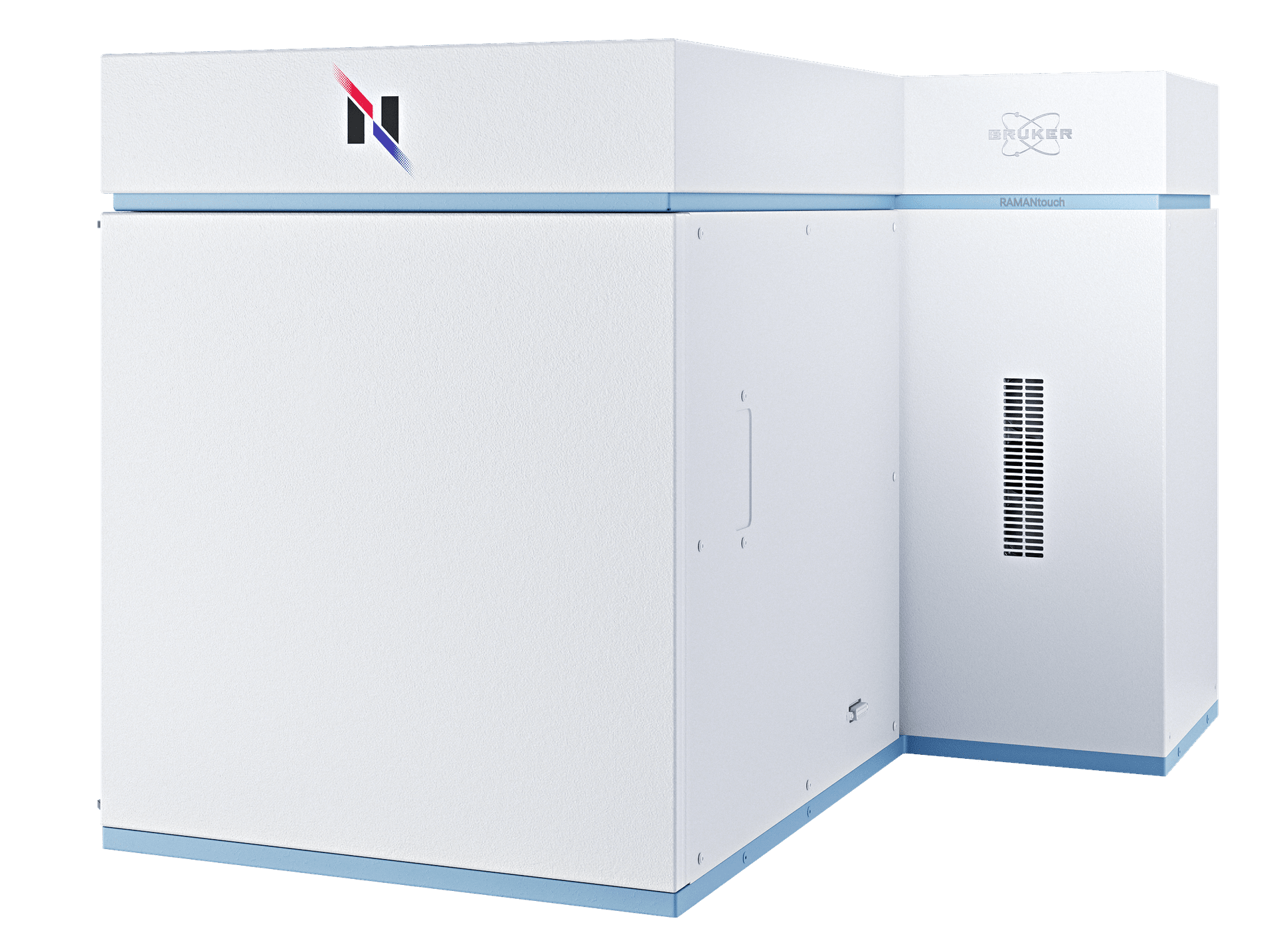

RAMANtouch

正真正銘

世界最速のラマンイメージング

卓越したイメージングスピードと精度をもつ共焦点ラマン顕微鏡

線状のレーザービーム照射と2次元CCD検出器により400スペクトルを一度に取得できるナノフォトンの技術。ガルバノミラーでレーザーを走査することで、RAMANtouchは高速かつ正確に数十万ピクセルからなるラマン画像を数分のうちに取得できます。EMCCDは必要ありません。

