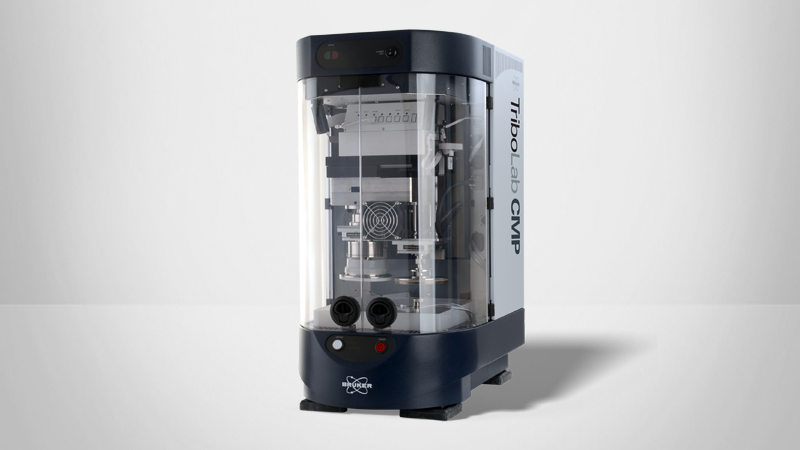

摩擦磨损测试仪和机械测试仪

测量摩擦、磨损和力学性能,从而了解材料、涂层及润滑剂如何在严苛的环境下工作

摩擦磨损和机械性能测试仪

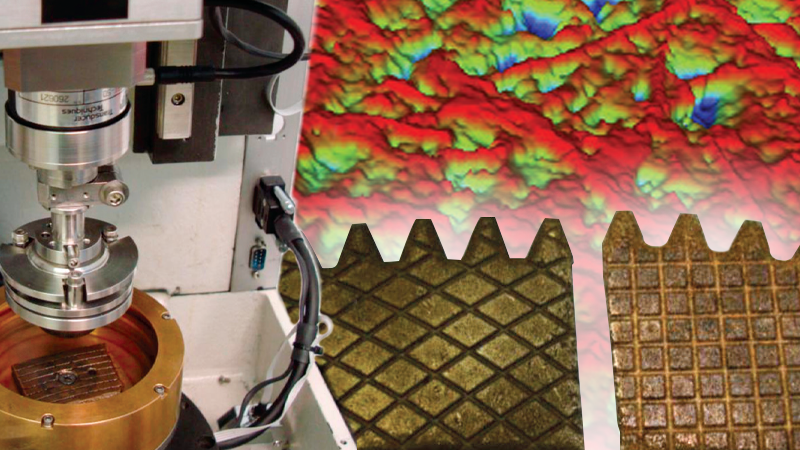

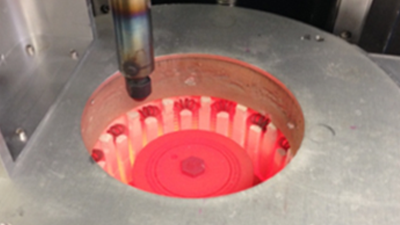

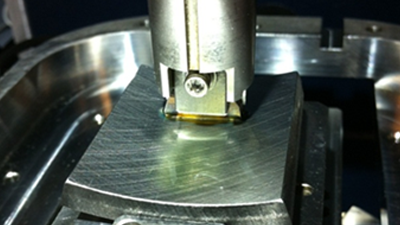

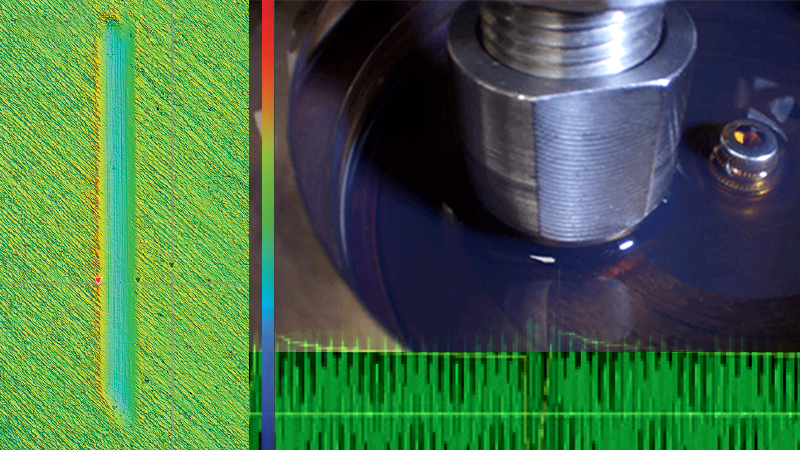

对于材料以及如何改变材料来影响强度、完整性或耐久性的研究,是几乎所有行业的产品设计和产品升级必不可少的一部分。布鲁克的力学测试仪和摩擦磨损测试仪可提供用于研究摩擦学——摩擦、磨损、载荷、硬度和润滑的全面和通用的方法。工程师们经常通过测量摩擦、磨损和材料力学性能来了解材料、涂层和润滑剂如何经受从重工业到半导体、从汽车到生物医学等各种应用的严酷考验。

View key publications with Bruker Tribometers and Mechanical Testers

- Zahmatkesh, S., & Rizvi, R. (2025). Evaluating Surface Texturing Technologies of Rubber Composites on Ice Using a Novel High-Velocity Tribotest Method. Tribology International, 110538.

- Li, M., Bai, Y., Ou, Y., Ren, X., & Qian, C. (2025). Study on friction and wear properties of nickel-based alloys under different working conditions. Heliyon, 11(2).

- Soranansri, P., Dubois, A., Moreau, P., Funazuka, T., Dohda, K., & Dubar, L. (2025). Tribological performance of AlCrN and TiAlN coatings in aluminum forming process at high temperature. Solid State Phenomena, 370, 89-97.

- Joukar, A., Karnik, S., Noori-Dokht, H., Younesi, S., Trippel, S. B., & Wagner, D. R. (2025). Mechanical Wear of Degraded Articular Cartilage. Annals of Biomedical Engineering, 1-10.

- Jin, B., Du, N., Meng, T., Chen, G., Cao, Y., Zhang, H., ... & Luo, J. (2025). High contact stress phase transition structural superlubricity. Carbon, 120306.

- Kalácska, Á., Parmentier, V., De Baets, P., & Kalácska, G. (2025). Wear investigation of PTFE, PEEK and UHMWPE-based reciprocating shaft seal materials with lunar/Martian regolith simulants. Wear, 205791.

