Petroleum Process and Product Analysis

Petrochemical Product Analysis

Refinery and cracker operations have become more complex with tighter margins, requiring a renewed focus on process control, feedstock analysis, and product quality control. Advanced analysis of the composition of petroleum enables operators to optimize refinery operations more profitably. Additionally, expanding regulatory controls on fuels require reliable and easy to use routine analysis. Bruker is committed to the downstream and petrochemical segment, with dedicated solutions and expertise in implementing new or improved workflows. Bruker provides go to solutionsWe are your partner in petrochemical product analysis and process control solutions.

Petrochemical Quality Testing and Process Control with XRF

Elemental analysis is a crucial process control tool for petrochemical refinement: XRF is employed as a technique to quantify sulfur in crude oil, liquid streams and in refined products, as well as to quantify Ni, Fe and V in crude oils.

As XRF can analyze the sample directly without digestion or dilution it is widely employed as process tool. Sulfur levels in fuels are regulated, compliance analysis can be performed with XRF to adhere to ASTM, ISO or other established norms. Residual fuel oils as well as solid petcoke can also be directly analyzed.

Low detection limits for critical elements in petrochemical products is essential for process control and compliance. The S8 TIGER WD-XRF spectrometer is engineered for with demanding petrochemical applications in mind, with the ultra-low level detection of elements like phosphorus, lead, sulfur, nickel, and vanadium and a specialized SampleCare™ liquid handling system for safe, leak-free sample containment.

Screening for Sulfur and Other Critical Elements in Refineries

Sulfur concentrations in automotive fuels are subject to strict global regulations, often limited to 10 ppm. Consistent monitoring of ultra-low sulfur levels in diesel and gasoline is essential throughout the supply chain - from refining to storage and distribution. Other critical elements such as Ni, V, Fe, and Cl must also be monitored as their presence can negatively impact the behavior and properties of the refined product.

The S2 POLAR provides fast and reliable XRF analysis for sulfur and other critical elements, supporting process control and compliance with international standards including ASTM, ISO, IP, and JIS.

IMO 2020: Sulfur Analysis in Marine Fuels

The International Convention for the Prevention of Pollution from Ships (MARPOL) carriage ban on non-compliant fuel oil went into effect on March 1, 2020. Quickly and accurately measure sulfur in marine fuels to ensure bunker fuels meet regulations in Emission Control Areas and other restricted locations. This method follows ASTM D4294 higher concentration range of 0.1 to 5.0% Sulfur in Fuel and ISO 8754:2003. Suppliers, engineers, ship captains and inspectors can use our portable XRF Sulfur Measurement solutions at service labs, supply stations, on docks, in ports, and even aboard barges and ships.

Bruker’s CTX portable XRF spectrometer provides a reliable and inexpensive verification of sulfur in fuel onboard or at the terminal.

FT-NIR in Fuel & Analysis

Gasoline, Diesel and Jet fuels require extensive testing in the laboratory for process optimization, blend optimization and efficiency and to reduce the instance of octane giveaway. Previously, this required many independent tests including simulated distillation, GC and Knock Engine Testing. New advances in Fourier Transform Near Infrared spectroscopy now mean that multiple chemical and& physical properties can be derived from one sample/one spectrum in seconds. Properties include:

- RON, MON, PON

- RVP, T5, T10, T50, T90, T95, IBP, FBP

- Benzene, Aromatics, Olefins, Saturates

Bruker has developed unique solutions for the refinery fuels laboratories which includes calibrations developed using many thousands of fuel samples.

