Nanoscale Thermal Analysis

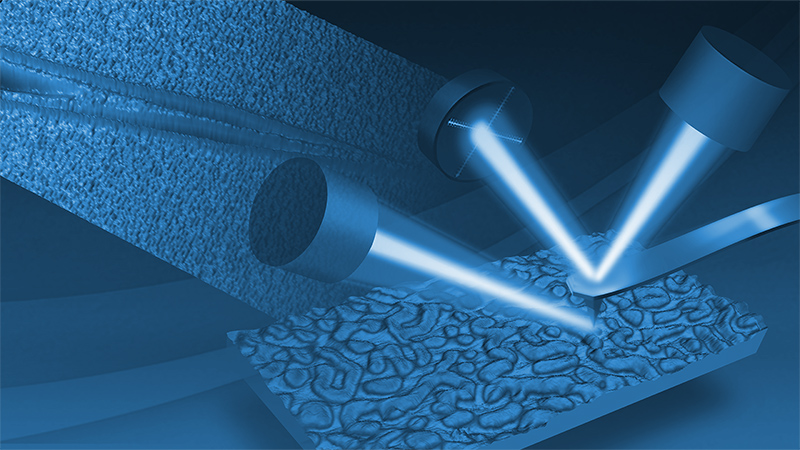

Nanothermal analysis, pioneered by Bruker, integrates with your AFM

Nanothermal analysis (nanoTA), pioneered by Bruker, is available as a module that integrates with your AFM. Hundreds of labs worldwide use nanoTA to go beyond the limits of traditional thermal analysis, achieving inisights into:

- Tg and Tm transition measurements on thin films and nanoscale domains within polymer blends

- Spatial variation of polymer cross-linking; Cure rates/defects in coatings

- Composite materials

- Transition temperature microscopy to quantify and map thermal transitions (TTM)

- Scanning thermal microscopy (SThM) for device failure analysis and other applications

AFM + Mechanical

Mechanical properties of your sample can be collected using a contact resonance method to map stiffness variations simultaneously with the topography. A 4µm x 8µm topography image and stiffness map of a three-component polymer blend. The stiffness map, which measures the variation in modulus by analyzing the contact resonance of the cantilever, clearly resolves the three materials.

Nanomechanical and Nanothermal Property Mapping

Lorentz Contact Resonance (LCR) simplifies component selective imaging in polymer blends. Above: Height (left) and LCR images (center, right) of a blend of polystyrene (PS) and low density polyethylene (LDPE). The LCR images were obtained at two different contact resonance frequencies corresponding to strong resonances of the PS (center) and LDPE (right).

Life Sciences

Height (top) and Lorentz Contact Resonance composite image (bottom) of wood cell walls. The bottom image is a three color overlay obtained at three different contact resonance frequencies selected to highlight the different wood cell components.

Nanoscale Thermal Analysis (nanoTA)

An AFM image with nanoTA data of a toner particle. The particle was embedded in epoxy and microtomed. The topography of the sample shows variations in structure, which can then be analyzed using nanoTA. Toner particles include a number of components (wax, resin, dye, etc.) that exhibit different transition temperatures.

Scanning Thermal Microscopy (SThM)

The 4µm x 8µm image shown here utilizes the scanning thermal microscopy (SThM) functionality of the afm+ system on a carbon fiber – epoxy composite sample. The sample was cut and polished to form a smooth surface. The height image (left) shows a number of carbon fibers, while the SThM image (right) shows the change in probe temperature on the two materials due to their differences in thermal conductivity. This sample demonstrates the high lateral-resolution capability of the SThM technique.

Transition Temperature Microscopy (TTM)

An optical image and a TTM map of a banded spherulite composed of poly (L-lactic acid) (PLLA). This TTM map was created by using the motorized XY stage. The blue areas in the TTM map are amorphous PLLA; the red and yellow areas are crystalline areas. The “onion-like” structure in the spherulite was created by stepping the temperature back and forth during the crystallization process to create regions with a higher or lower degree of crystallinity. Sample courtesy of J. Morikawa, Tokyo Institute of Technology.