Hysitron PI 89

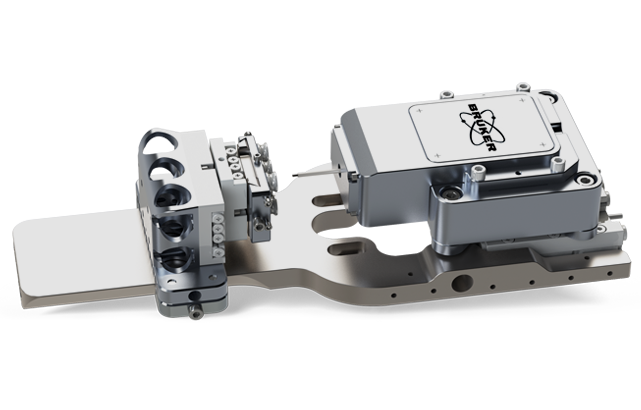

Hysitron PI 89 SEM PicoIndenter

The Hysitron PI 89 SEM PicoIndenter leverages the advanced imaging capabilities of scanning electron microscopes (SEM, FIBSEM, PFIB), making it possible to perform quantitative nanomechanical testing while simultaneously imaging. PI 89 further advances Bruker's market-leading capacitive transducer technology, which enabled the first commercial in-situ SEM nanomechanics platforms. The new PI 89 Auto adds full automation to four techniques: EBSD, EDS, SEM imaging, and mechanical property mapping.

Techniques available on PI 89 include nanoindentation, tensile testing, pillar compression, particle compression, cantilever bending, fracture, fatigue, dynamic testing, and mechanical properties mapping.

To learn more, continue reading, dowload the brochure, or see FAQs about this product.

Advanced Performance and Functionality

The compact design of Hysitron PI 89 allows for maximum stage tilt and minimum working distance to enable optimal imaging during testing. PI 89 offers researchers greater versatility and performance than competing systems:

- Redesigned platform increases versatility and ease of use

- 1 nm encoded linear stages provide greater repeatability during automated testing modes while increasing travel range

- Improved frame stiffness (~0.9 x 106 N/m) delivers greater stability throughout the testing process

- Rotation and tilt (RT) stage configurations enable imaging, FIB milling, and access to detectors, such as EDS, CBD, EBSD, and TKD for analytical data and imaging

True Displacement Control

Hysitron PI 89 utilizes Bruker’s proprietary sub-nanometer sensitivity transducer and piezo-driven flexure for intrinsically displacement-controlled and load-controlled tests:

- In intrinsically displacement-control mode, the piezo actuator can apply displacement with a predetermined displacement rate, and the transducer measures the force

- In true load-control mode, the transducer can apply force electrostatically while simultaneously measuring displacement capacitively

- The uniquely low-current design of the transducer minimizes thermal drift and provides unprecedented load and displacement sensitivity

In-Situ Mechanical Data Synchronized with SEM Imaging and Analytical Mapping

In-situ mechanical data acquired with the Hysitron PI 89 are synchronized with SEM imaging and displayed side-by-side. This allows you to see the influence of defects, mechanical strain, and thermal or electrical stimuli on the performance, lifetime, and durability of engineered materials—from nanometer-to-micrometer scales. This synchronization enables a greater range of analyses:

- The rotation and tilt stages of the SEM offer a combination of EBSD and mechanical property mapping of samples

- FIB milling can be performed on a sample before and after nanomechanical testing, without venting a chamber

Automated Co-Localized Imaging and Analysis for High-Throughput In-Situ Nanoindentation

Bruker's new Hysitron PI 89 Auto SEM PicoIndenter enables full automation of four techniques: EBSD, EDS, SEM imaging, and mechanical property mapping.

Customizable for your research.

Expand PI 89's Capabilities

LEARN MORE:

Contact us for more information about available upgrade options and how PI 89 can be configured to meet your specific measurement needs now and grow with your research going forward.

Watch our Recent Broadcasts on Nanomechanics in SEM

Our webinars cover best practices, introduce new products, provide quick solutions to tricky questions, and offer ideas for new applications, modes or techniques.

Frequently Asked Questions

Hysitron PI 89 supports a full suite of in-situ testing techniques and options, including nanoindentation, compressions, elevated temperature (>1000oC), cryogenic temperature, nanoTribology, electrical characterization, nanoDynamic, Push-to-Pull (PTP), direct-pull tension, Electrical Push-to-Pull (EPTP), high strain rate, and scanning probe microscopy imaging.

PI 89 offers rotation and tilt (R/T) stage configurations to give access to EBSD and other detectors. For full access to all detectors, the instrument should operated with an optimal stage configuration and working distance, and fixtures and cabling should not be obstructing any detectors.

Transducers and flexures are interchangeable components of PI 89. Transducers are available with an extended force range from 10 mN to 3.5 N. On PI 89, the Mechanically Amplified (MA) Flexure provides a 150 µm displacement range, and the Direct Drive (DD) Piezo Flexure provides a 30 µm displacement range with improved displacement control.

Contact us to discuss what transducer and flexure options will be the best fit for your experiments.

PI 89 offers a broad catalog of tips in multiple geometries and materials, including diamond, sapphire, vanadium carbide, boron nitride, tungsten, and steel. Tips are selected according to test mode and sample material. Contact us for help selecting the appropriate tip for your research.

Key Publications with SEM

- Aleman, Angel, Hicham Zaid, Koichi Tanaka, Jenn-Ming Yang, Suneel Kodambaka, and Hanna Kindlund. 2024. “Unusual Secondary Slip Activity at Room Temperature in VC Single Crystals.” Materials & Design 244 (August): 113195. https://doi.org/10.1016/j.matdes.2024.113195.

- An, Qi, Zhe Yan, Lichen Bai, and Shijian Zheng. 2024. “Achieving Superior Matching of Strength, Plasticity, and Strain Hardening in Multilayers by Introducing Metastable Amorphous Interface Phase.” Scripta Materialia 252 (November): 116258. https://doi.org/10.1016/j.scriptamat.2024.116258.

- Bignoli, Francesco, Philippe Djemia, Giancarlo Terraneo, Gregory Abadias, Christoph Gammer, Alice Lassnig, Camila A. Teixeira, et al. 2024. “Novel Class of Crystal/Glass Ultrafine Nanolaminates with Large and Tunable Mechanical Properties.” ACS Applied Materials & Interfaces 16 (27): 35686–96. https://doi.org/10.1021/acsami.4c02610.

- Bijun Xie, Hangman Chen, Pengfei Wang, Cheng Zhang, Bin Xing, Mingjie Xu, Xin Wang, Lorenzo Valdevit, Julian Rimoli, Xiaoqing Pan, Penghui Cao. 2024. “Divergent Evolution of Slip Banding in Alloys.”

- Cao, Qingping, Nan Wang, Jae-Moo Kim, Arnaud Caron, Zhipeng Zhang, Haofei Zhou, Xiaodong Wang, Shaoqing Ding, Dongxian Zhang, and Jian-Zhong Jiang. 2024. “A Dual-Phase Fe-Co-Ni-Cr-Mn High Entropy Alloy Thin Film with Superior Strength and Corrosion-Resistance.” Journal of Alloys and Compounds 1003 (October): 175551. https://doi.org/10.1016/j.jallcom.2024.175551.

- Dabney, Tyler Alexander. 2024. “Development of Cold Spray Cr Coatings on Zr-Alloy for Advanced Nuclear Fuel Cladding.”

- Duan, Fenghui, Qian Li, Zhihao Jiang, Lin Zhou, Junhua Luan, Zheling Shen, Weihua Zhou, et al. 2024. “An Order-Disorder Core-Shell Strategy for Enhanced Work-Hardening Capability and Ductility in Nanostructured Alloys.” Nature Communications 15 (1): 6832. https://doi.org/10.1038/s41467-024-50984-9.

- Flamourakis, George, IOANNIS SPANOS, Zacharias Vangelatos, Costas Grigoropoulos, Anthi Ranella, and Maria Farsari. 2024. “Laser-Made Mechanical Metamaterials: Towards the Development of 4D Scaffolds for Cell Growth.” In Nanoscale and Quantum Materials: From Synthesis and Laser Processing to Applications 2024, edited by Andrei v. Kabashin, Maria Farsari, and Masoud Mahjouri-Samani, 11. SPIE. https://doi.org/10.1117/12.3004008.

- Gasper, C., I. Y. Gao, F. A. Busch, A. Ziemons, D. Beckers, H. Springer, and S. Korte-Kerzel. 2024. “Preparation of Binary and Ternary Laves and Μ-Phases in the Ta–Fe(–Al) System for Property Analysis at the Microscale.” Metallurgical and Materials Transactions A 55 (7): 2244–63. https://doi.org/10.1007/s11661-024-07390-z.

- Ghodki, Nandita, Shristy Jha, Siva Shankar Alla, Yu-Chia Yang, George M. Pharr, and Sundeep Mukherjee. 2024. “Deformation Behavior of Thermally Rejuvenated Zr-Cu-Al-(Ti) Bulk Metallic Glass.” Scientific Reports 14 (1): 20729. https://doi.org/10.1038/s41598-024-71658-y.

- Gunjal, Vilas, Chandra Sekhar Tiwary, Kamanio Chattopadhyay, and Dipankar Banerjee. 2024. “Intermetallic Eutectics with Gigapascal Strength and Enhanced Ductility.” Intermetallics 168. https://doi.org/10.1016/j.intermet.2024.108228.

- Ha, Sangyul, Saif Haider Kayani, Kyungjun Lee, Suwon Park, Hyunjoo Choi, Jae Bok Seol, Jung Gi Kim, and Hyokyung Sung. 2024. “Microscopic-Plastic Deformation Behavior of Grain Boundary Precipitates in an Al–Zn–Mg Alloy.” Journal of Materials Research and Technology 30 (May): 3420–29. https://doi.org/10.1016/j.jmrt.2024.04.044.

- Hazendonk, Laura S. van, Zafeiris J. Khalil, Wilko van Grondelle, Levina E. A. Wijkhuijs, Ingeborg Schreur-Piet, Michael G. Debije, and Heiner Friedrich. 2024. “Hot Fingers: Individually Addressable Graphene-Heater Actuated Liquid Crystal Grippers.” ACS Applied Materials & Interfaces 16 (25): 32739–47. https://doi.org/10.1021/acsami.4c06130.

- Hong, Jong-Dae, Hongryul Oh, Daehyeok Ahn, Dongchan Jang, Hyun-Gil Kim, JaeYong Kim, Hyochan Kim, and Martin Ševeček. 2024. “Micro-Mechanical Evaluations of Adhesion Properties for Cr-Coated Accident Tolerant Fuel Cladding.” Nuclear Materials and Energy 41 (December): 101799. https://doi.org/10.1016/j.nme.2024.101799.

- Horbach, Lutz, Jiali Zhang, Tobias Sedlatschek, Felix Weber, Christian Gebhardt, Betto David Joseph, Andreas Bührig-Polaczek, and Christoph Broeckmann. 2024. “The Effect of Silicon on the Critical Resolved Shear Stress of Solid Solution Strengthened Ferritic Ductile Iron.” Materials & Design 244 (August): 113130. https://doi.org/10.1016/j.matdes.2024.113130.

- Hou, Jingkun, Xianzhang Wu, Zhihan Li, Xingchi Li, Yu Liao, Lei Li, Sha Luo, Yiqiang Wu, and Yan Qing. 2024. “Aligned Bamboo Fiber‐Induced Crystallinity Mitigation of Lightweight Polymer Composite Enables Ultrahigh Strength and Unprecedented Toughness.” Advanced Functional Materials 34 (27). https://doi.org/10.1002/adfm.202314559.

- Hu, C., Y.X. Liu, B.B. He, and M.X. Huang. 2025. “Role of Intermetallic Networks in Developing High-Performance Austenitic Steel.” Acta Materialia 283 (January): 120494. https://doi.org/10.1016/j.actamat.2024.120494.