- Xie, Y. F., Lu, X., Wang, J., Wang, X. Z., Liu, S., Zhang, Y., ... & Wang, F. (2025). Superior tribocorrosion resistance of Mg metal matrix composite by self-sealing PEO coating. Corrosion Science, 112938.

- Nečas, D., Gelnar, A., Rothammer, B., Marian, M., Ranuša, M., Wartzack, S., ... & Hartl, M. (2025). Frictional Behaviour and Surface Topography Evolution of DLC‐Coated Biomedical Alloys. Biosurface and Biotribology, 11(1), e70004.

- Jahromi, H. S., Mohammadi, H., Kode, S. K., Ellis, J. D., & Menon, D. R. (2025). Effect of Laser Power and Diamond Tool Parameters for Micro Laser-Assisted Ductile Mode Material Removal on Fused Silica. Journal of Micro and Nano Science and Engineering, 13(1).

- Chen, Y., Peng, K., Li, X., Sun, L., Su, T., Zhang, W., ... & Zhou, M. (2025). Lubricating and Conductive Properties of Modified Graphene/Silver Nanoparticles Under Current-Carrying Friction Conditions. Lubricants, 13(1), 38.

- Su, T., Peng, K., Zhang, D., Sun, L., Chen, Y., Yu, Y., & Zhou, M. (2025). Synergistic Lubrication and Anti-Corrosion Effects of Benzotriazole and Ionic Liquid Under Current-Carrying Friction. Lubricants, 13(2), 77.

- Liao, X., Bai, M. H., Liu, Y. W., Wei, Y. Q., Wang, J. Y., Wang, Z. G., ... & Li, K. (2025). Mitigating intubation stress, mucosa injury, and inflammatory response in nasogastric tube intubation via suppression of the NF-κB signaling pathway by engineering a hydration lubrication coating. Journal of Materials Chemistry B.

- Wang, W., Deng, Z., Chen, Z., Yuan, L., Xiang, J., Dai, L., & Tang, K. (2025). Laser-induced and Conformal liquid-silicone Casting of oxalis-inspired graphene-based Piezoresistive Pressure Sensors. Journal of Bionic Engineering, 1-14.

