XFlash® FlatQUAD - Annular EDS Detector

Taking Energy Dispersive X-ray Spectroscopy to New Limits

XFlash® FlatQUAD is a novel EDS detector designed for maximum signal collection, opening up new application areas for EDS:

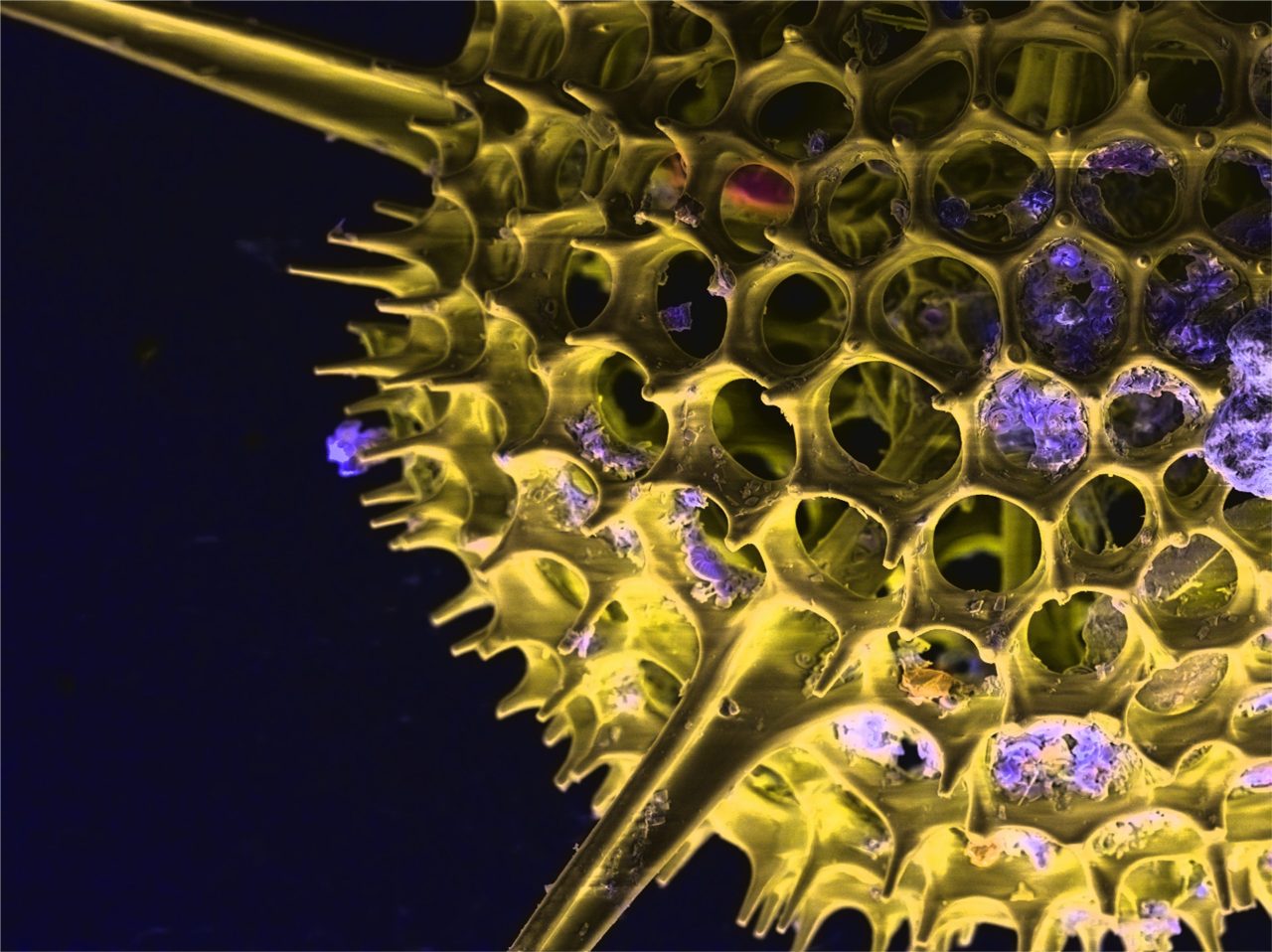

- Perform SEM EDS at ultra-high resolutions down to the nanometer scale.