- Jang, Dongchan, Woosuk Seo, Daehyeok Ahn, Hadi Ghaffarian, Tae-Ho Lee, Eun-Soo Park, Keumhwan Park, and Yongjo Kim. 2024. “Design and Fabrication of Highly Elastic and Largely Deformable Nanolaminate Amorphous-Crystalline Metallic Electrodes for Deformable Displays.” https://doi.org/10.21203/rs.3.rs-4539893/v1.

- Janknecht, Rebecca, Rainer Hahn, Nikola Koutná, Tomasz Wójcik, Eleni Ntemou, Andreas Steiger-Thirsfeld, Zhuo Chen, et al. 2024. “A Strategy to Enhance the B-Solubility and Mechanical Properties of Ti–B–N Thin Films.” Acta Materialia 271 (June): 119858. https://doi.org/10.1016/j.actamat.2024.119858.

- Jha, Shristy, Siva Shankar Alla, Sanjit Bhowmick, and Sundeep Mukherjee. 2025. “Temperature Dependent Small-Scale Deformation of a Refractory High Entropy Alloy.” Materials Letters 379 (January): 137649. https://doi.org/10.1016/j.matlet.2024.137649.

- Kakaraparty, Karthik, Erik A. Pineda, Baylee Schumacher, Russell C. Reid, and Ifana Mahbub. 2024. “Advanced Bias-Free Energy Harvesting Based on High-Dielectric Flexible Electrodes with Reverse Electrowetting-on-Dielectric.” IEEE Sensors Journal 24 (7). https://doi.org/10.1109/JSEN.2023.3345841.

- Kim, Ho A., Ju Seong Kim, Yundong Lee, Sangbum Kim, Youho Lee, Yong Soo Kim, Joo Hee Kang, and Sangtae Kim. 2024. “Microstructure and Mechanical Properties of Hydride Blisters Formed on Zircaloy-4 Claddings.” Journal of Nuclear Materials 588. https://doi.org/10.1016/j.jnucmat.2023.154777.

- Lam, S., D. Frazer, F. Cappia, M. Nelson, S. Samuha, S. Pitts, B. Harris, and P. Hosemann. 2025. “Length Scale Effects of Micro- and Meso‑scale Tensile Tests of Unirradiated and Irradiated Zircaloy-4 Cladding.” Journal of Nuclear Materials 604 (January): 155469. https://doi.org/10.1016/j.jnucmat.2024.155469.

- Lee, Do Hoon, Taesu Lim, Jeongsu Pyeon, Hyunmin Park, Sang‐Won Lee, Seungkyu Lee, Wonsik Kim, et al. 2024. “Self‐Mixed Biphasic Liquid Metal Composite with Ultra‐High Stretchability and Strain‐Insensitivity for Neuromorphic Circuits.” Advanced Materials 36 (16). https://doi.org/10.1002/adma.202310956.

- Lehnert, R., V. Remich, G. Gerstein, M. Motylenko, M. Müller, P. Krooß, T. Niendorf, H. Biermann, and A. Weidner. 2024. “Unraveling Factors Affecting the Reversibility of Martensitic Phase Transformation in FeNiCoAlTi Shape Memory Alloys: Insights from HR-EBSD and Acoustic Emission Analysis.” Acta Materialia 276 (September): 120146. https://doi.org/10.1016/j.actamat.2024.120146.

- Leide, Alex, Eric Hintsala, Mark Davies, David T. Goddard, and Dong Liu. 2024. “Micromechanical Properties of TRISO Coatings by In-Situ High Temperature Nanoindentation and Microcantilever Fracture.” Journal of the European Ceramic Society 44 (5). https://doi.org/10.1016/j.jeurceramsoc.2023.12.056.

- Li, Bo, and Xiaolong Song. 2024. “Structural Evolution and Micromechanical Property of Amorphous Carbon Particles during Arc Plasma Synthesis.” Materials Letters 372 (October): 137106. https://doi.org/10.1016/j.matlet.2024.137106.

- Li, Lu, Xiali Zhen, Ruixiao Zheng, Chaoli Ma, and Cuiyun Liu. 2024. “Further Understanding of the Improved Mechanical Properties for SiCf/BN/SiC Composites Prepared by CVI+PIP Hybrid Technique: Application of Micro-Mechanical Methods.” Composites Part B: Engineering 283 (August): 111633. https://doi.org/10.1016/j.compositesb.2024.111633.

- Li, Weiming, Lichen Bai, Kaisheng Ming, and Shijian Zheng. 2024. “Plasticity Dependence on Amorphous Continuity in Fe‐SiOC Dual‐phase Nanocomposites.” Journal of Materials Science and Technology. https://doi.org/10.1016/j.jmst.2023.08.005.

- Li, Yanxiao, Congjie Wei, Steven E. Kooi, David Veysset, Chuanrui Guo, Yuxiang Gan, Ying Zhuo, et al. 2024. “Tough Monolayer Silver Nanowire-Reinforced Double-Layer Graphene.” ACS Applied Materials & Interfaces, October. https://doi.org/10.1021/acsami.4c04768.

- Liang, Zhao, and Eugen Rabkin. 2024. “The Effect of Composition and Long-Range Order on the Strength of Defect-Free Faceted Cu-Au Nanoparticles.” Acta Materialia 266. https://doi.org/10.1016/j.actamat.2024.119680.

- Liu, Chang, Jing Rao, Zhongji Sun, Wenjun Lu, James P. Best, Xuehan Li, Wenzhen Xia, et al. 2024. “Near-Theoretical Strength and Deformation Stabilization Achieved via Grain Boundary Segregation and Nano-Clustering of Solutes.” Nature Communications 15 (1): 9283. https://doi.org/10.1038/s41467-024-53349-4.

- Liu, Shirong, Jingui Ai, Yueqi Zhang, and Jicheng Feng. 2024. “Programmable and Parallel 3D Nanoprinting Using Configured Electric Fields.” Advanced Functional Materials 34 (13). https://doi.org/10.1002/adfm.202308734.

- Luo, W., C. Gasper, S. Zhang, P.L. Sun, N. Ulumuddin, A. Petrova, Y. Lysogorskiy, R. Drautz, Z. Xie, and S. Korte-Kerzel. 2024. “Non-Basal Plasticity in the μ-Phase at Room Temperature.” Acta Materialia 277 (September): 120202. https://doi.org/10.1016/j.actamat.2024.120202.

- Moon, Jaron v., Md Takmil Sakir, Wooseok Go, Rui Xie, Michael C. Tucker, Marca Doeff, Haoran Wang, and Roseanne Warren. 2024. “Microscale Mechanical Property Variations of Al-Substituted LLZO: Insights from Compression Testing and Molecular Dynamics Simulations.” Journal of Materials Chemistry A 12 (37): 24886–95. https://doi.org/10.1039/D4TA03596H.

- Musiienko, Denys, Jaromír Kopeček, Ross H. Colman, Kari Ullakko, and Oleg Heczko. 2024. “Increase of Twinning Stress in Single Crystalline Ni-Mn-Ga Micropillars.” Materialia 33. https://doi.org/10.1016/j.mtla.2023.101988.

- Pan, Bo, Hui Sun, Dongyue Xie, Shun Li Shang, Nan Li, Blair E. Carlson, Yumeng Li, Zi Kui Liu, and Jingjing Li. 2024. “Influence of Accelerated Corrosion on Al/Steel RSW Joints by in Situ Compression Tests.” Materials Science and Engineering: A 889. https://doi.org/10.1016/j.msea.2023.145851.

- Paul, Tanaji, Tyler Dolmetsch, Lihua Lou, and Arvind Agarwal. 2024. “Frictional Resistance and Delamination Mechanisms in 2D Tungsten Diselenide Revealed by Multi-Scale Scratch and in-Situ Observations.” Nanotechnology 35 (39): 395703. https://doi.org/10.1088/1361-6528/ad5dbe.

- Pena, Miguel, Yongchang Li, Zhihan Hu, Kenneth Cooper, Laura Hawkins, Di Chen, Frank A. Garner, and Lin Shao. 2024. “Micro-Pillar Compression of Proton-Irradiated Chromium Examined Using Cross-Sectional Site Selection, Electron Microscopy, and Molecular Dynamics Simulation.” Journal of Nuclear Materials 600 (November): 155299. https://doi.org/10.1016/j.jnucmat.2024.155299.

- Peng, Hui Wen, and Chun Hway Hsueh. 2024. “Effects of Silicon and Neodymium Additions on Microstructures and Mechanical Properties of CoCrNi Medium Entropy Alloy Films.” Surface and Coatings Technology 476. https://doi.org/10.1016/j.surfcoat.2023.130206.

- Prasitthipayong, A., D.M. Frazer, R. Zhang, H.T. Vo, S.J. Tumey, A.M. Minor, and P. Hosemann. 2024a. “Sample Size Effect Phenomenon in Microcompression Testing of Unirradiated and Ion-Irradiated 800H Steel at High Temperatures.” Materials Characterization 215 (September): 114046. https://doi.org/10.1016/j.matchar.2024.114046.

- 2024b. “Sample Size Effect Phenomenon in Microcompression Testing of Unirradiated and Ion-Irradiated 800H Steel at High Temperatures.” Materials Characterization 215 (September): 114046. https://doi.org/10.1016/j.matchar.2024.114046.

- Puttbach, C., G.S. Prinz, and C.D. Murray. 2024. “Strength and Stiffness Characterization of Ultra-High Performance Concrete (UHPC) Cement Paste Phases through in-Situ Micro-Mechanical Testing.” Cement and Concrete Composites 149 (May): 105520. https://doi.org/10.1016/j.cemconcomp.2024.105520.

- Rivera, Charles. 2024. “Development of a Thermal Micro Tensile Testing Technique for Select Layer Interfaces of TRISO Particles.”

- Robinson, Accalia, Eric Hintsala, Eric R. Homer, and Gregory B. Thompson. 2024. “Temperature Dependent Twin Stability in Nanocrystalline Cu(Al) Under In-Situ Cryogenic Pillar Compression.” https://doi.org/10.2139/ssrn.4902256.

- Schmalbach, Kevin M, Justin Y Cheng, Eric D Hintsala, Nathan A Mara, Douglas D Stauffer, and Sanjit Bhowmick. 2024. “Accelerated Microstructure-Mechanical Property Mapping of Multi-Component Structural Materials.” Microscopy and Microanalysis 30 (Supplement_1). https://doi.org/10.1093/mam/ozae044.278.

- Schmuck, K., M. Antenreiter, M. Alfreider, and D. Kiener. 2024. “Automatic and Time-Resolved Determination of Fracture Characteristics from in Situ Experiments.” Materials & Design 243 (July): 113038. https://doi.org/10.1016/j.matdes.2024.113038.

- Scorza, Daniela, Andrea Carpinteri, Camilla Ronchei, Andrea Zanichelli, Sabrina Vantadori, and Raimondo Lucian. 2024. “A Nonlocal Elasticity Theory to Model the Static Behaviour of Edge-Cracked Nanobeams.” Frattura Ed Integrita Strutturale 18 (67). https://doi.org/10.3221/IGF-ESIS.67.20.

- Shah, Sohail, Cameron Howard, Boopathy Kombaiah, Sriswaroop Dasari, Fei Teng, Yachun Wang, Jason Daniel, and Mukesh Bachhav. 2024. “Correlating Microstructure and Mechanical Properties of Harvested High Dose Zorita Light Water Reactor Internals.” Journal of Nuclear Materials 599 (October): 155241. https://doi.org/10.1016/j.jnucmat.2024.155241.

- Shang, Anyu, Benjamin Stegman, Kenyi Choy, Tongjun Niu, Chao Shen, Zhongxia Shang, Xuanyu Sheng, et al. 2024. “Additive Manufacturing of an Ultrastrong, Deformable Al Alloy with Nanoscale Intermetallics.” Nature Communications 15 (1): 5122. https://doi.org/10.1038/s41467-024-48693-4.

- Shen, Chao, Jin Li, Tongjun Niu, Jaehun Cho, Zhongxia Shang, Yifan Zhang, Anyu Shang, et al. 2024. “Achieving Room Temperature Plasticity in Brittle Ceramics through Elevated Temperature Preloading.” Science Advances 10 (16). https://doi.org/10.1126/sciadv.adj4079.