- Li, J., & Chen, M. (2025). Instance segmentation of on-line wear debris using deep convolutional neural network with transfer learning. Industrial Lubrication and Tribology, 77(2), 211-218.

- Zong, Y., Zhao, Y., He, W., Jia, Y., & Le, H. (2025). Research on the anti-frost performance of hydrophobic TiN-polymer composite coating on aluminum alloy surface. Composites Communications, 53, 102186.

- Bahatibieke, A., Zhao, J., Fan, D., Zhou, Z., Li, J., Wang, X., ... & Zheng, Y. (2025). Sea-Island Micelle Structured Hydrogel Scaffold: A Dual-Action Approach to Combat Cartilage Damage under RA Conditions. ACS Applied Materials & Interfaces.

- Chai, J., Ru, Y., Jia, Y., Yang, Y., Zhang, H., Chen, L., ... & Liu, M. (2025). Friction Memory Ionogels With Hysteretic Sticky‐Slippery Transition via Thermolocking the Metastable state. Advanced Materials, 37(13), 2416250.

- Zhang, J., Hu, W., & Li, J. (2025). Enhanced Tribological Performance of Melamine Long-Chain Alcohol Esters in High-Temperature Boundary Lubrication. Lubricants, 13(3), 114.

- Zhang, Y., Yan, H., Li, S., & Zheng, Z. (2025). Effect of induction heating composite shot peening on fatigue crack growth behavior, wear performance of 20CrMnTi gear steel. Surface Topography: Metrology and Properties.

- Wei, G., Wang, G., Zhong, L., Wang, Y., He, X., Li, M., ... & Liao, W. (2025). Influence of Groove Texture Parameters on the Friction Performance of Roller Bit Floating Sleeve Bearings. Journal of Tribology, 1-22.

- Elkington, R. J., Armitage, J. L., Khan, T., & Bryant, M. G. (2024). Sticky feet: A tribological study of climbing shoe rubber. Sports Engineering, 27(2), 30.

- Soranansri, P., Dubois, A., Moreau, P., Funazuka, T., Dohda, K., & Dubar, L. (2024). Identification of coulomb and constant shear frictions in hot aluminum forming by using warm and hot upsetting sliding test. International Journal of Material Forming, 17(6), 55.

- Zhang, H., Hu, X., Liu, Y., Zhu, B., & Zhang, Y. (2024, December). Research on high temperature friction performance of carbon fiber composite materials. In 7th International Conference on Advanced High Strength Steel and Press Hardening (ICHSU 2024) (pp. 382-389). Atlantis Press.

- Evans, T., & Palgrave, R. (2024). An investigative study on different magnetic ionic liquids to be used as a lubricant and sealant in a vacuum pump. Tribology and Materials, 3(1), 24-34.

- Wang, Y., Wang, Y., Wang, T., Luo, Z., & Rao, S. (2024). Influence of Heat Treatment on the Key Service Properties of Built-Up Welding Layer on Pinch Rollers. Journal of Failure Analysis and Prevention, 24(5), 2517-2529.

- Ren, B., Xia, Y., Chen, Y., Su, Y., Lou, J., Zhang, C., ... & Dai, M. (2024). Effect of C2H2 flow rate on microstructure, properties, and application in micro-drilling of aC: H films deposited by PECVD. Journal of Materials Research and Technology, 29, 1194-1205.

- Wei, R., Deng, J., Guo, X., Yang, Y., Miao, J., Liu, A., ... & Wang, R. (2024). Construction of zwitterionic coatings with lubricating and antiadhesive properties for invisible aligner applications. Macromolecular Rapid Communications, 2400234.

- Hu, L., Yu, W., Liu, J., Yang, Y., Hao, J., & Xu, L. (2024). Highly lubricative, self-healing, chemically degradable, anti-flaming and anti-irradiating magnetic gels simply prepared from binary mixtures of Fe 3 O 4 nanoparticles and water. Journal of Materials Chemistry A, 12(13), 7549-7563.

- Liao, M., Cammarata, A., & Polcar, T. (2024). Charge-induced ultralow friction between graphite and atomically flat surfaces. Carbon, 223, 119036.

- Chen, Y., Li, H., Su, F., Ma, G., Li, Q., Sun, J., & Lin, S. (2024). Friction and wear behavior of molybdenum-disulfide doped hydrogen-free diamond-like carbon films sliding against Al2O3 balls at elevated temperature. Wear, 544, 205296.