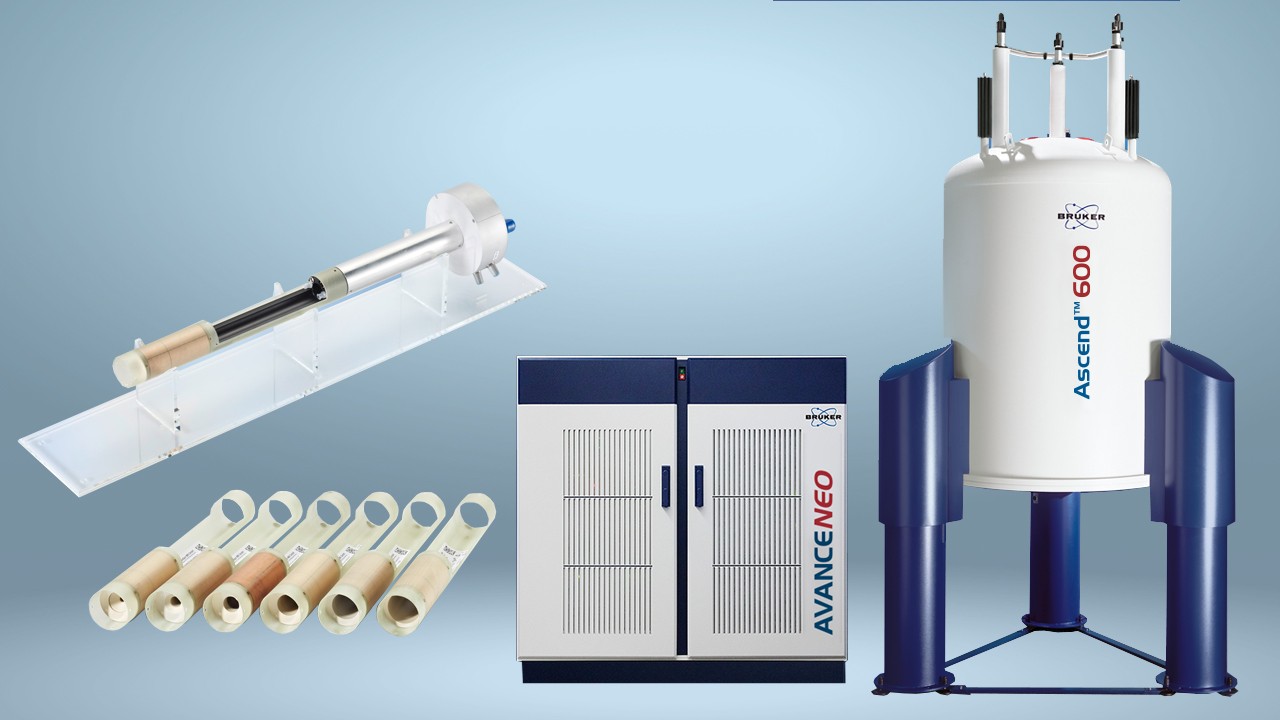

Petroleomics: The Molecular Classification of Petroleum

A detailed knowledge of the exact chemical composition of crude oil and crude oil fractions is in high demand within the oil industry. Crude oils with similar or even identical bulk chemical properties can behave completely different. Examples include reacting differently in the refinery processes, where specific compounds and compound classes can cause catalytic deactivation.

Flow assurance interests are with polar compounds in crude oil containing hetero atoms such as nitrogen, sulfur and oxygen having a high contribution in deposition and clogging of pipelines. Even in oil exploration, the exact chemical class information can be useful for reservoir connectivity studies.

Therefore, detailed information on relative abundances of those problematic compound classes is of major interest.

The relative abundance of compound classes, as well as detailed core structural information of classes based on ring and double bond equivalents can be derived by ultra-high resolution mass spectrometry.

Crude oils can be analyzed without any sample purification within minutes using different ionization methods (APPI, ESI, LDI). Mass spectrometric data are then processed using advanced software solutions (PetroOrg/Composer).