- Shen, Chao, Tongjun Niu, Jaehun Cho, Tianyi Sun, Anyu Shang, Yifan Zhang, Haiyan Wang, and Xinghang Zhang. 2024. “In Situ Studies on Temperature‐dependent Deformation Mechanisms of Al 2 O 3 Prepared by Spark Plasma Sintering.” Journal of the American Ceramic Society, June. https://doi.org/10.1111/jace.19964.

- Sperling, S.O., T. Bertens, J.P.M. Hoefnagels, K. van den Broek, and M.G.D. Geers. 2024. “Experimental–Numerical Analysis of Silicon Micro-Scratching.” International Journal of Solids and Structures 295 (June): 112809. https://doi.org/10.1016/j.ijsolstr.2024.112809.

- Sun, Tianyi, Tongjun Niu, Zhongxia Shang, Chao Shen, Dongyue Xie, Jian Wang, Haiyan Wang, and Xinghang Zhang. 2024. “High‐Temperature Mechanical Behavior of Single‐Crystal FeCrAl Alloy Under In Situ Micropillar Compression.” Advanced Engineering Materials 26 (21). https://doi.org/10.1002/adem.202400820.

- Supakul, Skye. 2024. “Metal/MAX Phase Multilayered Nanolaminates for Tunable Strength and Toughness: Synthesis, Microstructure, and Mechanical Properties.”

- Supakul, Skye, Manish Jain, Krishna Yaddanapudi, Jacob Gruber, Osman El-Atwani, Garritt J. Tucker, and Siddhartha Pathak. 2024. “Synthesis, Microstructure and Micro-Mechanical Characterization of Metal (Nb, Ti) – MAX Phase (Ti2AlC) Nanolaminates.” Materials Science and Engineering: A 910 (September): 146905. https://doi.org/10.1016/j.msea.2024.146905.

- Teixeira, Camila Aguiar, Subin Lee, and Christoph Kirchlechner. 2024. “Measuring the Twinning Stress at the Micron Scale: A Comprehensive Comparison of Testing Geometries.” Materials Characterization 217 (November): 114314. https://doi.org/10.1016/j.matchar.2024.114314.

- Varillas, Javier, Jaroslav Lukeš, Anastasios Manikas, Jan Maňák, Jiří Dluhoš, Zuzana Melníková, Martin Kalbáč, Costas Galiotis, and Otakar Frank. 2024. “Mechanical Response of Monolayer Graphene via a Multi-Probe Approach.” International Journal of Mechanical Sciences 273 (July): 109208. https://doi.org/10.1016/j.ijmecsci.2024.109208.

- Wang, Bokang, Tanglong Bai, Weide Wang, and Hongti Zhang. 2024. “Mechanical Properties of Silicon Nitride in Different Morphologies: In Situ Experimental Analysis of Bulk and Whisker Structures.” Materials 17 (18): 4549. https://doi.org/10.3390/ma17184549.

- Wang, Congying, Xuwei Cui, Shijun Wang, Wenlong Dong, Hai Hu, Xiaoyong Cai, Chao Jiang, Zhong Zhang, and Luqi Liu. 2024. “Anisotropic Mechanical Properties of α-MoO3 Nanosheets.” Nanoscale 16 (8). https://doi.org/10.1039/d3nr06427a.

- Wang, H., B. S. Dong, Z. B. Chen, J. Q. Liu, N. Haghdadi, R. Q. Lu, S. Primig, et al. 2024. “Effect of Compositional Heterogeneity on the Mechanical Properties of a Single-Phase Cu-9Al Alloy with Different Grain Sizes.” Acta Materialia 263. https://doi.org/10.1016/j.actamat.2023.119531.

- Wang, Liqiang, Heyi Wang, Xin Zhou, Huangliu Fu, James Utama Surjadi, Shuo Qu, Xu Song, Rong Fan, and Yang Lu. 2024. “Hierarchical Crystalline–Amorphous Nanocomposites with High Strength and Large Deformability Enabled by Elemental Diffusion.” Journal of Materials Science and Technology 171. https://doi.org/10.1016/j.jmst.2023.06.046.

- Wang, Nan, Qingping Cao, Xiaodong Wang, Shaoqing Ding, Dongxian Zhang, and Jian Zhong Jiang. 2024. “Ultra-Strong and Ductile Amorphous-Crystalline Ti-Zr-Hf-Nb-Ta/Co-Ni-V Nanolaminate Thin Films.” Journal of Alloys and Compounds 973. https://doi.org/10.1016/j.jallcom.2023.172874.

- Wang, Yachun, Cameron B. Howard, Fei Xu, Daniele Salvato, Kaustubh K. Bawane, Daniel J. Murray, David M. Frazer, et al. 2024. “Microstructural and Micromechanical Characterization of Cr Diffusion Barrier in ATR Irradiated U-10Zr Metallic Fuel.” Journal of Nuclear Materials 599 (October): 155231. https://doi.org/10.1016/j.jnucmat.2024.155231.

- Wang, Zi-Meng, Yun-Fei Jia, Jia-Dong Cai, Yuan-Yuan Cui, Xiao Li, Xian-Cheng Zhang, and Shan-Tung Tu. 2024. “Strain-Rate and Size Dependence of Gradient Lamellar Nickel Investigated by in-Situ Micropillar Compression.” Journal of Materials Research and Technology 32 (September): 3269–79. https://doi.org/10.1016/j.jmrt.2024.08.129.

- Wei, Bingqiang, Wenqian Wu, Arkajit Ghosh, Metin Kayitmazbatir, Amit Misra, and Jian Wang. 2024. “In Situ SEM Characterization of Tensile Behavior of Nano-Fibrous Al–Si and Al–Si–Sr Eutectics.” Journal of Materials Science 59 (12): 5233–46. https://doi.org/10.1007/s10853-023-09118-7.

- Weidner, Anja, Ruben Wagner, Mikhail Seleznev, and Horst Biermann. 2024. “Analysis of Detrimental Inclusions in Steel and Aluminum.” In , 645–77. https://doi.org/10.1007/978-3-031-40930-1_25.

- Wu, Yaqiao, David Estrada, and Brenden Heidrich. 2024. “Microscopy and Characterization Suite – a Facility Designed for Post-Irradiation-Examination.” Microscopy and Microanalysis 30 (Supplement_1). https://doi.org/10.1093/mam/ozae044.966.

- Wu, Yi Ling, Chung Chih Tsai, Pei Yu Chen, Jhen de You, and Chun Hway Hsueh. 2024. “Transforming Microstructures and Mechanical Properties of (CoCrNi)93-XAl7Ndx Medium Entropy Alloy Films by Annealing.” Surface and Coatings Technology 477. https://doi.org/10.1016/j.surfcoat.2023.130331.

- Xu, Hailong, Li Huang, Wen Zhang, Jing Liang, Xiaohui Lin, Xuanqiao Gao, Yanchao Li, and Jianfeng Li. 2024. “Orientation-Dependent Ion-Irradiation Responses in Molybdenum and Molybdenum-Rhenium Alloys.” Materials Letters 363. https://doi.org/10.1016/j.matlet.2024.136317.

- Yang, Bo, Pedro E. Sánchez-Jiménez, Tongjun Niu, Tianyi Sun, Zhongxia Shang, Jaehun Cho, Antonio Perejón, et al. 2024. “In Situ Study on Enhanced Plastic Deformability of Lanthanum-Doped Bismuth Ferrite Processed by Flash Sintering.” Journal of the European Ceramic Society 44 (6). https://doi.org/10.1016/j.jeurceramsoc.2023.12.099.

- Yang, Liuqing. 2024. “Exploring Surface Properties of Advanced Ni-Based Concentrated Solid-Solution Alloys by Nanomechanical Techniques.”

- Yang, Weiguang, Georg Hasemann, Ruth Schwaiger, and Manja Krüger. 2024. “Orientation-Dependent Hardness of Mo3Si Studied by Cube-Corner Nanoindentation.” Journal of Materials Science 59 (1): 277–88. https://doi.org/10.1007/s10853-023-09178-9.

- Yin, Daniel B., Haiping Sun, and Amit Misra. 2024. “Optimal Geometry for Focused Ion Beam-Milled Samples for Direct-Pull Micro-Tensile Testing Performed In Situ in a Scanning Electron Microscope.” Materials 17 (21): 5144. https://doi.org/10.3390/ma17215144.

- Zhang, Chenyun, Yurui Xing, Xuemei Song, Xue Liang, Yifeng Li, Xiaodong Lin, Hongti Zhang, and Ying Shi. 2024. “Size Effect and Plastic Deformation Mechanisms of AlON Micro/Nanopillars with Different Crystallographic Orientations.” Journal of the European Ceramic Society 44 (13): 7695–7703. https://doi.org/10.1016/j.jeurceramsoc.2024.05.010.

- Zhang, Yifan, Thomas J. Nizolek, Laurent Capolungo, Nan Li, John S. Carpenter, and Rodney J. McCabe. 2024. “Strong Interfaces: The Key to High Strength in Nano Metallic Laminates.” Acta Materialia 280 (November): 120298. https://doi.org/10.1016/j.actamat.2024.120298.

- Zhang, Zhibo, Shan Zhang, Qing Wang, Anliang Lu, Zhaoqi Chen, Ziyin Yang, Junhua Luan, Rui Su, Pengfei Guan, and Yong Yang. 2024. “Intrinsic Tensile Ductility in Strain Hardening Multiprincipal Element Metallic Glass.” Proceedings of the National Academy of Sciences 121 (18). https://doi.org/10.1073/pnas.2400200121.

- Zhou, Jingzhuo, Mengya Zhu, Ying Han, Xuefeng Zhou, Shanmin Wang, Juzheng Chen, Hao Wu, Yuan Hou, and Yang Lu. 2024. “Direct Measurement of Tensile Mechanical Properties of Few-Layer Hexagonal Boron Nitride (h-BN).” Journal of Applied Physics 135 (22). https://doi.org/10.1063/5.0209443.

- Žiberna, Katarina, Maja Koblar, Micka Bah, Franck Levassort, Goran Dražić, Hana Uršič, and Andreja Benčan. 2024. “Nanomechanical Characterization of BiFeO3 Ferroelectric Ceramics.” Journal of the European Ceramic Society 44 (12): 7025–31. https://doi.org/10.1016/j.jeurceramsoc.2024.05.011.

- Zimmerman, Jonathan, Maria Vrellou, Stefan Wagner, Astrid Pundt, Christoph Kirchlechner, and Eugen Rabkin. 2024. “Drastic Softening of Pd Nanoparticles Induced by Hydrogen Cycling.” Scripta Materialia 253 (December): 116304. https://doi.org/10.1016/j.scriptamat.2024.116304.

- Afshar-Mohajer, Mahyar, Xingwei Yang, Rong Long, and Min Zou. 2023. “3D Printing of Micro/Nano-Hierarchical Structures with Various Structural Stiffness for Controlling Friction and Deformation.” Additive Manufacturing 62. https://doi.org/10.1016/j.addma.2022.103368.

- Ahn, Seo Young, Yanbo Wang, Bozo Vazic, Robert Wheeler, and Pania Newell. 2023. “Probing the Mechanical Performance of Micro-Architected Porous Structures Through In Situ Characterization and Analysis.” JOM 75 (10): 4361–75. https://doi.org/10.1007/s11837-023-06061-5.

- Aleman, Angel Cortez. 2023. “In Situ Scanning Electron Microscopy Based Uniaxial Compression of Sub-Micrometer-Size Transition-Metal Carbide Single-Crystalline Pillars.” Los Angeles.

- Aragon, Nicole K., Ye eun Na, Phu Cuong Nguyen, Dongchan Jang, and Ill Ryu. 2023. “Micro-Beam Bending of FCC Bicrystals: A Comparison between Defect Dynamics Simulations and Experiments.” Materialia 32. https://doi.org/10.1016/j.mtla.2023.101941.

- Avadanii, Diana, Lars Hansen, Ed Darnbrough, Katharina Marquardt, David Armstrong, and Angus Wilkinson. 2023. “DIRECT TESTING OF FORSTERITE BICRYSTALS VIA In-Situ MICROPILLAR EXPERIMENTS AT 700 ° C.” https://doi.org/10.22541/essoar.167979601.17867144/v1.

