トライボロジー評価機・CMPプロセス/材料特性評価機

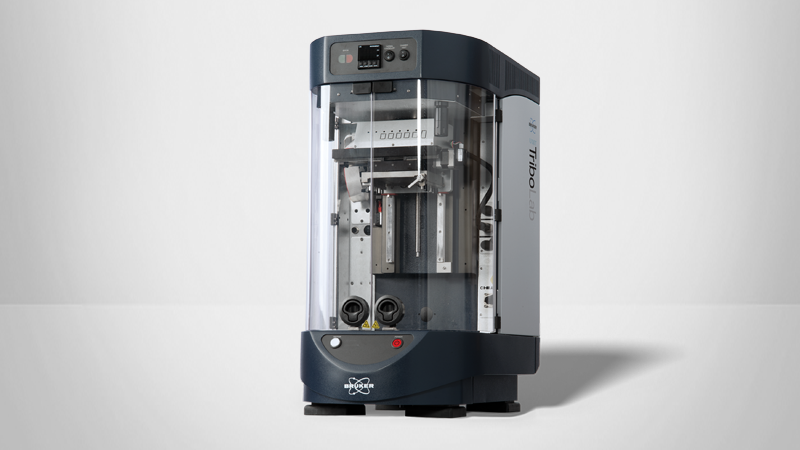

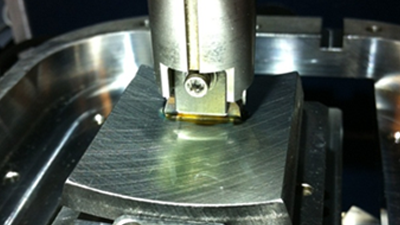

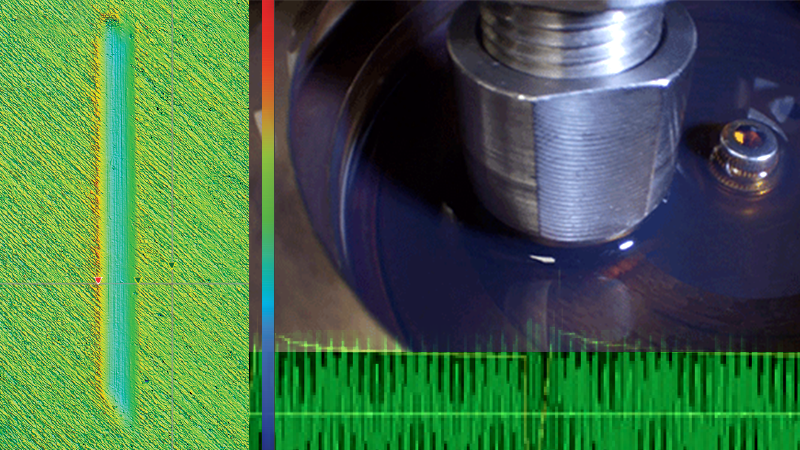

トライボメータとメカニカルテスター

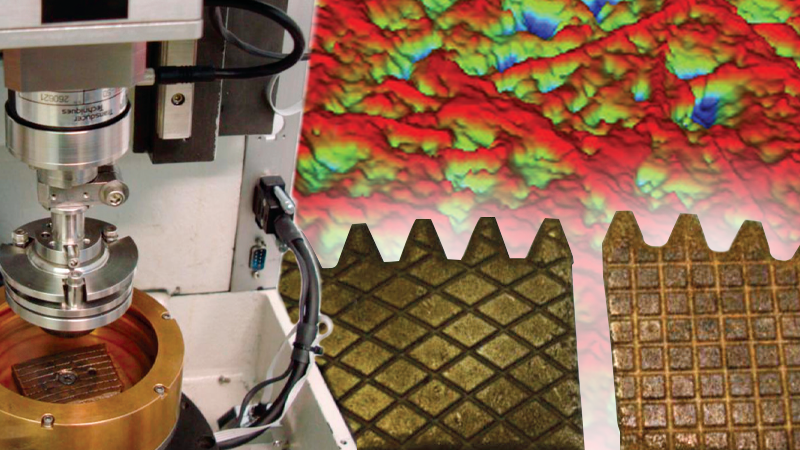

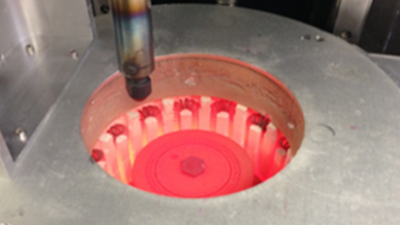

材料研究と、強度、無欠陥性、耐久性を向上させるためにどのように材料を改質できるかは、ほぼすべての産業の製品の設計および改善において重要な部分です。ブルカーの機械試験ソリューションは、—摩擦、摩耗、荷重、硬度、および潤滑の摩擦学を調査するための最も包括的かつ多様な方法を提供します。摩擦、摩耗、および材料の機械特性の計測は、材料、コーティング、および潤滑剤が、重工業から半導体、自動車からバイオ医療にわたる各種用途での過酷さにどの程度耐えられるかを理解する方法の1つです。

トライボロジー評価機・CMPプロセス評価機ウェビナー

当社の Webinar は、ベスト プラクティスをカバーし、新製品を導入し、難しい質問に対する迅速なソリューションを提供し、新しいアプリケーション、モード、またはテクニックのアイデアを提供します。

View key publications with Bruker Tribometers and Mechanical Testers

- Zahmatkesh, S., & Rizvi, R. (2025). Evaluating Surface Texturing Technologies of Rubber Composites on Ice Using a Novel High-Velocity Tribotest Method. Tribology International, 110538.

- Li, M., Bai, Y., Ou, Y., Ren, X., & Qian, C. (2025). Study on friction and wear properties of nickel-based alloys under different working conditions. Heliyon, 11(2).

- Soranansri, P., Dubois, A., Moreau, P., Funazuka, T., Dohda, K., & Dubar, L. (2025). Tribological performance of AlCrN and TiAlN coatings in aluminum forming process at high temperature. Solid State Phenomena, 370, 89-97.

- Joukar, A., Karnik, S., Noori-Dokht, H., Younesi, S., Trippel, S. B., & Wagner, D. R. (2025). Mechanical Wear of Degraded Articular Cartilage. Annals of Biomedical Engineering, 1-10.

- Jin, B., Du, N., Meng, T., Chen, G., Cao, Y., Zhang, H., ... & Luo, J. (2025). High contact stress phase transition structural superlubricity. Carbon, 120306.

- Kalácska, Á., Parmentier, V., De Baets, P., & Kalácska, G. (2025). Wear investigation of PTFE, PEEK and UHMWPE-based reciprocating shaft seal materials with lunar/Martian regolith simulants. Wear, 205791.

