AutoMET Software

AutoMET’s recipe-based AFM and AFM-IR workflow automation ensures consistent, repeatable data acquisition, reduces operator dependency, and streamlines complex measurement routines. AutoMET® provides exceptional ease of use and adaptability for critical‑to‑quality measurements in production, QA/QC, or other high‑volume metrology applications, such as machine learning-based studies.

(B) Recipe window showing wafer-based layout for precise, user-defined X,Y measurement locations.

Powerful Capabilities

AutoMET delivers:

- Adaptability — for sample type, measurement settings, number of measurements, scan sizes, and the choice of scan modes.

- Ease of Use — with optical and AFM image pattern recognition, tip-centering, full-wafer (up to 300 mm) or grid-mapping support, and image-placement accuracy within tens of nanometers.

- Alignment Support — to align sample to probe and to perform alignment corrections.

- Recipe Flexibility — with comprehensive yet simple recipe writing in engineer mode for advanced users.

- Operator Convenience — with a dedicated interface to perform complex recipe-guided measurements at the push of a button.

Straightforward User Experience

AutoMET supports users of all experience levels with intuitive tools for recipe creation, streamlined operation, and automated workflows.

Engineer Mode

AutoMET recipes use a simple but powerful modular structure. Each site, measurement, and analysis is a block that can be created, reused, and linked in any way the engineer chooses.

The software includes an intuitive and simple recipe-writing environment that makes it extremely easy to reduce complex measurement routines to simple, push-button operations. During recipe creation, the engineer is prompted to:

- Choose sites of interest

- Define measurements per site

- Set analyses per measurement

Operator Mode

Operators of all experience levels can obtain detailed, accurate measurements on thousands of samples by running pre-defined recipes. Designed for simplicity and efficiency, AutoMET’s operator mode consists of only two functions: conducting the probe setup and running a pre‑defined recipe. An operator simply moves through the probe setup procedure, makes the appropriate selections, and clicks on the Run Recipe button to start data collection.

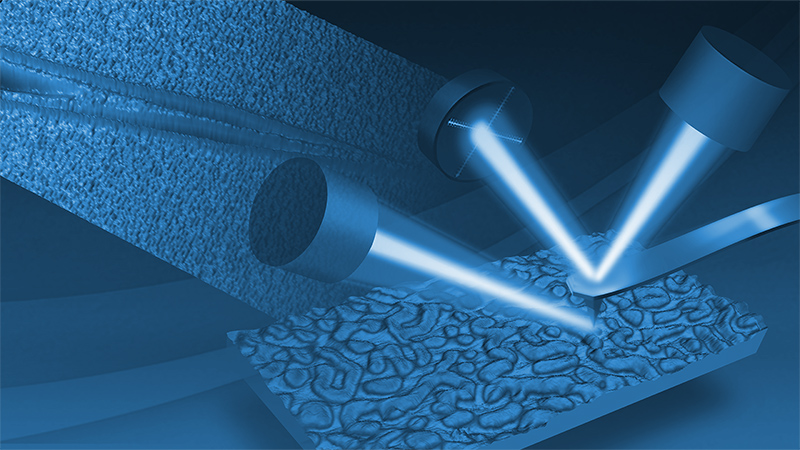

Unique Push‑Button Operation for AFM‑IR

AutoMET with Dimension IconIR or Dimension IconIR300 provides first-and-only automated photothermal AFM-IR measurement capabilities. This combination supports recipe-driven, push-button nanoscale chemical imaging, AFM imaging, and KLARF-based navigation. IR spectroscopy steps at pre-defined locations can also be added within automated recipes. This measurement convenience allows you to perform repeated routine analyses consistently and without constant oversight.