- Burtscher, Michael, Markus Alfreider, Christina Kainz, and Daniel Kiener. 2023. “Deformation and Failure Behavior of Nanocrystalline WCu.” Materials Science and Engineering: A 887. https://doi.org/10.1016/j.msea.2023.145760.

- Chen, Tianyi, David Frazer, Mack Cullison, Fei Teng, Jie Lian, Kun Mo, and Fabiola Cappia. 2023. “The Effects of Radiation-Induced Grain Subdivision and Dislocations on the Fracture Properties of Uranium Dioxide.” Journal of Nuclear Materials 577. https://doi.org/10.1016/j.jnucmat.2023.154297.

- Chen, Zhuo, Yong Huang, Nikola Koutná, Zecui Gao, Davide G. Sangiovanni, Simon Fellner, Georg Haberfehlner, et al. 2023. “Large Mechanical Properties Enhancement in Ceramics through Vacancy-Mediated Unit Cell Disturbance.” Nature Communications 14 (1). https://doi.org/10.1038/s41467-023-44060-x.

- Choi, Hun Seok, Young Hwan Kim, Hyun Kyung Kim, and Kwang Bum Kim. 2023. “Assembly of Graphene-Wrapped ZIF-8 Microspheres and Confined Carbonization for Energy Storage Applications.” Journal of Power Sources 560. https://doi.org/10.1016/j.jpowsour.2023.232702.

- Chowdhury, Uraching, and Melih Eriten. 2023. “Numerical Investigation of Presliding in Viscoplastic Spherical Contacts.” Journal of Applied Mechanics, Transactions ASME 90 (6). https://doi.org/10.1115/1.4056860.

- Du, Bo, Qian Liu, Minglin He, Jiang Yi, Jing He, and Shuai Wang. 2023. “The Heterogeneous Microstructure in Laser Powder Bed Fabricated Inconel 718 Pillar and Its Influence on Mechanical Properties.” Materials Science and Engineering: A 872. https://doi.org/10.1016/j.msea.2023.144953.

- Fan, Cuncai, Shuai Pan, Xunxiang Hu, Binbin He, and Mingxin Huang. 2023. “Mechanisms of Helium Irradiation Blistering and Surface Deformation in Tungsten.” Acta Materialia 254. https://doi.org/10.1016/j.actamat.2023.118993.

- Fang, Weifeng, Zhao Mu, Yan He, Kangren Kong, Kai Jiang, Ruikang Tang, and Zhaoming Liu. 2023. “Organic–Inorganic Covalent–Ionic Molecules for Elastic Ceramic Plastic.” Nature 619 (7969). https://doi.org/10.1038/s41586-023-06117-1.

- Fedyaeva, Tatyana, Santhosh Mathesan, Anuj Bisht, Zhao Liang, Dan Mordehai, and Eugen Rabkin. 2023. “The Effects of Composition and Microstructure on Compressive Strength of Ag-Au Nanoparticles.” Acta Materialia 261. https://doi.org/10.1016/j.actamat.2023.119417.

- Gong, Mingyu, Dongyue Xie, Tianyi Sun, Xinghang Zhang, Lin Shao, and Jian Wang. 2023. “Bridging Microscale to Macroscale Mechanical Property Measurements of FeCrAl Alloys by Crystal Plasticity Modeling.” International Journal of Plasticity 165. https://doi.org/10.1016/j.ijplas.2023.103608.

- González-Nino, David. 2023. “On the Micro-Mechanical Property Characterization and Bulk-Volume Behavior Prediction of Additively Manufactured 17-4 PH Stainless Steels.”

- Gu, Ji Woo, Jae Young Bae, Guangzhe Li, Hae Won Hwang, So Hyeon Lee, Sung Geun Choi, Ju Young Kim, Myoung Ryul Ok, Yu Chan Kim, and Seung Kyun Kang. 2023. “Corrosion Characteristics of Single-Phase Mg–3Zn Alloy Thin Film for Biodegradable Electronics.” Journal of Magnesium and Alloys. https://doi.org/10.1016/j.jma.2023.06.016.

- Gupta, Richa, Sanjit Bhowmick, K. C.Hari Kumar, M. J.N.V. Prasad, and Prita Pant. 2023. “Transformation of Borides in Directionally Solidified Nickel Base Superalloy and Its Mechanical Response.” Journal of Alloys and Compounds 952. https://doi.org/10.1016/j.jallcom.2023.169996.

- Hong, Jong Dae, Daehyeok Ahn, Dongchan Jang, Hongryul Oh, Jae Yong Kim, Hyochan Kim, and Martin Ševeček. 2023. “Measurement of Local Mechanical Properties for Cr-Coated Accident Tolerant Fuel Cladding.” Journal of Nuclear Materials 579. https://doi.org/10.1016/j.jnucmat.2023.154407.

- Hu, Xuanxin, Nuohao Liu, Vrishank Jambur, Siamak Attarian, Ranran Su, Hongliang Zhang, Jianqi Xi, Hubin Luo, John Perepezko, and Izabela Szlufarska. 2023. “Amorphous Shear Bands in Crystalline Materials as Drivers of Plasticity.” Nature Materials 22 (9). https://doi.org/10.1038/s41563-023-01597-y.

- Hwang, Gyeong-Seok, Jae-Young Bae, Joon-Woo Kim, Sun-Young Park, Jeonghyun Kim, Seung-Kyun Kang, and Ju-Young Kim. 2023. “Highly Elastic and Conductive Metallic Interconnect with Crystalline–Amorphous Nanolaminate.” ACS Applied Materials & Interfaces 15 (12): 15863–71. https://doi.org/10.1021/acsami.2c22833.

- Jha, Shristy, Rajiv S. Mishra, and Sundeep Mukherjee. 2023. “Phase-Specific Damage Tolerance of a Eutectic High Entropy Alloy.” Entropy 25 (12). https://doi.org/10.3390/e25121604.

- Jha, Shristy, Saideep Muskeri, Siva Shankar Alla, and Sundeep Mukherjee. 2023. “Structural and Stress State Dependence of Small-Scale Deformation in Bulk Metallic Glass.” Journal of Alloys and Compounds 961. https://doi.org/10.1016/j.jallcom.2023.170971.

- Jha, Shristy, Abhishek Sharma, Sriswaroop Dasari, Saideep Muskeri, Rajarshi Banerjee, and Sundeep Mukherjee. 2023. “Orientation Dependent Stress-Induced Martensitic and Omega Transformations in a Refractory High Entropy Alloy.” Materialia 28. https://doi.org/10.1016/j.mtla.2023.101741.

- Jiang, H., K. P. Yu, X. C. Liu, L. H. He, B. B. He, and M. X. Huang. 2023. “Crystallography of a New Mn(V,Ti,Al)2O4 Compositionally Complex Spinel Oxide in a BCC Compositionally Complex Alloy.” Scripta Materialia 237. https://doi.org/10.1016/j.scriptamat.2023.115683.

- Juri, Afifah Z., Animesh K. Basak, and Ling Yin. 2023. “Failure Mechanisms in In-Situ SEM Micropillar Compressions of Pre-Crystallized and Crystallized Zirconia-Containing Lithium Silicate Glass-Ceramics.” Ceramics International 49 (16). https://doi.org/10.1016/j.ceramint.2023.05.261.

- Kang, Sung Gyu, Wonseok Jeong, Jeongin Paeng, Hwangsun Kim, Eunsol Lee, Gyeong Su Park, Seungwu Han, Heung Nam Han, and In Suk Choi. 2023. “E-Beam-Enhanced Solid-State Mechanical Amorphization of α-Quartz: Reduced Deformation Barrier via Localized Excess Electrons as Network Modifiers.” Materials Today 66. https://doi.org/10.1016/j.mattod.2023.04.009.

- Kim, Young Hwan, Song‐Gue Choi, Kyung Yoon Chung, Geon‐Woo Lee, Yong Gil Choi, and Kwang‐Bum Kim. 2023. “Roll‐Pressed Silicon Anodes with High Reversible Volumetric Capacity Achieved by Interfacial Stabilization and Mechanical Strengthening of a Silicon/Graphene Hybrid Assembly.” Small 19 (38). https://doi.org/10.1002/smll.202301744.

- Kong, Byeong Seo, Ji Ho Shin, Chaewon Jeong, Changheui Jang, and Sung Sik Kang. 2023. “Stability and Strengthening Effect of Aging Induced-Nanofeatures in δ-Ferrite in an Austenitic Stainless-Steel Weld.” Journal of Materials Research and Technology 23. https://doi.org/10.1016/j.jmrt.2023.02.112.

- Kumar, Azad, Chaitany Jayprakash Raorane, Asad Syed, Ali H. Bahkali, Abdallah M. Elgorban, Vinit Raj, and Seong Cheol Kim. 2023. “Synthesis of TiO2, TiO2/PAni, TiO2/PAni/GO Nanocomposites and Photodegradation of Anionic Dyes Rose Bengal and Thymol Blue in Visible Light.” Environmental Research 216. https://doi.org/10.1016/j.envres.2022.114741.

- Kwak, Dong Hyeon, Jae Min Sim, Yoon Suk Chang, Byeong Seo Kong, and Changheui Jang. 2023. “Multiscale Simulations for Estimating Mechanical Properties of Ion Irradiated 308 Based on Microstructural Features.” Nuclear Engineering and Technology 55 (8). https://doi.org/10.1016/j.net.2023.05.011.

- Lang, E. J., N. M. Heckman, T. Clark, B. Derby, A. Barrios, A. Monterrosa, C. M. Barr, et al. 2023a. “Development of an in Situ Ion Irradiation Scanning Electron Microscope.” Nuclear Instruments and Methods in Physics Research, Section B: Beam Interactions with Materials and Atoms 537. https://doi.org/10.1016/j.nimb.2023.01.016.

- Lang, E.J., N.M. Heckman, T. Clark, B. Derby, A. Barrios, A. Monterrosa, C.M. Barr, et al. 2023b. “Development of an in Situ Ion Irradiation Scanning Electron Microscope.” Nuclear Instruments and Methods in Physics Research Section B: Beam Interactions with Materials and Atoms 537 (April): 29–37. https://doi.org/10.1016/j.nimb.2023.01.016.

- Lear, C. R., M. R. Chancey, R. Flanagan, J. G. Gigax, M. T. Hoang, D. R. Jones, H. Kim, et al. 2023. “Transition in Helium Bubble Strengthening of Copper from Quasi-Static to Dynamic Deformation.” Acta Materialia 254. https://doi.org/10.1016/j.actamat.2023.118987.

- Li, Hanyu. 2023. “Micromechanistic Study of Hydrogen Embrittlement in Pipeline Steels.”

- Li, Kai, Yan Yu, Qiang Lu, Yuanfei Li, Qiao Yan, Xinyue Lan, Liya Li, Baishan Chen, and Min Song. 2023. “Microstructure and Mechanical Behavior of Quaternary Eutectic Α+θ+Q+Si Clusters in As-Cast Al-Mg-Si-Cu Alloys.” Materials 16 (18). https://doi.org/10.3390/ma16186091.

- Li, Xiaocui, You Meng, Wanpeng Li, Jun Zhang, Chaoqun Dang, Heyi Wang, Shih Wei Hung, et al. 2023a. “Multislip-Enabled Morphing of All-Inorganic Perovskites.” Nature Materials 22 (10). https://doi.org/10.1038/s41563-023-01631-z.

- Li, Xiaocui, You Meng, Wanpeng Li, Jun Zhang, Chaoqun Dang, Heyi Wang, Shih-Wei Hung, et al. 2023b. “Multislip-Enabled Morphing of All-Inorganic Perovskites.” Nature Materials 22 (10): 1175–81. https://doi.org/10.1038/s41563-023-01631-z.

- Li, Zhenkai, and Yabin Yan. 2023. “In Situ SEM Compression Study on Micro-Mechanical Behavior of Electron Beam Melted Ti-6Al-4V Alloy.” Journal of Physics: Conference Series 2553 (1): 012070. https://doi.org/10.1088/1742-6596/2553/1/012070.