- Xie, Y. F., Lu, X., Wang, J., Wang, X. Z., Liu, S., Zhang, Y., ... & Wang, F. (2025). Superior tribocorrosion resistance of Mg metal matrix composite by self-sealing PEO coating. Corrosion Science, 112938.

- Nečas, D., Gelnar, A., Rothammer, B., Marian, M., Ranuša, M., Wartzack, S., ... & Hartl, M. (2025). Frictional Behaviour and Surface Topography Evolution of DLC‐Coated Biomedical Alloys. Biosurface and Biotribology, 11(1), e70004.

- Jahromi, H. S., Mohammadi, H., Kode, S. K., Ellis, J. D., & Menon, D. R. (2025). Effect of Laser Power and Diamond Tool Parameters for Micro Laser-Assisted Ductile Mode Material Removal on Fused Silica. Journal of Micro and Nano Science and Engineering, 13(1).

- Chen, Y., Peng, K., Li, X., Sun, L., Su, T., Zhang, W., ... & Zhou, M. (2025). Lubricating and Conductive Properties of Modified Graphene/Silver Nanoparticles Under Current-Carrying Friction Conditions. Lubricants, 13(1), 38.

- Su, T., Peng, K., Zhang, D., Sun, L., Chen, Y., Yu, Y., & Zhou, M. (2025). Synergistic Lubrication and Anti-Corrosion Effects of Benzotriazole and Ionic Liquid Under Current-Carrying Friction. Lubricants, 13(2), 77.

- Liao, X., Bai, M. H., Liu, Y. W., Wei, Y. Q., Wang, J. Y., Wang, Z. G., ... & Li, K. (2025). Mitigating intubation stress, mucosa injury, and inflammatory response in nasogastric tube intubation via suppression of the NF-κB signaling pathway by engineering a hydration lubrication coating. Journal of Materials Chemistry B.

- Wang, W., Deng, Z., Chen, Z., Yuan, L., Xiang, J., Dai, L., & Tang, K. (2025). Laser-induced and Conformal liquid-silicone Casting of oxalis-inspired graphene-based Piezoresistive Pressure Sensors. Journal of Bionic Engineering, 1-14.

