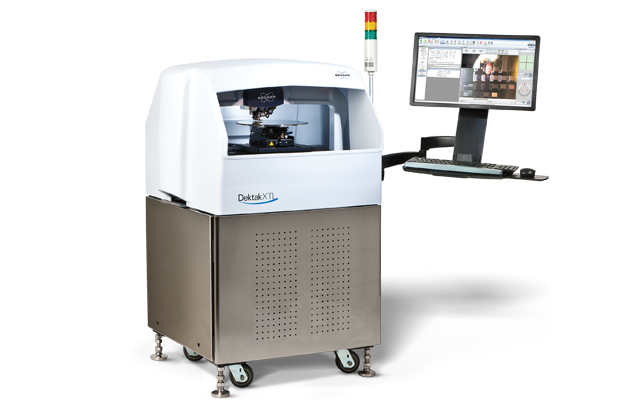

The Dektak XTL™ stylus profilometer accommodates samples up to 350mm x 350mm, bringing legendary Dektak® repeatability and reproducibility to large-format wafer and panel manufacturing. The Dektak XTL features pneumatic vibration isolation and a fully enclosed workstation with easily accessible interlocking door, making it ideal for today’s demanding production floor environments. Its dual-camera architecture enables enhanced spatial awareness, and its high level of automation maximizes manufacturing throughput.

Industry's Best Automation and Analysis Software

Enhanced software features make the Dektak XTL the most powerful, easiest to use stylus profiler available. The system utilizes Vision64 software that enables unlimited measurement sites, 3D mapping, and highly customized characterization with hundreds of built-in analysis tools. Vision Microform software also measures shapes, such as radius of curvature. Pattern recognition minimizes operator error and enhances measurement location accuracy. The all-in-one software package combines data collection and analysis with an intuitive workflow.

Unmatched Stylus Technology

The Dektak XTL builds upon over 50 years of stylus expertise and application customization for production facilities to meet the stringent industry roadmaps of both today and tomorrow. The 300-millimeter, high-accuracy encoded XY staging gives manufacturers a reliable tool to meet stringent gage R&R requirements. Dektak’s Dual Camera Control with high-magnification dual view cameras offers enhanced spatial awareness. Point-and-click positioning in the live video allows operators to quickly place samples at the right location for quick and easy measurement setup and automation programming. The system’s large interlocked door provides safe and easy access for sample loading/unloading.

Other hardware features include:

- Single-arch architecture and integrated vibration isolation for industry-leading performance

- Quick-change self-aligning stylus

- High-accuracy encoded XY stage for faster automated data collection

- N-Lite low force with Soft Touch technology and 1mm measurement range can be used simultaneously to measure delicate and high-vertical range samples