- Lim, Bryan, Hansheng Chen, Zibin Chen, Nima Haghdadi, Xiaozhou Liao, Sophie Primig, Sudarsanam Suresh Babu, Andrew J. Breen, and Simon P. Ringer. 2021. “Microstructure-Property Gradients in Ni-Based Superalloy (Inconel 738) Additively Manufactured via Electron Beam Powder Bed Fusion.” Additive Manufacturing 46 (October): 102121. https://doi.org/10.1016/j.addma.2021.102121.

- Markovsky, P. E., D. G. Savvakin, O. O. Stasyuk, M. Mecklenburg, M. Pozuelo, C. Roberts, V. Ellison, and S. v. Prikhodko. 2023. “Significant Hardening Effect of High-Temperature Aging of Alloy Ti-6Al-4V Composite Reinforced with TiC.” Materials and Design 234. https://doi.org/10.1016/j.matdes.2023.112208.

- Mauseth, Tanner. 2023. “Micro-Tensile Characterization of Select TRISO-Coated Particle Layers and Interlayer Regions.”

- Mauseth, Tanner, Mary lou Dunzik-Gougar, Subhashish Meher, and Isabella J. van Rooyen. 2023. “Determining the Tensile Strength of Fuel Surrogate TRISO-Coated Particle Buffer, IPyC, and Buffer-IPyC Interlayer Regions.” Journal of Nuclear Materials 583. https://doi.org/10.1016/j.jnucmat.2023.154540.

- Meier, Timon, Runxuan Li, Stefanos Mavrikos, Brian Blankenship, Zacharias Vangelatos, M. Erden Yildizdag, and Costas P. Grigoropoulos. 2024. “Obtaining Auxetic and Isotropic Metamaterials in Counterintuitive Design Spaces: An Automated Optimization Approach and Experimental Characterization.” Npj Computational Materials 10 (1). https://doi.org/10.1038/s41524-023-01186-2.

- Meng, You, Xiaocui Li, Xiaolin Kang, Wanpeng Li, Wei Wang, Zhengxun Lai, Weijun Wang, et al. 2023. “Van Der Waals Nanomesh Electronics on Arbitrary Surfaces.” Nature Communications 14 (1). https://doi.org/10.1038/s41467-023-38090-8.

- Niu, Tongjun, Ke Xu, Chao Shen, Tianyi Sun, Justin Oberst, Carol A. Handwerker, Ganesh Subbarayan, Haiyan Wang, and Xinghang Zhang. 2023. “In Situ Study on Cu-to-Cu Thermal Compression Bonding.” Crystals 13 (7). https://doi.org/10.3390/cryst13070989.

- Orikasa, Kazue, Tyler Dolmetsch, Lihua Lou, Tony Thomas, Benjamin Boesl, and Arvind Agarwal. 2023. “Orientation-Dependent Thermal and Mechanical Properties of 2D Boron Nitride Nanoplatelet Foams via Freeze-Drying.” ACS Applied Nano Materials 6 (20): 19048–60. https://doi.org/10.1021/acsanm.3c03289.

- Pan, Bo. 2023. “Corrosion and Mechanical-Microstructural Behavior of Dissimilar Al/Steel Joints.”

- Pole, Mayur, Zexi Lu, Tanvi Anil Ajantiwalay, Matthew Olszta, Shalini Tripathi, Anqi Yu, Hardeep Mehta, et al. 2023. “Modes of Strain Accommodation in Cu-Nb Multilayered Thin Film on Indentation and Cyclic Shear.” Surfaces and Interfaces 37. https://doi.org/10.1016/j.surfin.2023.102712.

- Qiu, Keliang, Jingpeng Hou, Shuai Chen, Xiang Li, Yonghai Yue, Bo Xu, Qi Hu, et al. 2023. “Self-Healing of Fractured Diamond.” Nature Materials 22 (11). https://doi.org/10.1038/s41563-023-01656-4.

- Rudenskiy, Donat, Simone Herzog, Lutz Horbach, Nils Christian Gebhardt, Felix Weber, Anke Kaletsch, and Christoph Broeckmann. 2023a. “Numerical Modeling of Residual Stresses and Fracture Strengths of Ba0.5Sr0.5Co0.8Fe0.2O3−δ in Reactive Air Brazed Joints.” Materials 16 (23). https://doi.org/10.3390/ma16237265.

- 2023b. “Numerical Modeling of Residual Stresses and Fracture Strengths of Ba0.5Sr0.5Co0.8Fe0.2O3−δ in Reactive Air Brazed Joints.” Materials 16 (23): 7265. https://doi.org/10.3390/ma16237265.

- Sharma, Amit, Oz Mendelsohn, Anuj Bisht, Johann Michler, Raj Kiran Koju, Yuri Mishin, and Eugen Rabkin. 2023. “Solid-Solution and Precipitation Softening Effects in Defect-Free Faceted Nickel-Iron Nanoparticles.” Acta Materialia 243. https://doi.org/10.1016/j.actamat.2022.118527.

- Shi, Qianqian, Dashen Dong, Gediminas Gervinskas, Han Lin, Debabrata Sikdar, Baohua Jia, Sumeet Walia, et al. 2023. “Soft Plasmene Helical Nanostructures.” Advanced Materials Technologies 8 (9). https://doi.org/10.1002/admt.202201866.

- Tom Bertens. 2023. “Toward Understanding Wear Particle Generation on Silicon Wafers.”

- Vangelatos, Zacharias, M. Erden Yildizdag, and Costas P. Grigoropoulos. 2023. “A Designer’s Challenge: Unraveling the Architected Structure of Deep Sea Sponges for Lattice Mechanical Metamaterials.” Extreme Mechanics Letters 61. https://doi.org/10.1016/j.eml.2023.102013.

- Vo, H. T., D. Frazer, A. A. Kohnert, S. Teysseyre, S. Fensin, and P. Hosemann. 2023. “Role of Low-Level Void Swelling on Plasticity and Failure in a 33 Dpa Neutron-Irradiated 304 Stainless Steel.” International Journal of Plasticity 164. https://doi.org/10.1016/j.ijplas.2023.103577.

- Vo, H. T., S. Pal, N. Almirall, S. Tumey, G. R. Odette, S. A. Maloy, and P. Hosemann. 2023. “Dose and Dose Rate Effects on the Microstructural and Mechanical Stability of Long-Range Ordered Precipitates in Inconel 718.” Materials Science and Engineering: A 870. https://doi.org/10.1016/j.msea.2023.144916.

- Vu, Quy Tung Linh, Guillaume Seon, Sarvenaz Ghaffari, Andrew Makeev, Frédéric Lachaud, Miguel Charlotte, and Yves Gourinat. 2023. “Evaluating Residual Stress in Carbon Fiber-Reinforced Polymer (CFRP) at Microscale Using Fiber Push-Out Experiment and Finite Element Modeling.” Polymers 15 (12). https://doi.org/10.3390/polym15122596.

- W. Luo, C. Gasper, S. Zhang, P. L. Sun, N. Ulumuddin, A. Petrova, Y. Lysogorskiy, R. Drautz, Z. Xie, S. Korte-Kerzel. 2023. “Origins of Limited Non-Basal Plasticity in the μ-Phase at Room Temperature.”

- Wang, Bo, Kyoko Kaede, Sadahiro Tsurekawa, and Katerina E. Aifantis. 2023. “Capturing the Softening in T91 Steel Annealed with Molten LBE through Interfacial Gradient Plasticity.” Materials Today Communications 35. https://doi.org/10.1016/j.mtcomm.2023.105719.

- Wang, Nan, Qingping Cao, Xiaodong Wang, Shaoqing Ding, Dongxian Zhang, and Jian Zhong Jiang. 2023. “Fluence- and Thickness-Dependent Microstructure Evolutions in Ti-Zr-Hf-Nb-Ta High Entropy Alloy Thin Films.” Journal of Alloys and Compounds 953. https://doi.org/10.1016/j.jallcom.2023.170069.

- Wang, Xin, Baolong Zheng, Hangman Chen, Dongxu Liu, Kehang Yu, Benjamin E. MacDonald, Lorenzo Valdevit, et al. 2023. “Deformation Behavior of Cell Walls in an Additively Manufactured Hybrid Metallic Foam.” Additive Manufacturing 61. https://doi.org/10.1016/j.addma.2022.103365.

- Wang, Yuecun, Lin Tian, Meng Li, and Zhiwei Shan. 2023. “Significant ‘Smaller Is Softer’ in Amorphous Silicon via Irradiation-Mediated Surface Modification.” Journal of Materials Science and Technology 166. https://doi.org/10.1016/j.jmst.2023.04.062.

- Wang, Zi Meng, Yun Fei Jia, Kai Shang Li, Yong Zhang, Jia Dong Cai, Xian Cheng Zhang, Hiroyuki Hirakata, and Shan Tung Tu. 2023. “Lamellar Aspect-Ratio and Thickness-Dependent Strength-Ductility Synergy in Pure Nickel during in-Situ Micro-Tensile Loading.” Journal of Materials Science and Technology 157. https://doi.org/10.1016/j.jmst.2023.01.037.

- Wei, Bingqiang, Wenqian Wu, and Jian Wang. 2023. “In-Situ Investigation of Tension-Compression Asymmetry of Ni-SiOC Nanocomposites.” Scripta Materialia 223. https://doi.org/10.1016/j.scriptamat.2022.115103.

- Wu, Yiming, Chang Zhou, Rui Wu, Lixin Sun, Chenyang Lu, Yunzhen Xiao, Zhengxiong Su, et al. 2023. “Synergistic Strengthening of Al–SiC Composites by Nano-Spaced SiC-Nanowires and the Induced High-Density Stacking Faults.” Composites Part B: Engineering 250. https://doi.org/10.1016/j.compositesb.2022.110458.

- Yang, Guang, Dongxue Xie, Yizhou Nie, Xuedong Zhai, Nesredin Kedir, Weinong Chen, A. P. S. Gaur, et al. 2023. “In-Situ X-Ray Imaging High Strain Rate Compression of Laminate Al-Graphene Composite and Mechanical Property Characterization.” JOM 75 (8): 3105–10. https://doi.org/10.1007/s11837-023-05853-z.

- Zhang, Xuan, and Xiaoyan Li. 2023. “Scaling Effect of Dry Adhesion for Microfibrils and Transition Size to Flaw Insensitivity.” Journal of Applied Mechanics, Transactions ASME 90 (12). https://doi.org/10.1115/1.4062884.

- Zhang, Yifan, Thomas J. Nizolek, Laurent Capolungo, Nan Li, John S. Carpenter, and Rodney J. McCabe. 2023. “The Effect of Annealing on Kink Band Formation in Ag/Fe Nanolaminates.” Scripta Materialia 235. https://doi.org/10.1016/j.scriptamat.2023.115623.

- Zhang, Yifan, Miroslav Zecevic, Aritra Chakraborty, Rodney J. McCabe, Thomas J. Nizolek, Ricardo A. Lebensohn, John S. Carpenter, Nan Li, and Laurent Capolungo. 2023a. “Unraveling Kinking: A Plasticity Enhancing Failure Mode in High Strength Nano Metallic Laminates.” Acta Materialia 260. https://doi.org/10.1016/j.actamat.2023.119342.

- 2023b. “Unraveling Kinking: A Plasticity Enhancing Failure Mode in High Strength Nano Metallic Laminates.” Acta Materialia 260 (November): 119342. https://doi.org/10.1016/j.actamat.2023.119342.

- Zhang, Yinxia, Matthias Bartosik, Steffen Brinckmann, Subin Lee, and Christoph Kirchlechner. 2023. “Direct Observation of Crack Arrest after Bridge Notch Failure: A Strategy to Increase Statistics and Reduce FIB-Artifacts in Micro-Cantilever Testing.” Materials and Design 233. https://doi.org/10.1016/j.matdes.2023.112188.

- Zhang, Zhaolu, Zhufang Yang, and Guangyu He. 2023. “Alleviating the Adverse Influence of Nitride Coating on the Fatigue Performance of Ti6Al4V by Ni Alloying.” Journal of Materials Research and Technology 26. https://doi.org/10.1016/j.jmrt.2023.07.218.