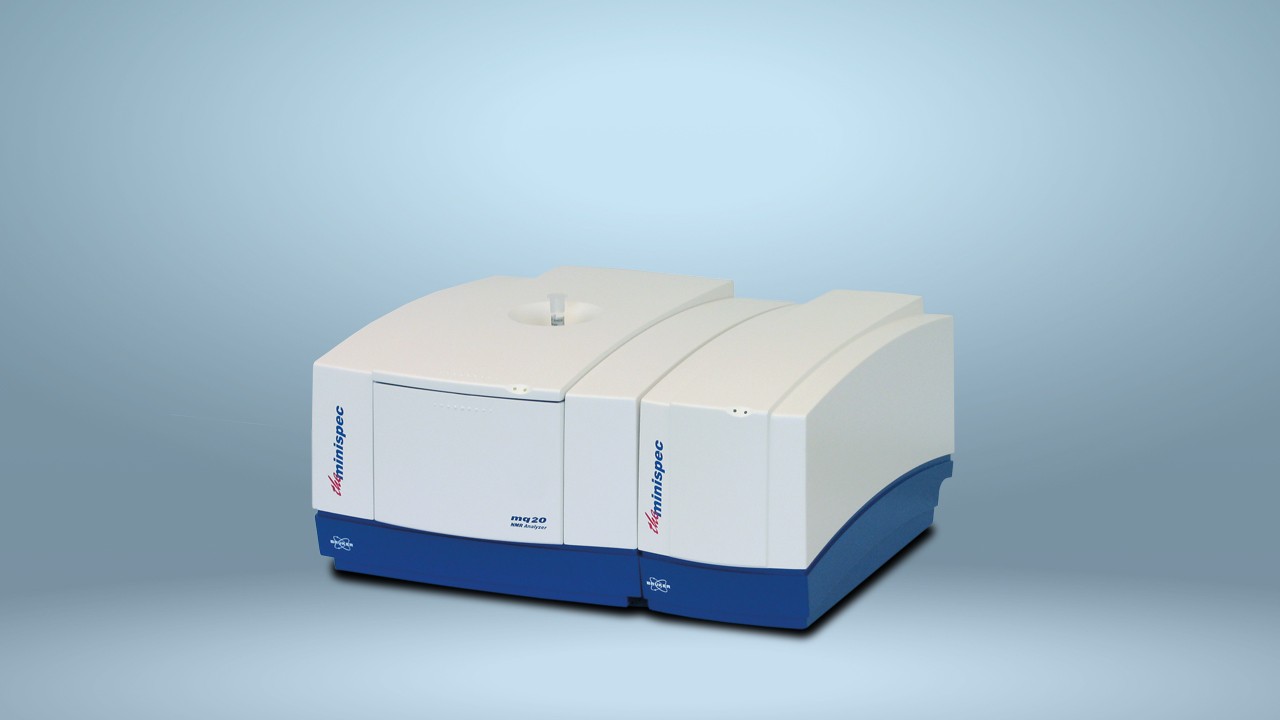

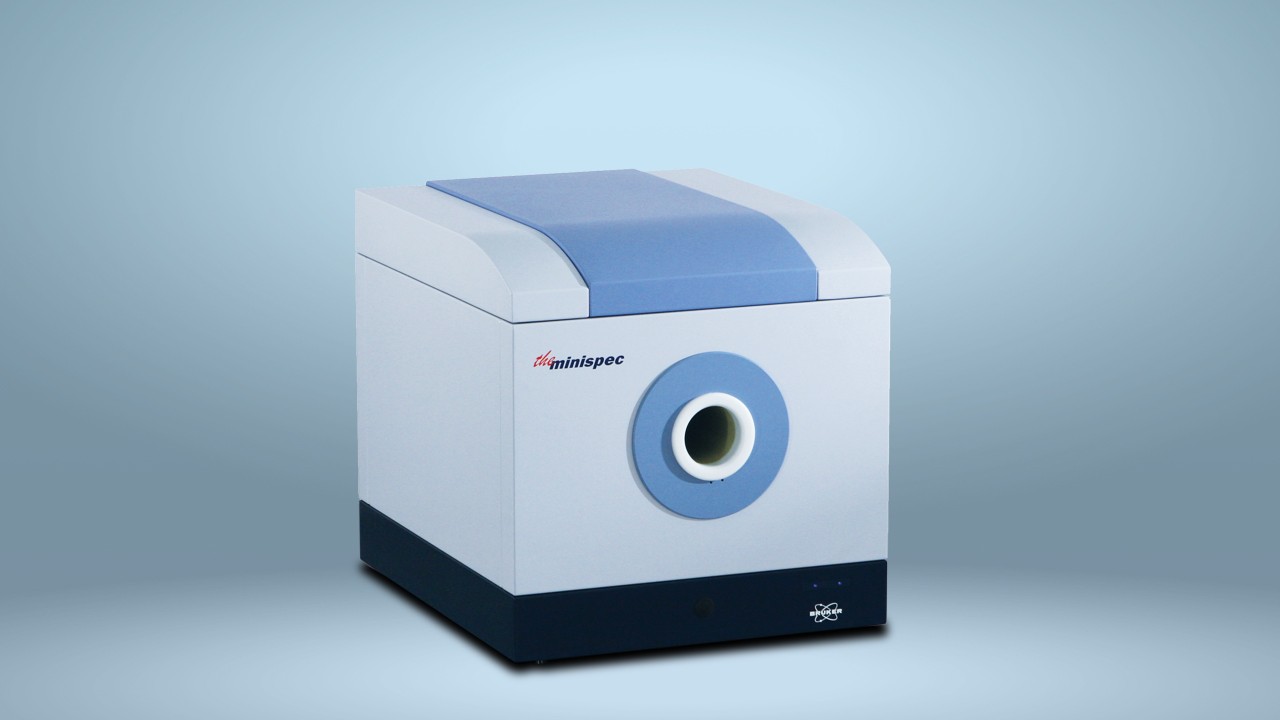

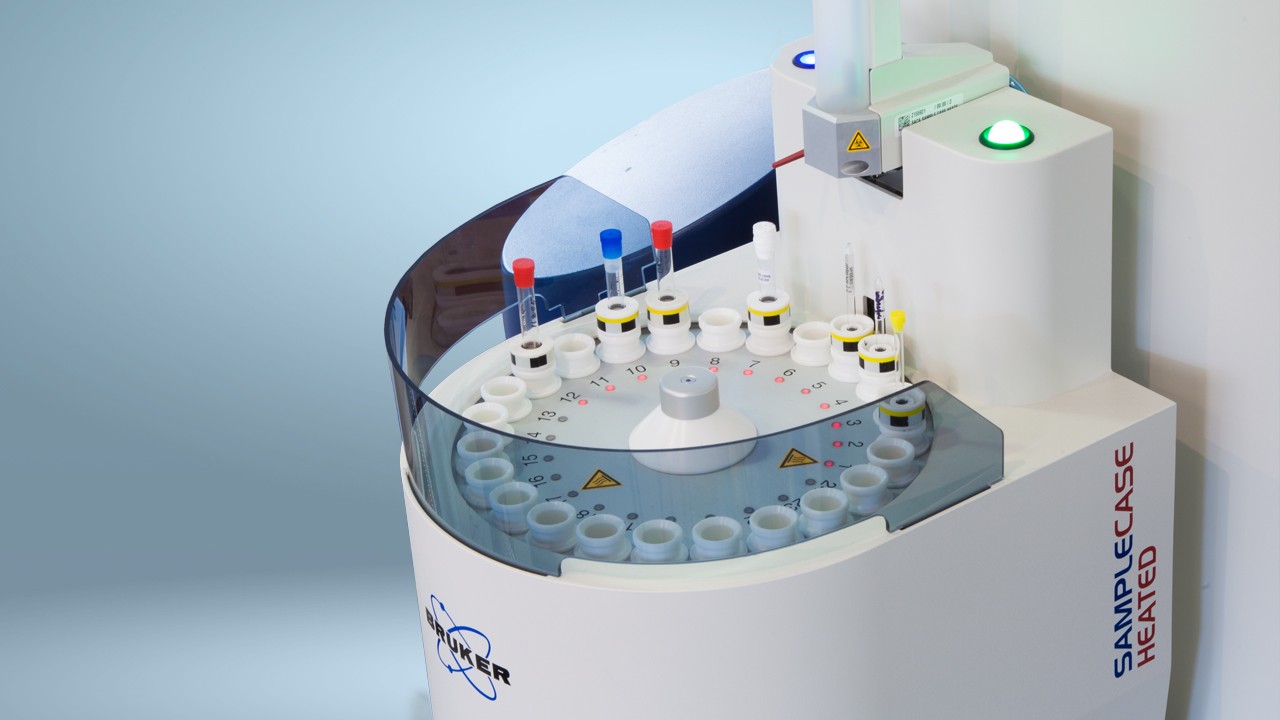

TD-NMR Hydrocarbon Analysis

Time Domain Nuclear Magnetic Resonance (TD-NMR), also called Low Resolution NMR, is an affordable NMR solution for petroleum and processes analysis. Magnetic field relaxation times can be used to determine physical and chemical properties, including:

Crude Oil Analyses

- Viscosity

- Droplet size distribution (oil-in-water, water-in-oil)

- Hydrogen content

Distillation Monitoring

- % Hydrogen in seconds (ASTM techniques)

- Automated hydro-cracking process control

Oil Sand Separation

- Real-time monitoring of bitumen, water, solvents in separation samples

- Sample size: few mg to 1000g

- No sample preparation necessary

- Color, opacity does not affect measurement

- Simple and short calibration procedure

NMR for Fuel Analysis

NMR has found application in the fuel industry since its inception as a commercial product, and the fuel additives field has since become a heavily studied area of the industry. Often, fuel companies will carry out this research themselves and use NMR to acquire detailed information on the chemical makeup of raw petroleum.

Publications Related to Petroleum Process and Product Analysis

- 2017 - Fuel: Fractionation of asphaltenes in n-hexane and on adsorption onto CaCO3 and characterization by ESI(+)FT-ICR MS: Part I

- 2014 - Fuel: Monitoring the degradation and the corrosion of naphthenic acids by electrospray ionization Fourier transform ion cyclotron resonance mass spectrometry and atomic force microscopy