- Tang, G., Sun, S., Yang, J., Pan, Y., Liu, Z., & Liang, Z. (2024). Fabrication and tribological properties of WC-reinforced Inconel X-750 alloy at elevated temperature. Journal of Manufacturing Processes, 131, 1321-1333.

- Evans, T., & Palgrave, R. (2024). An investigative study on different magnetic ionic liquids to be used as a lubricant and sealant in a vacuum pump. Tribology and Materials, 3(1), 24-34.

- Ren, B., Su, Y., Lou, J., Zhang, C., Tang, P., Lin, S., ... & Zhou, K. (2024). PECVD technology deposition of high hardness aC: H films on micro-drill surfaces: Substrate bias voltage effects. Journal of Manufacturing Processes, 124, 385-398.

- Shi, H., Li, H., Guo, Z., Lu, H., Wang, J., & Li, J. (2024). GNBoost-Based Ensemble Machine Learning for Predicting Tribological Properties of Liquid-Crystal Lubricants. Langmuir, 40(20), 10705-10717.

- Men, S., Yang, P., Gyawali, G., Yang, Y., Li, D., Nouri, M., & Zhang, S. (2024). Insight into the corrosion behaviors and mechanism of arc discharge plasma nitrided H13 steel in molten Al-Si. Applied Surface Science, 670, 160584.

- Haider, S. B., Heon, E., Neveau, M., Chen, P., Houston, A., Rios, O., & Lass, E. A. (2024). Castable eutectic Ni–Ce high temperature alloys strengthened by γ/γʹ microstructure. Journal of Materials Research and Technology, 28, 3943-3950.

- Ren, Y., Liu, X., Chang, C., & Zhang, S. (2024). Tribological performance of c-BN/TiC-enhanced NiCrBSi coatings prepared by high-velocity oxy-fuel spraying tested from room temperature to 1000° C. Ceramics International, 50(13), 22947-22959.

- Tian, H., Cui, Z., Zhang, X., & Zhang, X. (2024). Effect of cathodic potential and corrosion product on tribocorrosion behavior of S420 steel in the marine environment. Materials Today Communications, 38, 108372.

- Liu, Q., Chen, X., Liu, K., Cristino, V. A., Lo, K. H., Xie, Z., & Kwok, C. T. (2024). Friction stir processing of M2 and D2 tool steels for improving hardness, wear and corrosion resistances. Surface and Coatings Technology, 481, 130609.

- Yurchenko, E. V., Ghilețchii, G. V., Vatavu, S. A., Petrenko, V. I., Harea, D., Bubulinca, C., & Dikusar, A. I. (2024). Composition, Structure, and Wear Resistance of Surface Nanostructures Obtained by Electric Spark Alloying of 65G Steel. Surface Engineering and Applied Electrochemistry, 60(2), 194-203.

- Xie, J., Li, P., Qian, Z., & Qian, Z. (2024). Wear simulation of pin-on-disc sliding wear test. In Journal of Physics: Conference Series (Vol. 2862, No. 1, p. 012040). IOP Publishing.

- Qi, Y., Gao, J., Liang, W., Miao, Q., Jia, F., Chang, X., & Lin, H. (2024). A comparison of the tribological properties of SiC coatings prepared via atmospheric plasma spraying and chemical vapor deposition for carbon/carbon composites. Lubricants, 12(9), 301.

- Kladovasilakis, N., Pechlivani, E. M., Sfampa, I. K., Tsongas, K., Korlos, A., David, C., & Tzovaras, D. (2024). Metal 3D-printed bioinspired lattice elevator braking pads for enhanced dynamic friction performance. Materials, 17(11), 2765.

- Elkington, R. J., Hall, R. M., Beadling, A. R., Pandit, H., & Bryant, M. G. (2024). Engineering tribological rehydration of cartilage interfaces: Assessment of potential polyelectrolyte mechanisms. Tribology International, 197, 109822.

- Buyuksungur, S., Parau, A. C., Dinu, M., Pana, I., Vitelaru, C., Schmidt, J., ... & Hasirci, N. (2024). Variations of chemical, physical, mechanical properties, and biological and antimicrobial effectiveness of Ti alloys by coating with CaP doped with different amounts of Zn via micro-arc oxidation (MAO) technique. Ceramics International, 50(19), 37096-37110.