- Zhu, Mengya, Jingzhuo Zhou, Zezhou He, Yang Zhang, Hao Wu, Juzheng Chen, Yinbo Zhu, Yuan Hou, Hengan Wu, and Yang Lu. 2023. “Ductile Amorphous Boron Nitride Microribbons.” Materials Horizons 10 (11). https://doi.org/10.1039/d3mh00845b.

- Žiberna, Katarina, Matej Šadl, Aljaž Drnovšek, Goran Dražić, Hana Uršič, and Andreja Benčan. 2023. “Influence of Thermal Treatment on the Cross-Sectional Properties of Aerosol-Deposited Pb(Mg1/3Nb2/3)O3−PbTiO3 Thick Films.” Crystals 13 (3). https://doi.org/10.3390/cryst13030536.

- Afshar-Mohajer, Mahyar, Xingwei Yang, Rong Long, and Min Zou. 2022. “Understanding the Friction and Deformation Behavior of Micro/Nano-Hierarchical Textures through in-Situ SEM Observation and Mechanics Modeling.” Tribology International 165. https://doi.org/10.1016/j.triboint.2021.107271.

- Ajantiwalay, Tanvi, Richard Michi, Christian Roach, Amit Shyam, Alex Plotkowski, and Arun Devaraj. 2022. “Influence of Microstructural Heterogeneities on Small-Scale Mechanical Properties of an Additively Manufactured Al-Ce-Ni-Mn Alloy.” Additive Manufacturing Letters 3. https://doi.org/10.1016/j.addlet.2022.100092.

- Almog, Ehud, Amit Sharma, Yuanshen Qi, Jonathan Zimmerman, and Eugen Rabkin. 2022. “Hybrid Hierarchical Nanolattices with Porous Platinum Coating.” Acta Materialia 225. https://doi.org/10.1016/j.actamat.2021.117552.

- Bai, Lichen, Bingqiang Wei, Jing Wang, Kaisheng Ming, Shijian Zheng, and Jian Wang. 2022. “High Strength and Thermal Stability of Core-Shell Fe-SiOC Nanocolumnar Composites.” Scripta Materialia 219. https://doi.org/10.1016/j.scriptamat.2022.114885.

- Bhowmick, Sanjit, and Eric Hintsala. 2022. “Mechanical Properties of Bond Coatings and Ni-Based Superalloys at Extreme Temperatures.” Microscopy and Microanalysis 28 (S1). https://doi.org/10.1017/s1431927622007152.

- Buchwalder, Anja, Jan Böcker, Eugen Hegelmann, Anne Jung, Martin Michler, and Volker Klemm. 2022. “Investigations on the Influence of Subsequent Electron Beam (EB) Remelting on the Microstructure of an Aluminium Nitride Layer Formed on an Aluminium Substrate (Part II).” Coatings 12 (5). https://doi.org/10.3390/coatings12050650.

- Buchwalder, Anja, Jan Böcker, Eugen Hegelmann, and Volker Klemm. 2022. “Investigations on the Microstructure of an Aluminium Nitride Layer and Its Interface with the Aluminium Substrate (Part I).” Coatings 12 (5). https://doi.org/10.3390/coatings12050618.

- Budiman, Arief Suriadi. 2022a. “Extreme Mechanics in Advanced, Emerging Materials.” In , 5–61. https://doi.org/10.1007/978-981-15-6720-9_2.

- 2022b. Principles of Extreme Mechanics (XM) in Design for Reliability (DfR). Singapore: Springer Singapore. https://doi.org/10.1007/978-981-15-6720-9.

- Burtscher, Michael, Markus Alfreider, Christina Kainz, Klemens Schmuck, and Daniel Kiener. 2022. “In Situ Micromechanical Analysis of a Nano-Crystalline W-Cu Composite.” Materials and Design 220. https://doi.org/10.1016/j.matdes.2022.110848.

- Cheng, Justin Y., Shuozhi Xu, Youxing Chen, Zezhou Li, Jon K. Baldwin, Irene J. Beyerlein, and Nathan A. Mara. 2022. “Simultaneous High-Strength and Deformable Nanolaminates With Thick Biphase Interfaces.” Nano Letters 22 (5): 1897–1904. https://doi.org/10.1021/acs.nanolett.1c04144.

- Cuncai Fan. 2022. “Radiation Response of Nanostructured Cu.”

- DelRio, Frank, Scott Grutzik, William Mook, Sara Dickens, Paul Kotula, Eric Hintsala, Douglas Stauffer, and Brad Boyce. 2022. “In-Situ, Nanoscale Fracture Toughness Measurements for Improved Mechanical Interfaces.” Albuquerque, NM, and Livermore, CA (United States). https://doi.org/10.2172/1885209.

- DelRio, Frank W., Scott J. Grutzik, William M. Mook, Sara M. Dickens, Paul G. Kotula, Eric D. Hintsala, Douglas D. Stauffer, and Brad L. Boyce. 2022. “Eliciting Stable Nanoscale Fracture in Single-Crystal Silicon.” Materials Research Letters 10 (11): 728–35. https://doi.org/10.1080/21663831.2022.2088251.

- Dickens, Sara M, Frank W DelRio, Scott J Grutzik, William M Mook, Brad L Boyce, Eric Hintsala, Douglas Stauffer, and Robert F Cook. 2022. “ In-Situ Fracture Toughness of Single Crystal Silicon Double-Cantilever Beams .” Microscopy and Microanalysis 28 (S1). https://doi.org/10.1017/s1431927622000964.

- Eom, Hyun Joon, Ji Ho Shin, Byeong Seo Kong, Chaewon Jeong, Changheui Jang, Daehyeok Ahn, and Dongchan Jang. 2022. “Dissolution of Nanosized NbC Precipitates in Austenite Matrix during Elastic Deformation - Deleterious Effect of High Number Density.” Materials Science and Engineering: A 833. https://doi.org/10.1016/j.msea.2021.142506.

- Escobar, Julian, Bharat Gwalani, Matthew Olszta, Joshua Silverstein, Tanvi Ajantiwalay, Nicole Overman, Wenkai Fu, et al. 2022. “Heterogenous Activation of Dynamic Recrystallization and Twinning during Friction Stir Processing of a Cu-4Nb Alloy.” Journal of Alloys and Compounds 928. https://doi.org/10.1016/j.jallcom.2022.167007.

- Escobar, Julian, Bharat Gwalani, Joshua Silverstein, Tanvi Ajantiwalay, Christian Roach, Luciano Bergmann, Jorge F. dos Santos, Emad Maawad, Benjamin Klusemann, and Arun Devaraj. 2023. “Rapid Grain Refinement and Compositional Homogenization in a Cast Binary Cu50Ni Alloy Achieved by Friction Stir Processing.” Materials Characterization 202. https://doi.org/10.1016/j.matchar.2023.112999.

- Feng, Chuangshi, Xiaobin Feng, Zhou Guan, Hongquan Song, Tian-Li Wang, WeiBing Liao, Yang Lu, and Fuxiang Zhang. 2022a. “Nanocrystalline (AlTiVCr)N High Entropy Nitride Thin Films with Superior Performance.” SSRN Electronic Journal. https://doi.org/10.2139/ssrn.4060855.

- Feng, Chuangshi, Xiaobin Feng, Zhou Guan, Hongquan Song, Tianli Wang, Weibing Liao, Yang Lu, and Fuxiang Zhang. 2022b. “Nanocrystalline (AlTiVCr)N Multi-Component Nitride Thin Films with Superior Mechanical Performance.” Nanomaterials 12 (15). https://doi.org/10.3390/nano12152722.

- Feng, Shizhe, Ke Cao, Yue Gao, Ying Han, Zhanli Liu, Yang Lu, and Zhiping Xu. 2022. “Experimentally Measuring Weak Fracture Toughness Anisotropy in Graphene.” Communications Materials 3 (1). https://doi.org/10.1038/s43246-022-00252-4.

- Frazer, D., F. Cappia, B. Miller, D. Murray, A. Winston, A. Pomo, and J. T. White. 2022. “Nanoindentation Testing of High Burn-up Fast Reactor Mixed Oxide Fuel.” Journal of Nuclear Materials 564. https://doi.org/10.1016/j.jnucmat.2022.153668.

- Frazer, D., F. Teng, D. Murray, A. Pomo, A. Winston, J. I. Cole, J. F. Jue, and J. Giglio. 2022. “Micro-Tensile Testing of the Bond Line in Hot Isostatic Pressed Aluminum.” Journal of Nuclear Materials 561. https://doi.org/10.1016/j.jnucmat.2022.153532.

- Fuger, C., R. Hahn, L. Zauner, T. Wojcik, M. Weiss, A. Limbeck, O. Hunold, P. Polcik, and H. Riedl. 2022. “Anisotropic Super-Hardness of Hexagonal WB 2± z Thin Films.” Materials Research Letters 10 (2): 70–77. https://doi.org/10.1080/21663831.2021.2021308.

- Gao, Peng, Shuo Sun, Heng Li, Ranming Niu, Shuang Han, Hongxiang Zong, Hao Wang, Jianshe Lian, and Xiaozhou Liao. 2022. “Ultra-Strong and Thermally Stable Nanocrystalline CrCoNi Alloy.” Journal of Materials Science and Technology 106. https://doi.org/10.1016/j.jmst.2021.08.009.

- Ghaffarian, Hadi, Ye Eun Na, and Dongchan Jang. 2022. “Interfacial Plasticity Mediated by Lath Boundaries in Reduced-Activation Ferritic/Martensitic Steels.” Journal of Nuclear Materials 559. https://doi.org/10.1016/j.jnucmat.2021.153439.

- Guo, Huixia, Qinshuo Sun, Dapeng Zhou, Miao Yu, Yongxin Wang, Qiong Wang, and Xiaojing Li. 2022. “Erosion Behavior of CrN, CrAlN and CrAlN/CrN Multilayer Coatings Deposited on Ti6Al4V.” Surface and Coatings Technology 437. https://doi.org/10.1016/j.surfcoat.2022.128284.

- Gwalani, Bharat, Qin Pang, Anqi Yu, Wenkai Fu, Lei Li, Mayur Pole, Christian Roach, et al. 2022. “Extended Shear Deformation of the Immiscible Cu–Nb Alloy Resulting in Nanostructuring and Oxygen Ingress with Enhancement in Mechanical Properties.” ACS Omega 7 (16): 13721–36. https://doi.org/10.1021/acsomega.1c07368.

- Heyn, W., S. Ananiev, H. Melzner, K. Goller, J. Zechner, A. Clausner, and E. Zschech. 2023. “Micromechanical Adhesion Experiments and Simulation on Cu-Damascene Processed Test Devices.” IEEE Transactions on Device and Materials Reliability 23 (1). https://doi.org/10.1109/TDMR.2022.3232023.

- Hosemann, Peter, Assel Aitkaliyeva, Laurent Capolungo, Eric Olivas, Andrew Dong, and Jonathan Giggax. 2022. “Bridging the Length Scales on Mechanical Property Evaluation (Final Report).” Idaho Falls, ID (United States). https://doi.org/10.2172/1907269.

- Huang, L., P. Huang, and F. Wang. 2022. “Excellent Work-Hardening in ZrCu/NiNb Amorphous/Amorphous Nanolaminates.” Materials Science and Engineering: A 831 (January): 142277. https://doi.org/10.1016/j.msea.2021.142277.

- Jayaram, Vikram. 2022. “Small-Scale Mechanical Testing.” Annual Review of Materials Research 52 (1): 473–523. https://doi.org/10.1146/annurev-matsci-080819-123640.

- Jeon, Eunyoung, Jeon Min Kang, Ga‐Hyun Bae, Chu Hui Zeng, Seungyong Shin, Byeongdu Lee, Wooram Park, Jung‐Hoon Park, and Joonseok Lee. 2022. “Flexible 3D Nanonetworked Silica Film as a Polymer‐Free Drug‐Eluting Stent Platform to Effectively Suppress Tissue Hyperplasia in Rat Esophagus.” Advanced Healthcare Materials 11 (14). https://doi.org/10.1002/adhm.202200389.