真のラマンイメージングがたどりついた答え

RAMANtouchは、従来のラマン顕微鏡とは全く新しいアプローチをとることで、不可能だったことを実現しています。スペクトルの質や空間分解能を落とすことなく最速のイメージングを実現しました。

RAMANtouhの特長:

- 超高速ラマンイメージング

- 高スペクトル分解能・高空間分解能

- 完全に自動化されたハードウェア

- 2D/3Dラマン画像の強力な解析ツール

- 自動較正・自動アライメント機能

stay tuned for more !

ガルバノミラーによるレーザー走査

ガルバノミラーを用いるという革新的な走査方法により、レーザービームを対物レンズ下の点を自由に走査できます。サンプルステージを動かさなくても大丈夫!精度とスピードの両方において、従来の「ステージ走査」方式にはるかに勝ります。

さらに、レーザービームは、視野の中心でも端でも、試料の観察面に対して垂直に入射します。これにより、次の測定モードでの測定が可能になります。

- ライン照明走査

高スペクトル分解能・高分解能の条件でも、最速・最高精度で試料表面を走査。 - ポイント照明走査

測定したいエリアに絞って測定し、各部分のスペクトルの実際の相違によって、測定範囲全体のイメージを素早く作成します。

- AreaFlash測定

ライン上のレーザーを視野全体にわたって高速走査することで、面の情報をくまなく拾い、平均スペクトルを取得します。これによって広範囲の超高速測定が可能になります。

どの測定モードでも最大のパフォーマンスを

ライン照明モード

- ライン照明による超高速ラマンイメージング

- 視野全体において均一かつひずみの無いライン照明

- EMCCD不要

ポイント照明モード

- 視野のエッジ部分でも焦点にレーザーをきれいに集光

- ステージ走査に比べて圧倒的に高速

- 10 nmに達する位置決め精度

優れた3Dラマンイメージング性能

共焦点光学系により、サンプルの内部のラマン分析を非破壊で実現します。これにより透明な試料の3Dラマンイメージを作成できます。RAMANtouchのライン照明と高精度ステージを用いることで、これまでにないスピードと品質で3Dラマン画像を測定し、試料の内部構造と成分分布を知る手掛かりを提供します。

測定事例動画:

- 透明な繊維の内部をラマンで検出

- 試料:芯鞘繊維(クラッド:ポリエチレン、コア:PET)

- 測定時間:20 - 30分

- 黄色い点: TiO2

最高のラマンイメージング分解能

XZ面内における深さ方向のラマンイメージングにより、多層膜のような試料を非破壊で分析できます。油浸対物レンズを使うことで、空間分解能が格段に向上し、300 nm程度の極薄層の検出も可能です。