- Li, J., & Chen, M. (2025). Instance segmentation of on-line wear debris using deep convolutional neural network with transfer learning. Industrial Lubrication and Tribology, 77(2), 211-218.

- Zong, Y., Zhao, Y., He, W., Jia, Y., & Le, H. (2025). Research on the anti-frost performance of hydrophobic TiN-polymer composite coating on aluminum alloy surface. Composites Communications, 53, 102186.

- Bahatibieke, A., Zhao, J., Fan, D., Zhou, Z., Li, J., Wang, X., ... & Zheng, Y. (2025). Sea-Island Micelle Structured Hydrogel Scaffold: A Dual-Action Approach to Combat Cartilage Damage under RA Conditions. ACS Applied Materials & Interfaces.

- Chai, J., Ru, Y., Jia, Y., Yang, Y., Zhang, H., Chen, L., ... & Liu, M. (2025). Friction Memory Ionogels With Hysteretic Sticky‐Slippery Transition via Thermolocking the Metastable state. Advanced Materials, 37(13), 2416250.

- Zhang, J., Hu, W., & Li, J. (2025). Enhanced Tribological Performance of Melamine Long-Chain Alcohol Esters in High-Temperature Boundary Lubrication. Lubricants, 13(3), 114.

- Zhang, Y., Yan, H., Li, S., & Zheng, Z. (2025). Effect of induction heating composite shot peening on fatigue crack growth behavior, wear performance of 20CrMnTi gear steel. Surface Topography: Metrology and Properties.

- Wei, G., Wang, G., Zhong, L., Wang, Y., He, X., Li, M., ... & Liao, W. (2025). Influence of Groove Texture Parameters on the Friction Performance of Roller Bit Floating Sleeve Bearings. Journal of Tribology, 1-22.

- Elkington, R. J., Armitage, J. L., Khan, T., & Bryant, M. G. (2024). Sticky feet: A tribological study of climbing shoe rubber. Sports Engineering, 27(2), 30.

- Soranansri, P., Dubois, A., Moreau, P., Funazuka, T., Dohda, K., & Dubar, L. (2024). Identification of coulomb and constant shear frictions in hot aluminum forming by using warm and hot upsetting sliding test. International Journal of Material Forming, 17(6), 55.

- Zhang, H., Hu, X., Liu, Y., Zhu, B., & Zhang, Y. (2024, December). Research on high temperature friction performance of carbon fiber composite materials. In 7th International Conference on Advanced High Strength Steel and Press Hardening (ICHSU 2024) (pp. 382-389). Atlantis Press.

- Evans, T., & Palgrave, R. (2024). An investigative study on different magnetic ionic liquids to be used as a lubricant and sealant in a vacuum pump. Tribology and Materials, 3(1), 24-34.

- Wang, Y., Wang, Y., Wang, T., Luo, Z., & Rao, S. (2024). Influence of Heat Treatment on the Key Service Properties of Built-Up Welding Layer on Pinch Rollers. Journal of Failure Analysis and Prevention, 24(5), 2517-2529.

- Ren, B., Xia, Y., Chen, Y., Su, Y., Lou, J., Zhang, C., ... & Dai, M. (2024). Effect of C2H2 flow rate on microstructure, properties, and application in micro-drilling of aC: H films deposited by PECVD. Journal of Materials Research and Technology, 29, 1194-1205.

- Wei, R., Deng, J., Guo, X., Yang, Y., Miao, J., Liu, A., ... & Wang, R. (2024). Construction of zwitterionic coatings with lubricating and antiadhesive properties for invisible aligner applications. Macromolecular Rapid Communications, 2400234.

- Hu, L., Yu, W., Liu, J., Yang, Y., Hao, J., & Xu, L. (2024). Highly lubricative, self-healing, chemically degradable, anti-flaming and anti-irradiating magnetic gels simply prepared from binary mixtures of Fe 3 O 4 nanoparticles and water. Journal of Materials Chemistry A, 12(13), 7549-7563.

- Liao, M., Cammarata, A., & Polcar, T. (2024). Charge-induced ultralow friction between graphite and atomically flat surfaces. Carbon, 223, 119036.