- Jiang, Shuimiao, Lichen Bai, Qi An, Zhe Yan, Weiming Li, Kaisheng Ming, and Shijian Zheng. 2022. “Dependence of Plastic Stability on 3D Interface Layer in Nanolaminated Materials.” Acta Metallurgica Sinica (English Letters) 35 (11): 1759–64. https://doi.org/10.1007/s40195-022-01425-3.

- Juan, Jose M.San, Jose F. Gómez-Cortés, and María L. Nó. 2022. “Ultra-High Mechanical Damping during Superelastic Bending of Micro Pillars and Micro Beams in Cu-Al-Ni Shape Memory Alloys.” Journal of Alloys and Compounds 929. https://doi.org/10.1016/j.jallcom.2022.167307.

- Juri, Afifah Z., Animesh K. Basak, and Ling Yin. 2022a. “In-Situ SEM Cyclic Nanoindentation of Pre-Sintered and Sintered Zirconia Materials.” Journal of the Mechanical Behavior of Biomedical Materials 126. https://doi.org/10.1016/j.jmbbm.2021.105068.

- 2022b. “In-Situ SEM Micropillar Compression of Porous and Dense Zirconia Materials.” Journal of the Mechanical Behavior of Biomedical Materials 132. https://doi.org/10.1016/j.jmbbm.2022.105268.

- Juri, Afifah Zakiyyah. 2022. “In-Situ Micro and Nanomechanical Characterization and Ultrasonic Machining of Zirconia Ceramics.”

- Kang, Sung Gyu, Kyeongjae Jeong, Jeongin Paeng, Wonseok Jeong, Seungwu Han, Jae Pyeong Ahn, Steven Boles, Heung Nam Han, and In Suk Choi. 2022. “Athermal Glass Work at the Nanoscale: Engineered Electron-Beam-Induced Viscoplasticity for Mechanical Shaping of Brittle Amorphous Silica.” Acta Materialia 238. https://doi.org/10.1016/j.actamat.2022.118203.

- Kim, Na Hyang, Gyeong Seok Hwang, Hangeul Kim, Si Hoon Kim, Jeong Hyun Woo, Myoung Hoon Song, and Ju Young Kim. 2022. “Enhanced Biaxial Stretchability of Wrinkled SiO2 Thin Films for Stretchable Encapsulation.” Scripta Materialia 207. https://doi.org/10.1016/j.scriptamat.2021.114280.

- Kim, Young Hwan, Geon‐Woo Lee, Yeon Jun Choi, Hun Seok Choi, and Kwang‐Bum Kim. 2022. “Mechanically Resilient Graphene Assembly Microspheres with Interlocked N‐Doped Graphene Nanostructures Grown In Situ for Highly Stable Lithium Metal Anodes.” Advanced Functional Materials 32 (25). https://doi.org/10.1002/adfm.202113316.

- Ko, Ping Hsu, Ya Jing Lee, and Shou Yi Chang. 2022. “Microstructure and Mechanical Properties of Intergranular Boride Precipitation-Toughened HfMoNbTaTiZr Refractory High-Entropy Alloy.” Materials 15 (19). https://doi.org/10.3390/ma15196666.

- Lear, C. R., J. G. Gigax, O. el Atwani, M. R. Chancey, H. Kim, N. Li, Y. Wang, and S. J. Fensin. 2022. “Effects of Helium Cavity Size and Morphology on the Strength of Pure Titanium.” Scripta Materialia 212. https://doi.org/10.1016/j.scriptamat.2022.114531.

- Lee, Gun‐Hee, Heejin Woo, Chanwoong Yoon, Congqi Yang, Jae‐Young Bae, Wonsik Kim, Do Hoon Lee, et al. 2022. “A Personalized Electronic Tattoo for Healthcare Realized by On‐the‐Spot Assembly of an Intrinsically Conductive and Durable Liquid‐Metal Composite.” Advanced Materials 34 (32). https://doi.org/10.1002/adma.202204159.

- Lee, Hyunhwan, Seungwan Kim, Wonsik Kim, Seung Mo Kang, Yun Hyeok Kim, Junho Jang, Seung Min Han, and Byeong Soo Bae. 2022. “Highly Transparent and Resilient Urethane-Methacrylate Siloxane Composite for Hard, yet Stretchable Protective Coating.” Progress in Organic Coatings 162. https://doi.org/10.1016/j.porgcoat.2021.106567.

- Li, Yanxiao. 2022. “Multifunctional Behaviors of Two-Dimensional Materials and Their Composites.”

- Liu, Chang, Wenjun Lu, Wenzhen Xia, Chaowei Du, Ziyuan Rao, James P. Best, Steffen Brinckmann, et al. 2022. “Massive Interstitial Solid Solution Alloys Achieve Near-Theoretical Strength.” Nature Communications 13 (1). https://doi.org/10.1038/s41467-022-28706-w.

- Liu, Ying, Xiangyuan Cui, Ranming Niu, Shujun Zhang, Xiaozhou Liao, Scott D. Moss, Peter Finkel, Magnus Garbrecht, Simon P. Ringer, and Julie M. Cairney. 2022. “Giant Room Temperature Compression and Bending in Ferroelectric Oxide Pillars.” Nature Communications 13 (1). https://doi.org/10.1038/s41467-022-27952-2.

- Michas, Christos, M. Çağatay Karakan, Pranjal Nautiyal, Jonathan G. Seidman, Christine E. Seidman, Arvind Agarwal, Kamil Ekinci, Jeroen Eyckmans, Alice E. White, and Christopher S. Chen. 2022. “Engineering a Living Cardiac Pump on a Chip Using High-Precision Fabrication.” Science Advances 8 (16). https://doi.org/10.1126/sciadv.abm3791.

- Ming, Kaisheng, Zhengwang Zhu, Wenqing Zhu, Ben Fang, Bingqiang Wei, Peter K. Liaw, Xiaoding Wei, Jian Wang, and Shijian Zheng. 2022. “Enhancing Strength and Ductility via Crystalline-Amorphous Nanoarchitectures in TiZr-Based Alloys.” Science Advances 8 (10). https://doi.org/10.1126/sciadv.abm2884.

- Nautiyal, Pranjal, Jenniffer Bustillos, Tamil Selvam, Cheng Zhang, Sudipta Seal, Benjamin Boesl, and Arvind Agarwal. 2022. “In Situ Investigation of Deformation Mechanisms Induced by Boron Nitride Nanotubes and Nanointerphases in Ti–6Al–4V Alloy.” Advanced Engineering Materials 24 (12). https://doi.org/10.1002/adem.202200610.

- Neuber, Nico, Maryam Sadeghilaridjani, Nandita Ghodki, Oliver Gross, Bastian Adam, Lucas Ruschel, Maximilian Frey, et al. 2022. “Effect of Composition and Thermal History on Deformation Behavior and Cluster Connections in Model Bulk Metallic Glasses.” Scientific Reports 12 (1). https://doi.org/10.1038/s41598-022-20938-6.

- Pozuelo, Marta, and Jaime Marian. 2022. “Microscale Deformation Controlled by Compositional Fluctuations in Equiatomic Nb–Mo–Ta–W Alloys.” Materials Science and Engineering: A 856. https://doi.org/10.1016/j.msea.2022.143892.

- Radchenko, Ihor, Wenxin Zhu, Liu Qing, Etienne Navarro, Rahul Sahay, Pooi See Lee, Nagarajan Raghavan, Olivier Thomas, Arief Suriadi Budiman, and Kai Chen. 2022. “Interface Rotation in Cu/Nb Accumulative Roll Bonded (ARB) Nanolaminates.” SSRN Electronic Journal. https://doi.org/10.2139/ssrn.4101121.

- Roscioli, Gianluca, Matej Repka, Stella Pedrazzini, and Cemal Cem Tasan. 2022. “Chemo-Mechanical Effects on the Cutting-Induced Mixed-Mode II-III Fracture of Martensitic Stainless Steels: An in-Situ Investigation.” Acta Materialia 231. https://doi.org/10.1016/j.actamat.2022.117803.

- Schmalbach, Kevin Michael. 2022. “Temperature and Rate Effects on the Mechanical Behavior of Tungsten and Its Nanocomposites.”

- Sheikh, Haris Moazam. 2022. “Mixed-Variable Multi-Objective Bayesian Optimization, Design-By-Morphing and Their Applications.” Berkeley.

- Sheikh, Haris Moazam, Timon Meier, Brian Blankenship, Zacharias Vangelatos, Naichen Zhao, Philip S. Marcus, and Costas P. Grigoropoulos. 2022. “Systematic Design of Cauchy Symmetric Structures through Bayesian Optimization.” International Journal of Mechanical Sciences 236. https://doi.org/10.1016/j.ijmecsci.2022.107741.

- Shi, Huaiyu, Xiangjun Wu, Shiyang Sun, Chenyan Wang, Zacharias Vangelatos, Ariel Ash-Shakoor, Costas P. Grigoropoulos, Patrick T. Mather, James H. Henderson, and Zhen Ma. 2022. “Profiling the Responsiveness of Focal Adhesions of Human Cardiomyocytes to Extracellular Dynamic Nano-Topography.” Bioactive Materials 10. https://doi.org/10.1016/j.bioactmat.2021.08.028.

- Shiau, Ching Heng, Miguel Pena, Yongchang Li, Sisi Xiang, Cheng Sun, Michael D. McMurtrey, and Lin Shao. 2022. “Micropillar Compression of Additively Manufactured 316L Stainless Steels after 2 MeV Proton Irradiation: A Comparison Study between Planar and Cross-Sectional Micropillars.” Metals 12 (11). https://doi.org/10.3390/met12111843.

- Sun, Tianyi, Jaehun Cho, Zhongxia Shang, Tongjun Niu, Jie Ding, Jian Wang, Haiyan Wang, and Xinghang Zhang. 2022. “Deformation Mechanism in Nanolaminate FeCrAl Alloys by in Situ Micromechanical Strain Rate Jump Tests at Elevated Temperatures.” Scripta Materialia 215. https://doi.org/10.1016/j.scriptamat.2022.114698.

- Tianyi Sun. 2022. “Radiation Response and Mechanical Properties of FeCrAl Alloy.”

- Tongjun Niu. 2022. “Microstructure Evolution and Mechanical Behaviors of Triphase Immiscible Nanocomposites Under Extreme Environments.”

- Tsianikas, S. J., Y. Chen, J. Jeong, S. Zhang, and Z. Xie. 2022. “Forging Strength–Ductility Unity in a High Entropy Steel.” Journal of Materials Science and Technology 113. https://doi.org/10.1016/j.jmst.2021.10.019.

- Tsianikas, Simon, Yujie Chen, Ashley Slattery, Jonathan Peters, and Zonghan Xie. 2022. “Adaptive Attenuation of Hierarchical Composition Fluctuations Augments the Plastic Strain of a High Entropy Steel.” Materials Science and Engineering: A 857. https://doi.org/10.1016/j.msea.2022.144037.

- Wagner, Ruben, Robert Lehnert, Enrico Storti, Lisa Ditscherlein, Christina Schröder, Steffen Dudczig, Urs A. Peuker, et al. 2022. “Nanoindentation of Alumina and Multiphase Inclusions in 42CrMo4 Steel.” Materials Characterization 193. https://doi.org/10.1016/j.matchar.2022.112257.

- WANG, BO, Kyoko Kaede, Sadahiro Tsurekawa, and Katerina E. Aifantis. 2022. “Capturing the Softening in T91-Lbe Steel Micropillars Through Mechanical Interface Energy Terms.” SSRN Electronic Journal. https://doi.org/10.2139/ssrn.4122106.

- Wang, H., Q. Chao, X. Y. Cui, Z. B. Chen, A. J. Breen, M. Cabral, N. Haghdadi, et al. 2022. “Introducing C Phase in Additively Manufactured Ti-6Al-4V: A New Oxygen-Stabilized Face-Centred Cubic Solid Solution with Improved Mechanical Properties.” Materials Today 61. https://doi.org/10.1016/j.mattod.2022.10.026.