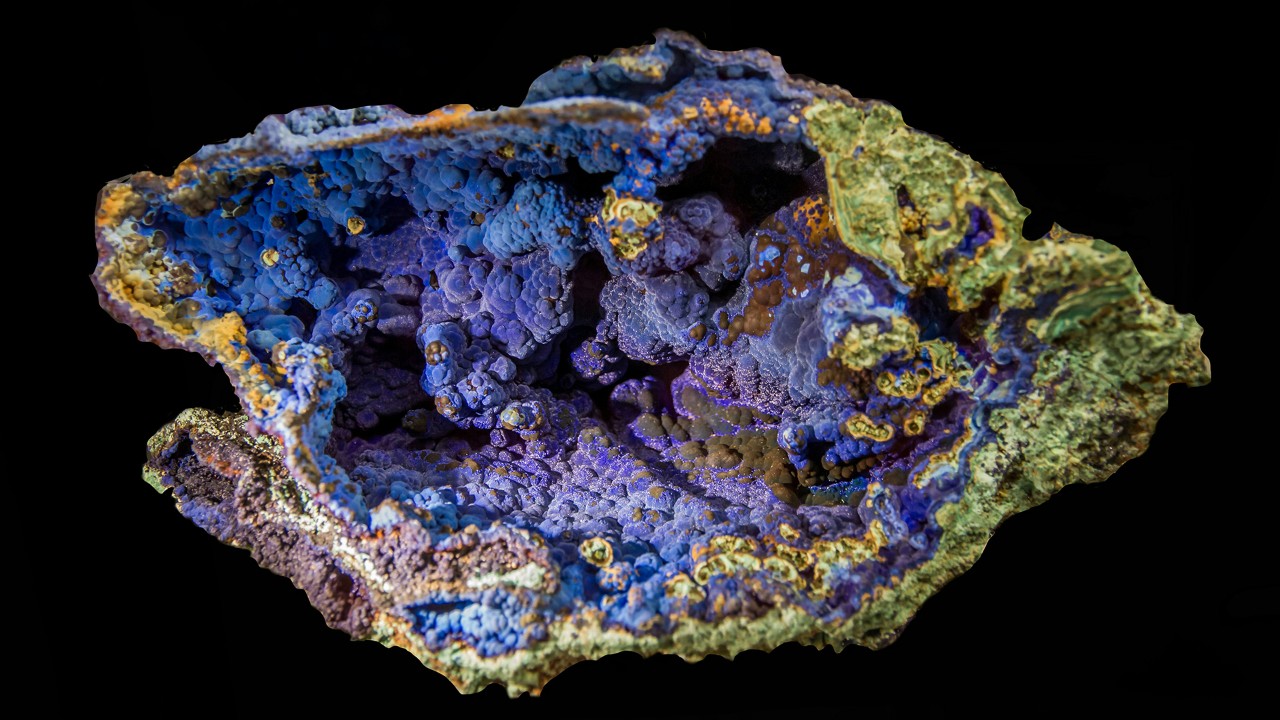

サブミクロン領域をのぞき見る

ラマン分光は、結晶多形のような、有機材料や無機材料の識別になくてはならない情報を提供してくれます。赤外分光と違い、ラマンにはサブミクロンの空間分解能や水を含む試料の分析も可能なことなどの強みがあります。

RAMANtouch Specifications

| 空間分解能 | X方向 500 nm, Y方向 350 nm, Z方向 1 µm | |

| 対物レンズ | 5x, 10x, 20x, 50x, 100x | |

| スペクトル分解能 | <0.9 cm-1 (回折格子による, 回折格子3つまで装着可) | |

| ステージ詳細 | 30 * 30 * 35 mm XYZ電動ステージ | |

| 較正 | 標準ランプ、標準試料を用いた自動較正 | |

| 調整機能 | 光軸の自動調整機能 | |

| レーザー安全基準 | インターロック機構を搭載したクラス1レーザー製品 |

When I first encountered a Bruker’s Nanophoton Raman microscope, which was installed for the first time at Analytical center in Chungbuk National University, I was very surprised by the various performances that are different from the previous Raman microscopy. In particular, I was very impressed the function of large-area mapping, which is a disadvantage of most of current Raman microscopy, was solved with the idea of line-illumination.

In our laboratory, Raman spectroscopy was utilized to quantify amino acids in renal cell cultures from an animal model of induced renal dysfunction and to study the distribution of drugs on the cell membrane surface. In addition, the content of illicitly distributed APIs-like compounds was determined by Raman imaging and a semi-quantification method was established.