- Chen, Y., Li, H., Su, F., Ma, G., Li, Q., Sun, J., & Lin, S. (2024). Friction and wear behavior of molybdenum-disulfide doped hydrogen-free diamond-like carbon films sliding against Al2O3 balls at elevated temperature. Wear, 544, 205296.

- Tang, G., Sun, S., Yang, J., Pan, Y., Liu, Z., & Liang, Z. (2024). Fabrication and tribological properties of WC-reinforced Inconel X-750 alloy at elevated temperature. Journal of Manufacturing Processes, 131, 1321-1333.

- Evans, T., & Palgrave, R. (2024). An investigative study on different magnetic ionic liquids to be used as a lubricant and sealant in a vacuum pump. Tribology and Materials, 3(1), 24-34.

- Ren, B., Su, Y., Lou, J., Zhang, C., Tang, P., Lin, S., ... & Zhou, K. (2024). PECVD technology deposition of high hardness aC: H films on micro-drill surfaces: Substrate bias voltage effects. Journal of Manufacturing Processes, 124, 385-398.

- Shi, H., Li, H., Guo, Z., Lu, H., Wang, J., & Li, J. (2024). GNBoost-Based Ensemble Machine Learning for Predicting Tribological Properties of Liquid-Crystal Lubricants. Langmuir, 40(20), 10705-10717.

- Men, S., Yang, P., Gyawali, G., Yang, Y., Li, D., Nouri, M., & Zhang, S. (2024). Insight into the corrosion behaviors and mechanism of arc discharge plasma nitrided H13 steel in molten Al-Si. Applied Surface Science, 670, 160584.

- Haider, S. B., Heon, E., Neveau, M., Chen, P., Houston, A., Rios, O., & Lass, E. A. (2024). Castable eutectic Ni–Ce high temperature alloys strengthened by γ/γʹ microstructure. Journal of Materials Research and Technology, 28, 3943-3950.

- Ren, Y., Liu, X., Chang, C., & Zhang, S. (2024). Tribological performance of c-BN/TiC-enhanced NiCrBSi coatings prepared by high-velocity oxy-fuel spraying tested from room temperature to 1000° C. Ceramics International, 50(13), 22947-22959.

- Tian, H., Cui, Z., Zhang, X., & Zhang, X. (2024). Effect of cathodic potential and corrosion product on tribocorrosion behavior of S420 steel in the marine environment. Materials Today Communications, 38, 108372.

- Liu, Q., Chen, X., Liu, K., Cristino, V. A., Lo, K. H., Xie, Z., & Kwok, C. T. (2024). Friction stir processing of M2 and D2 tool steels for improving hardness, wear and corrosion resistances. Surface and Coatings Technology, 481, 130609.

- Yurchenko, E. V., Ghilețchii, G. V., Vatavu, S. A., Petrenko, V. I., Harea, D., Bubulinca, C., & Dikusar, A. I. (2024). Composition, Structure, and Wear Resistance of Surface Nanostructures Obtained by Electric Spark Alloying of 65G Steel. Surface Engineering and Applied Electrochemistry, 60(2), 194-203.

- Xie, J., Li, P., Qian, Z., & Qian, Z. (2024). Wear simulation of pin-on-disc sliding wear test. In Journal of Physics: Conference Series (Vol. 2862, No. 1, p. 012040). IOP Publishing.

- Qi, Y., Gao, J., Liang, W., Miao, Q., Jia, F., Chang, X., & Lin, H. (2024). A comparison of the tribological properties of SiC coatings prepared via atmospheric plasma spraying and chemical vapor deposition for carbon/carbon composites. Lubricants, 12(9), 301.

- Kladovasilakis, N., Pechlivani, E. M., Sfampa, I. K., Tsongas, K., Korlos, A., David, C., & Tzovaras, D. (2024). Metal 3D-printed bioinspired lattice elevator braking pads for enhanced dynamic friction performance. Materials, 17(11), 2765.

- Elkington, R. J., Hall, R. M., Beadling, A. R., Pandit, H., & Bryant, M. G. (2024). Engineering tribological rehydration of cartilage interfaces: Assessment of potential polyelectrolyte mechanisms. Tribology International, 197, 109822.

- Buyuksungur, S., Parau, A. C., Dinu, M., Pana, I., Vitelaru, C., Schmidt, J., ... & Hasirci, N. (2024). Variations of chemical, physical, mechanical properties, and biological and antimicrobial effectiveness of Ti alloys by coating with CaP doped with different amounts of Zn via micro-arc oxidation (MAO) technique. Ceramics International, 50(19), 37096-37110.