- Zheng, X., Zheng, K., Jia, W., Qu, S., Yu, S., Zhou, B., ... & Gao, J. (2024). Plasma surface alloyed Ta diffusion layer and Ta coating on Ti6Al4V alloy: Mechanical and wear properties. Journal of Applied Physics, 136(2).

- Siahpour, P., Omar, S. M. T., Griffin, D., Amegadzie, M. Y., Tieu, A., Donaldson, I. W., & Plucknett, K. P. (2024). Evaluating surface mechanical properties and wear resistance of Ti–6Al–4V alloy subjected to ultrasonic pulsed waterjet peening. Wear, 550, 205400.

- Zhang, C., He, Y., Zhang, S., Li, C., Gou, R., Zhang, J., & Sun, D. (2024). A novel siloxene@ MoS2 heterostructure for improving the wear and corrosion resistance performance of epoxy coatings. Colloids and Surfaces A: Physicochemical and Engineering Aspects, 700, 134785.

- Chen, X., Sun, S., Wang, D., Li, J., Yang, C., Jiang, Y., & Chang, X. (2024). Construction of robust superhydrophobic surfaces with an'armour'structure on the low-temperature steels by picosecond laser processing. Tribology International, 195, 109637.

- Elkington, R. J., Hall, R. M., Beadling, A. R., Pandit, H., & Bryant, M. G. (2024). Brushing up on cartilage lubrication: Polyelectrolyte-enhanced tribological rehydration. Langmuir, 40(20), 10648-10662.

- Ozdemir, I., Bulbul, B., Kiracbedel, U., Grund, T., & Lampke, T. (2024). Wear Performance Evaluation of Polymer Overlays on Engine Bearings. Materials, 17(15), 3802.

- Escherová, J., Krbata, M., Kohutiar, M., Barényi, I., Chochlíková, H., Eckert, M., ... & Dubcová, P. (2024). The Influence of Q & T Heat Treatment on the Change of Tribological Properties of Powder Tool Steels ASP2017, ASP2055 and Their Comparison with Steel X153CrMoV12. Materials, 17(5), 974.

- Biedma, Á., Sánchez, G., de Nicolás, M., Bertalan, C., Useldinger, R., Llanes, L., & Gordo, E. (2024). A Comparative Study on the Wear Performance and High-Temperature Oxidation of Co-Free Cermets and Hardmetals. Materials, 17(14), 3615.

- Yin, Y., Shi, P., Zhang, S., Qing, T., Zhou, N., Qian, L., & Chen, L. Deeply Understanding Lubrication Failure of Steel Ball Against Oil-Impregnated Porous Polyimide in Double-Contact Friction with Rolling‑Sliding Motion. Available at SSRN 4692446.

- Park, J. E., Je, H., Kim, C. R., Park, S., Yu, Y., Cho, W., ... & Wie, J. J. (2024). Programming Anisotropic Functionality of 3D Microdenticles by Staggered‐Overlapped and Multilayered Microarchitectures. Advanced Materials, 36(7), 2309518.

- Yun, S., Um, Y., Park, H. W., & Kim, S. (2024). Static friction of magneto-rheological elastomer pads in wall-climbing robots. CIRP Annals, 73(1), 441-444.

- Wang, L., Ta, T., & Tieu, K. A. Tribological Roles of Glass‐Based Lubricants in Hot Rolling of Steel. steel research international, 2400107.

- Devenport, T. M., Lu, P., Rolfe, B. F., Pereira, M. P., & Griffin, J. M. (2024, October). Acoustic Emission Characteristics of Galling Behavior from Dry Scratch Tests at Slow Sliding Speed. In Acoustics (Vol. 6, No. 4, pp. 834-869). MDPI.

- Gong, L., Zhang, Z., Yu, W., Zeng, J., Cao, J., Fan, B., ... & Zhang, C. (2024). Ultra‐Durable Polysilicon Based Tribovoltaic Nanogenerators for Bearing In Situ Rotational Speed Sensing. Small, 20(50), 2405992.

支持

我们能提供哪些支持?

布鲁克致力于为客户解决实际应用问题。我们不断开发新的测试技术,并帮助客户选择最合适的系统与配件。我们通过培训或者延保等方式,与客户保持长久的合作关系。

我们拥有专业的服务团队,支持工程师、应用科学家和专家团队将通过系统服务,功能升级,应用拓展和技术培训等多种方式帮助您最大化的发挥设备的效能。