In addition, the bio-samples that we are mainly researching in our laboratory are very difficult to find the optimum experimental conditions due to the control of the laser power, but the RAMANtouch model can not only adjust a very small power level, but also use the preview function to find the optimal conditions faster than any other Raman product. By using such a powerful Raman microscopy in our laboratory, we have published several number of related papers.

Professor Dr. Yong-Moon Lee, School of Pharmacy, Chungbuk National University, Korea.

The RAMANtouch microscope has made us rethink the limits of application of Raman imaging. The multiplexed acquisition approach brings a significant increase in speed, making it feasible to collect large Raman images instead of few measurement points. The system automation enables our users to utilize measurement time efficiently in overnight runs. This capability adds analytical depth to Raman characterization and facilitates a better understanding of complex research questions and enables big data exploration with machine learning tools.

At Synchrotron Soleil, we facilitate scientific progress by providing access to a high level research infrastructure. Beyond the beamline instrumentation, we also provide additional characterization tools such as offline Infrared or Raman microscopy.

Ferenc Borondis, Beamline Manager & Principal Beamline Scientist at Synchrotron SOLEI, Saint-Aubin, France.

Now, with the pioneering application of the modifed RAMANtouch system to the world’s first 8.5th generation display mass production line, we can achieve groundbreaking real-time defect analysis directly within the production process. By enabling component-level analysis of random defects—responsible for over 90% of yield-loss issues—this technology allows for precise defect identification, helping manufacturers not only trace defect origins and specify affected processes but also prevent these issues in real time.

In the high-stakes realm of display product mass production, advanced inspection technology has become essential for optimizing yield and ensuring top-tier quality control. As these technologies evolve, the need for faster, more precise process feedback has driven demand for real-time monitoring that goes beyond traditional inspection to include advanced measurement and in-depth analysis. Furthermore, In-line customized RAMANtouch’s proactive feedback capabilities offer unprecedented opportunities for continuous process improvement and accident prevention, marking a transformative step forward in display production technology.

Dr. Yong-Woon Lim, Metrology & Inspection Team, Samsung Display, Korea.

Frequently Asked Questions

- Why does RAMANtouch achieve high spatial resolution?

RAMANtouch is designed strictly according to optical principles and assembled by specialists in optical design, which ensures that every unit achieves stable and reproducible performance. Its compact mechanical structure also minimizes the likelihood of misalignment caused by environmental changes. - Do I need to adjust the optics when switching lasers?

No manual adjustments are necessary. When a laser is switched, the required optical adjustments are performed automatically, and the change can be carried out with a single click. - Do I need to adjust the optics when switching diffraction gratings?

No. Just like laser switching, the instrument automatically adjusts the optics after the grating is changed, and the user does not need to perform any manual alignment. - Why are line illumination and laser beam scanning used?

These methods reflect Nanophoton’s origins in laser microscopy. Laser beam scanning eliminates the need to adjust measurement positions by moving a motorized stage and avoids issues such as vibration or sample displacement introduced by stage movement. The proprietary line illumination method enables the acquisition of 400 Raman spectra in the X-direction with a single irradiation, allowing high-speed Raman imaging. - How is illumination unevenness in line illumination addressed?

Although uneven intensity between the center and edges of the line is a common concern in line-illumination systems, RAMANtouch significantly reduces this issue using a proprietary technology covered by U.S. Patent US7561265. - Can high-power laser irradiation damage samples?

RAMANtouch includes an ND filter that provides nearly stepless control of laser power across 256 levels. This allows high power to be used efficiently for samples that tolerate it, while also enabling safe measurement of heat-sensitive samples by reducing the power appropriately. - How large is the field of view?

The field of view depends on the objective lens. With a 20× objective, the observation area is about 400 µm × 600 µm and the maximum imaging range is approximately 400 µm square. With a 100× objective, the observation area is roughly 80 µm × 100 µm and the maximum imaging range is about 80 µm square.