- Zheng, X., Zheng, K., Jia, W., Qu, S., Yu, S., Zhou, B., ... & Gao, J. (2024). Plasma surface alloyed Ta diffusion layer and Ta coating on Ti6Al4V alloy: Mechanical and wear properties. Journal of Applied Physics, 136(2).

- Siahpour, P., Omar, S. M. T., Griffin, D., Amegadzie, M. Y., Tieu, A., Donaldson, I. W., & Plucknett, K. P. (2024). Evaluating surface mechanical properties and wear resistance of Ti–6Al–4V alloy subjected to ultrasonic pulsed waterjet peening. Wear, 550, 205400.

- Zhang, C., He, Y., Zhang, S., Li, C., Gou, R., Zhang, J., & Sun, D. (2024). A novel siloxene@ MoS2 heterostructure for improving the wear and corrosion resistance performance of epoxy coatings. Colloids and Surfaces A: Physicochemical and Engineering Aspects, 700, 134785.

- Chen, X., Sun, S., Wang, D., Li, J., Yang, C., Jiang, Y., & Chang, X. (2024). Construction of robust superhydrophobic surfaces with an'armour'structure on the low-temperature steels by picosecond laser processing. Tribology International, 195, 109637.

- Elkington, R. J., Hall, R. M., Beadling, A. R., Pandit, H., & Bryant, M. G. (2024). Brushing up on cartilage lubrication: Polyelectrolyte-enhanced tribological rehydration. Langmuir, 40(20), 10648-10662.

- Ozdemir, I., Bulbul, B., Kiracbedel, U., Grund, T., & Lampke, T. (2024). Wear Performance Evaluation of Polymer Overlays on Engine Bearings. Materials, 17(15), 3802.

- Escherová, J., Krbata, M., Kohutiar, M., Barényi, I., Chochlíková, H., Eckert, M., ... & Dubcová, P. (2024). The Influence of Q & T Heat Treatment on the Change of Tribological Properties of Powder Tool Steels ASP2017, ASP2055 and Their Comparison with Steel X153CrMoV12. Materials, 17(5), 974.

- Biedma, Á., Sánchez, G., de Nicolás, M., Bertalan, C., Useldinger, R., Llanes, L., & Gordo, E. (2024). A Comparative Study on the Wear Performance and High-Temperature Oxidation of Co-Free Cermets and Hardmetals. Materials, 17(14), 3615.

- Yin, Y., Shi, P., Zhang, S., Qing, T., Zhou, N., Qian, L., & Chen, L. Deeply Understanding Lubrication Failure of Steel Ball Against Oil-Impregnated Porous Polyimide in Double-Contact Friction with Rolling‑Sliding Motion. Available at SSRN 4692446.

- Park, J. E., Je, H., Kim, C. R., Park, S., Yu, Y., Cho, W., ... & Wie, J. J. (2024). Programming Anisotropic Functionality of 3D Microdenticles by Staggered‐Overlapped and Multilayered Microarchitectures. Advanced Materials, 36(7), 2309518.

- Yun, S., Um, Y., Park, H. W., & Kim, S. (2024). Static friction of magneto-rheological elastomer pads in wall-climbing robots. CIRP Annals, 73(1), 441-444.

- Wang, L., Ta, T., & Tieu, K. A. Tribological Roles of Glass‐Based Lubricants in Hot Rolling of Steel. steel research international, 2400107.

- Devenport, T. M., Lu, P., Rolfe, B. F., Pereira, M. P., & Griffin, J. M. (2024, October). Acoustic Emission Characteristics of Galling Behavior from Dry Scratch Tests at Slow Sliding Speed. In Acoustics (Vol. 6, No. 4, pp. 834-869). MDPI.

- Gong, L., Zhang, Z., Yu, W., Zeng, J., Cao, J., Fan, B., ... & Zhang, C. (2024). Ultra‐Durable Polysilicon Based Tribovoltaic Nanogenerators for Bearing In Situ Rotational Speed Sensing. Small, 20(50), 2405992.

Support

How Can We Help?

Bruker partners with our customers to solve real-world application issues. We develop next-generation technologies and help customers select the right system and accessories. This partnership continues through training and extended service, long after the tools are sold.

Our highly trained team of support engineers, application scientists and subject-matter experts are wholly dedicated to maximizing your productivity with system service and upgrades, as well as application support and training.