Hysitron PI Envision SEM PicoIndenter

Hysitron PI Envision SEM PicoIndenter

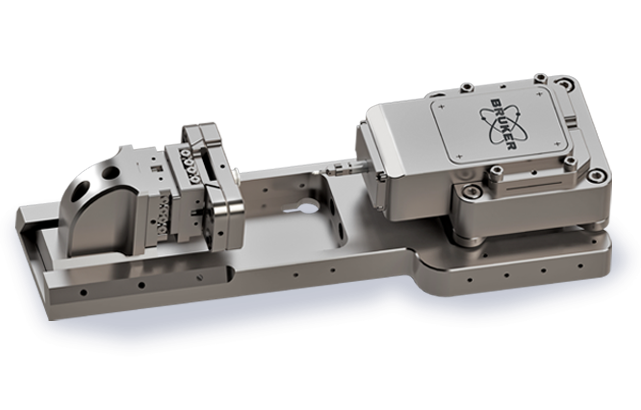

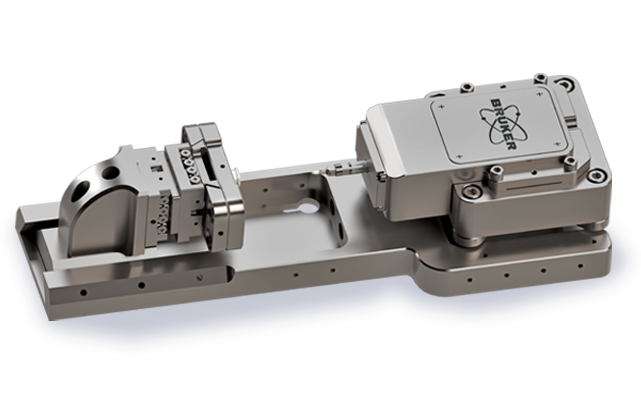

Hysitron PI Envision is a leading-edge nanomechanical testing instrument designed for in-situ operation in standard SEMs, FIB-SEMs, small-chamber SEMs, and even synchrotron beamlines. Its sub-nanometer displacement and sub-micronewton resolution make it suitable for analyzing materials from soft polymers to high strength metals and alloys. This modular platform is highly upgradable, supporting a powerful suite of techniques, including nanoindentation, property mapping, and high-temperature testing up to 800°C. PI Envision delivers best-in-class versatility, precision, and value ideal for multi-user facilities and budget-conscious laboratories.

Affordable, Reliable, Upgradable, and Easy to Use

Hysitron PI Envision is an easily upgradable platform that offers a powerful suite of in-situ testing techniques. It is an indispensable, affordable, and reliable SEM accessory for nanomechanical and nanotribological testing.

PI Envision delivers:

- Intrinsic displacement control, intrinsic load control, and open loop nanomechanical testing for a wide range of materials

- Advanced upgrades for performing nanotribology, property mapping, and high-temperature testing to 800°C

- Encoded stage control and 78 kHz feedback rate for fast, repeatable results from indentation, compression, tension, or fatigue testing

Essential Ease-of-Use Features

PI Envision is designed to streamline your work, with:

- An encoded stage to ensure precise sample positioning

- Positioning travel of 12x12 mm to provide easy sample access

- No-stitch property mapping for >1 mm x >1 mm area

- Two sample mounts to reduce manual sample changes

Configure Your System

All PI Envision configurations deliver intrinsic displacement actuation and control with sub-nanometer resolution, feedback rate of 78 kHz, and data acquisition up to 39 kHz.

The base system supports up to 10 mN force and sub-nanometer to 5 µm displacement range, making it an excellent choice for routine indentation, compression, and tensile testing of low-hardness to medium-hardness materials.

An optional xR transducer extends the maximum load to 250 mN and displacement range up to 100 µm, making it ideal for high-hardness materials and nanotribology.

Additional testing capabilities include:

- Push-to-Pull (PTP) Tensile Testing — Uniquely simplifies tensile testing of nanostructures such as nanotubes, nanofibers, nanowires, and thin films

- Electrical PTP Tensile Testing — Enhances PTP testing with integrated four-point electrical measurements to study electromechanical coupling

- Electrical Characterization — Monitors changes in electrical properties during mechanical deformation; applicable to piezoelectric and other functional materials

- nanoDynamic Testing — Applies oscillatory forces to continuously evaluate viscoelastic and fatigue properties at room and elevated temperatures

Key features and specs of PI Envision and PI 89

| PI Envision | PI 89 | |

| Max transducer force (mN) | 250 mN | 3500 mN |

|---|---|---|

| Max transducer displacement | 100 µm | 150 µm |

| Stage travel (X, Y and Z), Y = indentation direction | 12, 16, 12 | 26, 29, 12 |

| Sample position (XY) | 12 mm x 12 mm | 12 mm x 26 mm |

| Multi-Sample mounting compatibility | 2 samples | 6 samples |

| Property mapping area | 12 mm x 12 mm | 12 mm x 26 mm |

| High temperature | 800°C | 800°C and 1000°C |

| Rotation and tilt stage (5 deg of freedom for in-situ correlative characterization) | No | Yes |

| Cryogenic temp | Not available | -130°C (possible to reach well below -130°C depending on the sample size and SEM chamber) |

| nanoTribology | Yes | Yes |

| Push-to-Pull and Electrical; Push-to-Pull | Yes | Yes |

| NanoDynamic, Fatigue | Yes (room temperature and high temperature) | Yes (room temperature, high temperature and cryogenic temperature) |

| Electrical characterization | Yes | Yes |

| DOWNLOAD THE BROCHURE TO SEE FULL SYSTEM SPECIFICATIONS |

Analyze Your Data

Hysitron nanomechanical test instruments come standard with Tribo iQ, Bruker’s complete data processing, graphic, and reporting solution. Tribo iQ encompasses a suite of technique-specific software applications that simplify and streamline the experiment-analysis loop.

Contact Us About the Hysitron PI Envision SEM PicoIndenter

Ask us a question, request more information, or get in touch with a Bruker sales representative.