3D XRM for Material Science

A new dimension for microscopy

Bruker 3D X-ray Microscopes (XRM) combine micro-computed tomography (micro-ct) hardware with specialized software into a complete microscopic visualization solution. Ranging from micro-resolution benchtops to nano-resolution floor standing instruments, Bruker XRM solutions provide the perfect balance of ease-of-use and power.

From measuring the porosity in geological specimens to the thickness of multiple coatings on pharmaceutical tablets or the on-chip and board level interconnect structure of circuits, XRM allows rapid multiscale analysis. The non-destructive nature of XRM allows validation of component integrity bringing QC of manufacturing techniques such as additive manufacturing to a new level.

Bruker’s software provides simple push button interfaces for technicians and novice researchers and exceptional depth for experts looking to push the boundaries of their samples and the technique. Reconstruction is accomplished with the latest GPU driven algorithms providing results from large datasets in a fraction of the time. The included analysis package allows both qualitative visualizations and quantitative regressions.

Materials Science XRM Specifications

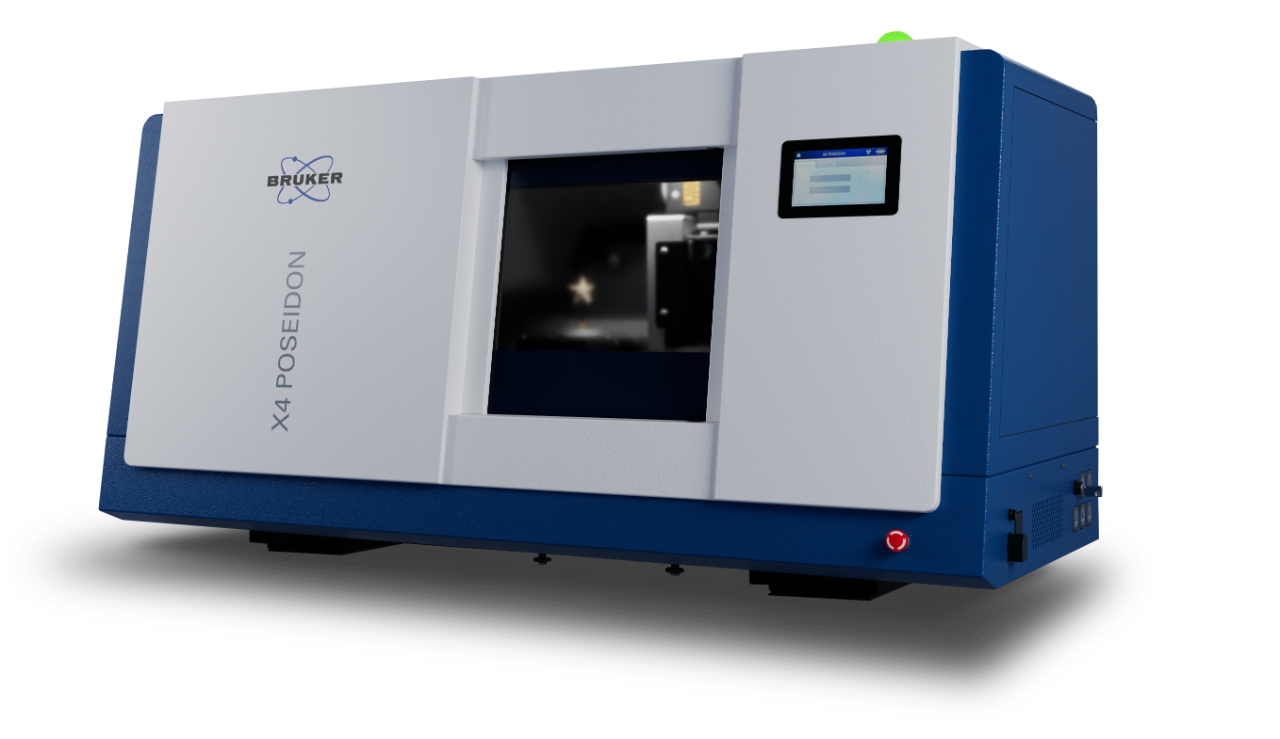

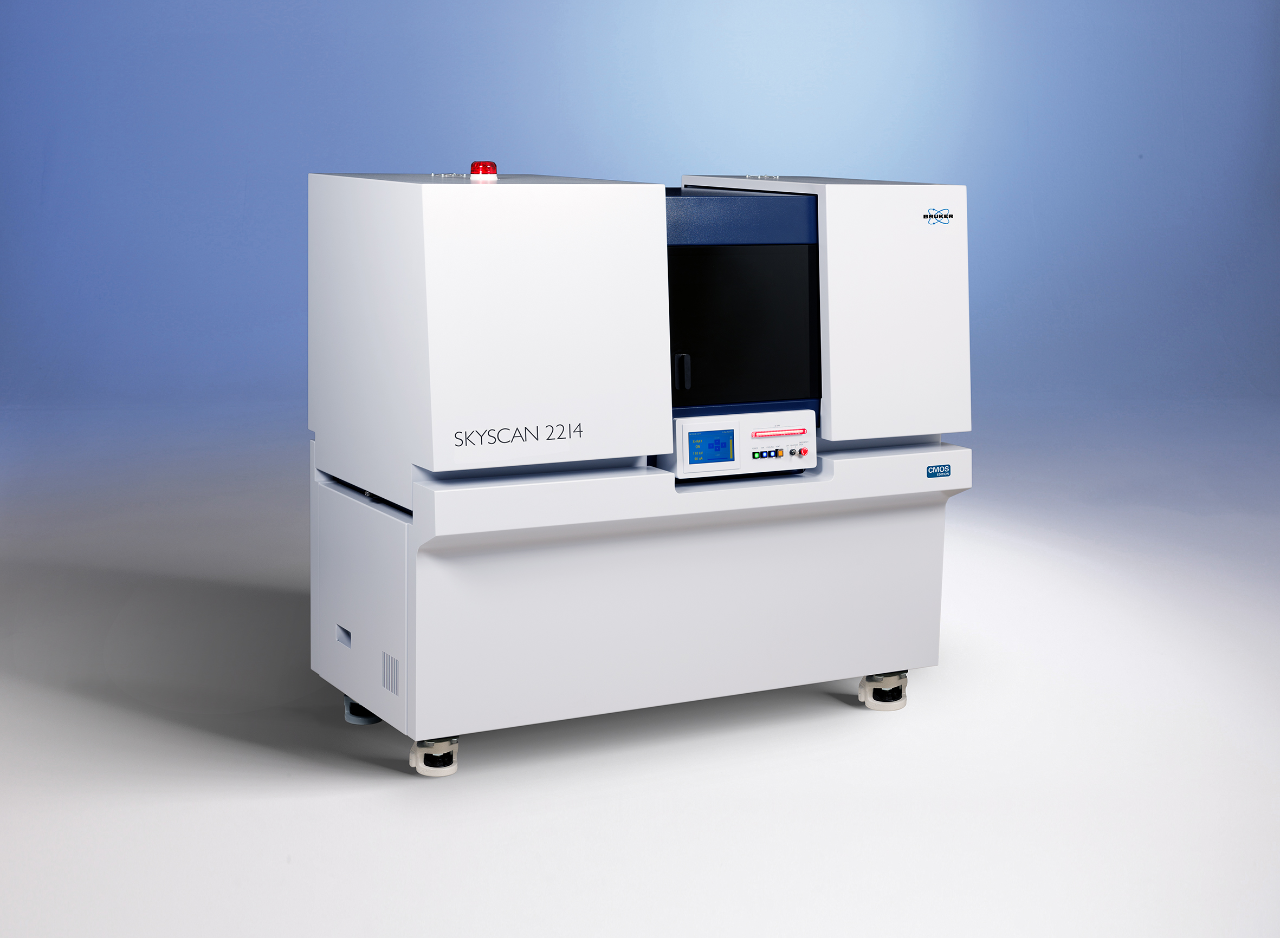

Specification | SKYSCAN 1275 | SKYSCAN 1272 CMOS | SKYSCAN 1273 | SKYSCAN 2214 CMOS |

Exterior dimensions (w x d x h, mm) | 1040 x 665 x 400 | 1160 x 520 x 330 | 1250 x 820 x 815 | 1800 x 950 x 1680 |

Weight (without optional electronics) | 170 kg | 150 kg | 400 kg | 1500 kg |

Source | 40-100 kV | 40-100 kV | 40-130 kV | 20-160 kV |

Detector | 3 Mp Flat Panel | 16 Mp CMOS | 6 Mp Flat Panel | 6 Mp Flat Panel 16 Mp large CMOS 16 Mp mid CMOS 15 Mp hi-res CMOS |

Max Sample Size (Diam, Height) | 96 mm, 120 mm | 75 mm, 80 mm | 300 mm, 500 mm | 300 mm, 400 mm |

Minimum Resolution (Voxel, Spatial) | <4 µm, <8 µm | <0.45 µm, <5 µm | <3 µm, <6 µm | 60 nm, <500 nm |

Measurement, Reconstruction and Analysis Software | Included | Included | Included | Included |

XRM Facility in Belgium and our Virtual Showroom

Visit the demo facilities in our headquarters in Karlsruhe (Germany) and Kontich (Belgium) or just take a virtual tour in our showrooms to see and learn more about our analytical solutions. If you have any questions, please do not hesitate to contact our team of experts from sales or customer support.

XRM

Bruker Belgium

Kartuizersweg 3B,

2550 Kontich, Belgium