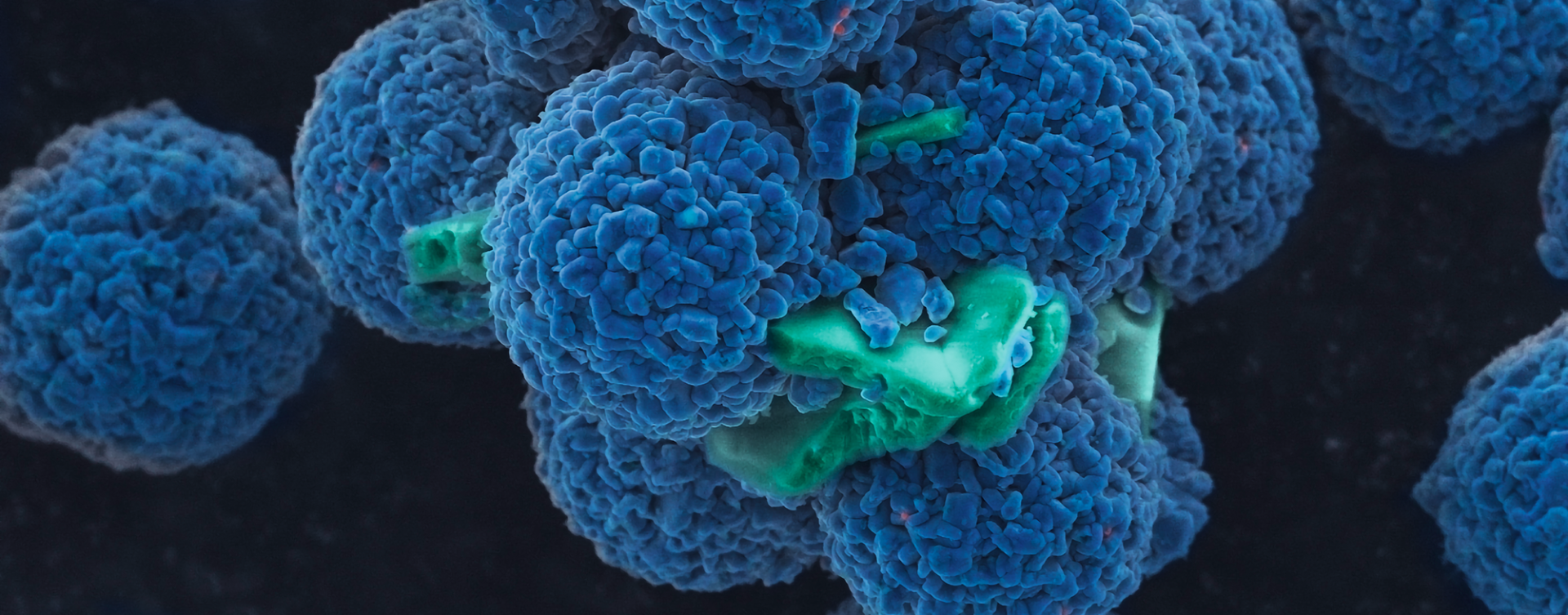

- Map the elements in delicate or charging samples.

- Carry out elemental analysis at high-throughput.

- Determine the elemental composition of topographic samples.

- Perform TEM-like EDS using a SEM.

Excellent Solid Angle and Count Rate Capability

The position and size of the detector chips provide the largest solid angle for X-ray collection in a SEM. Depending on the specific geometrical conditions more than 1 sr is possible in combination with a high take-off angle of 60° or more. The collection efficiency can lead to extremely high count rates.

All four detector chips are therefore equipped with separate signal processing channels. This allows input count rates (ICR) of up to 8,000,000 cps and a combined output count rate (OCR) of up to 3,200,000 cps.

XFlash® FlatQUAD provides an excellent energy resolution of 127 eV at Mn Kα. Resolution classes of 129 eV and 133 eV are also available.

Discover QUANTAX FlatQUAD

XFlash® FlatQUAD is the detector at the core of our QUANTAX FlatQUAD analytical system - discover more about QUANTAX FlatQUAD here.