- Wang, Nan, Qingping Cao, Xiaodong Wang, Shaoqing Ding, Dongxian Zhang, and Jian Zhong Jiang. 2022a. “Ultrahigh Specific Hardness of Co-Ni-V-Al Medium Entropy Alloy Thin Films.” Materials Today Communications 31. https://doi.org/10.1016/j.mtcomm.2022.103447.

- 2022b. “Unusual Deformation-Induced Martensitic Transformation in Fe-Co-Ni-Cr-Mn High Entropy Alloy Thin Films.” Journal of Alloys and Compounds 920. https://doi.org/10.1016/j.jallcom.2022.165959.

- Wang, Tianyu, Yue Chen, Ailian Chen, and Yang Chen. 2022. “Development of Carbon Sphere/Ceria (CS/CeO2) Heterostructured Particles and Their Applications to Functional Abrasives toward Photochemical Mechanical Polishing.” Applied Surface Science 593. https://doi.org/10.1016/j.apsusc.2022.153449.

- Wang, Yachun, David M. Frazer, Fabiola Cappia, Fei Teng, Daniel J. Murray, Tiankai Yao, Colin D. Judge, Jason M. Harp, and Luca Capriotti. 2022. “Small-Scale Mechanical Testing and Characterization of Fuel Cladding Chemical Interaction between HT9 Cladding and Advanced U-Based Metallic Fuel Alloy.” Journal of Nuclear Materials 566. https://doi.org/10.1016/j.jnucmat.2022.153754.

- Wang, Yachun, Xiang Liu, Daniel J. Murray, Fei Teng, Wen Jiang, Mukesh Bachhav, Laura Hawkins, et al. 2022. “Measurement of Grain Boundary Strength of Inconel X-750 Superalloy Using in-Situ Micro-Tensile Testing Techniques in FIB/SEM System.” Materials Science and Engineering: A 849. https://doi.org/10.1016/j.msea.2022.143475.

- Wang, Zimeng, Yunfei Jia, Yong Zhang, Pei Tang, Xiancheng Zhang, and Shantung Tu. 2022. “Achieving High Strength-Plasticity of Nanoscale Lamellar Grain Extracted from Gradient Lamellar Nickel.” Chinese Journal of Mechanical Engineering 35 (1): 58. https://doi.org/10.1186/s10033-022-00738-9.

- Wei, Bingqiang, Wenqian Wu, Michae1 Nastasi, Lin Li, and Jian Wang. 2022. “Plastic Flow Behaviors of High-Strength Dual-Phase Ni-SiOC Nanocomposites.” International Journal of Plasticity 158. https://doi.org/10.1016/j.ijplas.2022.103431.

- Wei, Shaolou, Jinwoo Kim, and Cemal Cem Tasan. 2022. “In-Situ Investigation of Plasticity in a Ti-Al-V-Fe (Α+β) Alloy: Slip Mechanisms, Strain Localization, and Partitioning.” International Journal of Plasticity 148. https://doi.org/10.1016/j.ijplas.2021.103131.

- Woo, Jeong-Hyun, Sun-Young Park, Donghwan Koo, Myoung Hoon Song, Hyesung Park, and Ju-Young Kim. 2022. “Highly Elastic and Corrosion-Resistive Metallic Glass Thin Films for Flexible Encapsulation.” ACS Applied Materials & Interfaces 14 (4): 5578–85. https://doi.org/10.1021/acsami.1c20551.

- Wu, Fan, Siyu Qiang, Xiaohua Zhang, Fei Wang, Xia Yin, Lifang Liu, Jianyong Yu, Yi‐Tao Liu, and Bin Ding. 2022. “The Rising of Flexible and Elastic Ceramic Fiber Materials: Fundamental Concept, Design Principle, and Toughening Mechanism.” Advanced Functional Materials 32 (45). https://doi.org/10.1002/adfm.202207130.

- Wu, Jing, Sirong Lu, Ruirun Chen, and Yu Lung Chiu. 2022. “In-Situ Deformation and the Size-Dependent Yielding Behaviour of Mg24Y5.” Materials Science and Engineering: A 835. https://doi.org/10.1016/j.msea.2022.142633.

- Wu, Shenghua, Hanne S. Soreide, Bin Chen, Jianjun Bian, Chong Yang, Chunan Li, Peng Zhang, et al. 2022. “Freezing Solute Atoms in Nanograined Aluminum Alloys via High-Density Vacancies.” Nature Communications 13 (1). https://doi.org/10.1038/s41467-022-31222-6.

- Wu, Wenqian, Mingyu Gong, Bingqiang Wei, Amit Misra, and Jian Wang. 2022. “Atomistic Modeling of Interface Strengthening in Al-Si Eutectic Alloys.” Acta Materialia 225. https://doi.org/10.1016/j.actamat.2021.117586.

- Xing, Yurui, Lianshun Luo, Yansong Li, Dongxu Wang, Dayong Hu, Tao Li, and Hongti Zhang. 2022. “Exploration of Hierarchical Metal–Organic Framework as Ultralight, High-Strength Mechanical Metamaterials.” Journal of the American Chemical Society 144 (10): 4393–4402. https://doi.org/10.1021/jacs.1c11136.

- Yao, Ning, Tiwen Lu, Kai Feng, Binhan Sun, Run Zi Wang, Ji Wang, Yu Xie, et al. 2022. “Ultrastrong and Ductile Additively Manufactured Precipitation-Hardening Medium-Entropy Alloy at Ambient and Cryogenic Temperatures.” Acta Materialia 236. https://doi.org/10.1016/j.actamat.2022.118142.

- Yifan Zhang. 2022. “Mechanical Property And Deformation Mechanisms Of Nanotwinned Aluminum Alloys And Multilayers.”

- Yoh, Hao Zhe, Yaping Chen, Stella Aslanoglou, Sherman Wong, Zlatan Trifunovic, Simon Crawford, Esther Lestrell, et al. 2022. “Polymeric Nanoneedle Arrays Mediate Stiffness‐Independent Intracellular Delivery.” Advanced Functional Materials 32 (3). https://doi.org/10.1002/adfm.202104828.

- Zgłobicka, Izabela, and Krzysztof J. Kurzydłowski. 2022. “Multi-Length Scale Characterization of Frustule Showing Highly Hierarchal Structure in the Context of Understanding Their Mechanical Properties.” Materials Today Communications 33. https://doi.org/10.1016/j.mtcomm.2022.104741.

- Zhang, Qian, Ruirui Huang, Jiaxi Jiang, Tangqing Cao, Yongpan Zeng, Jianguo Li, Yunfei Xue, and Xiaoyan Li. 2022. “Size Effects and Plastic Deformation Mechanisms in Single-Crystalline CoCrFeNi Micro/Nanopillars.” Journal of the Mechanics and Physics of Solids 162. https://doi.org/10.1016/j.jmps.2022.104853.

- Zhang, Shuangshuang, Zihe Li, Kun Luo, Julong He, Yufei Gao, Alexander v. Soldatov, Vicente Benavides, et al. 2022. “Discovery of Carbon-Based Strongest and Hardest Amorphous Material.” National Science Review 9 (1). https://doi.org/10.1093/nsr/nwab140.

- Zhao, Hu, Halil Yilmaz, Craig J. Williams, Alexander S. Eggeman, and Brian Derby. 2022. “Influence of Twin Boundaries and Sample Dimensions on the Mechanical Behavior of Ag Nanowires.” Materials Science and Engineering: A 829. https://doi.org/10.1016/j.msea.2021.142150.

- Abdullatif Altabtabaei. 2021. “High-Temperature Nano-Indentation of Ni-Based Superalloy with Unimodal and Bimodal Precipitate Distributions.”

- Acharya, R., L. Borkowski, B. Fisher, J. Sharon, A. Staroselsky, and A. Ventura. 2023. “Computational Tools for Additive Manufacture of Tailored Microstructure and Properties.” Metallography, Microstructure, and Analysis 12 (6). https://doi.org/10.1007/s13632-023-01023-4.

- Adam Gabriel. 2021. “Radiation Response And Mechanical Property Changes Of Chromium As Accident-Tolerant Fuel Cladding Coating.”

- Ajantiwalay, Tanvi, Lauren Nagel, Stuart Maloy, Khalid Hattar, John J. Mecholsky, and Assel Aitkaliyeva. 2021. “Investigation of Hardening Mechanisms and Size Effects in Proton-Irradiated HT-9 Steels.” Journal of Nuclear Materials 548. https://doi.org/10.1016/j.jnucmat.2021.152866.

- Aleman, A., H. Zaid, B. M. Cruz, K. Tanaka, J. M. Yang, H. Kindlund, and S. Kodambaka. 2021. “Room-Temperature Plasticity and Size-Dependent Mechanical Responses in Small-Scale B1-NbC(001) Single-Crystals.” Acta Materialia 221. https://doi.org/10.1016/j.actamat.2021.117384.

- Azadehranjbar, Soodabeh, Bingqiang Wei, Dongyue Xie, Kaisheng Ming, Jian Wang, and Jeffrey E. Shield. 2021. “Strength and Plasticity of Lamellar vs. Fibrous Eutectic Mg-Al Nanocomposites: An in-Situ Microcompression Study.” Acta Materialia 206. https://doi.org/10.1016/j.actamat.2021.116624.

- Bae, Jae‐Young, Eun‐Ji Gwak, Gyeong‐Seok Hwang, Hae Won Hwang, Dong‐Ju Lee, Jong‐Sung Lee, Young‐Chang Joo, et al. 2021. “Biodegradable Metallic Glass for Stretchable Transient Electronics.” Advanced Science 8 (10). https://doi.org/10.1002/advs.202004029.

- Bisht, Anuj, Raj Kiran Koju, Yuanshen Qi, James Hickman, Yuri Mishin, and Eugen Rabkin. 2021. “The Impact of Alloying on Defect-Free Nanoparticles Exhibiting Softer but Tougher Behavior.” Nature Communications 12 (1). https://doi.org/10.1038/s41467-021-22707-x.

- Bisht, Anuj, Raj koju, Yuanshen Qi, James Hickman, Yuri Mishin, and Eugen Rabkin. 2021. “Softer but Tougher: The Impact of Alloying on Defect-Free Nanoparticles.” https://doi.org/10.21203/rs.3.rs-140098/v1.

- Briggs, Samuel A., Mackenzie Steckbeck, Nathan M. Heckman, Timothy A. Furnish, Daniel C. Bufford, Daniel Buller, Brad L. Boyce, and Khalid Hattar. 2021. “A Combined Thermomechanical and Radiation Testing Platform for a 6 MV Tandem Accelerator.” Nuclear Instruments and Methods in Physics Research, Section B: Beam Interactions with Materials and Atoms 509. https://doi.org/10.1016/j.nimb.2021.08.011.

- Brinckmann, Steffen, and Ruth Schwaiger. 2021. “Towards Enhanced Nanoindentation by Image Recognition.” Journal of Materials Research 36 (11): 2266–76. https://doi.org/10.1557/s43578-021-00173-x.

- Buchinger, J., A. Wagner, Z. Chen, Z. L. Zhang, D. Holec, P. H. Mayrhofer, and M. Bartosik. 2021. “Fracture Toughness Trends of Modulus-Matched TiN/(Cr,Al)N Thin Film Superlattices.” Acta Materialia 202. https://doi.org/10.1016/j.actamat.2020.10.068.

- Budiman, Arief S., Rahul Sahay, Hashina Parveen Anwar Ali, Sasi K. Tippabhotla, Ihor Radchenko, and Nagarajan Raghavan. 2021. “Interface-Mediated Plasticity and Fracture in Nanoscale Cu/Nb Multilayers as Revealed by in Situ Clamped Microbeam Bending.” Materials Science and Engineering: A 803. https://doi.org/10.1016/j.msea.2020.140705.

- Burtscher, Michael, Markus Alfreider, Klemens Schmuck, Helmut Clemens, Svea Mayer, and Daniel Kiener. 2021. “In Situ Fracture Observations of Distinct Interface Types within a Fully Lamellar Intermetallic TiAl Alloy.” Journal of Materials Research 36 (12): 2465–78. https://doi.org/10.1557/s43578-020-00088-z.

- Chen, Wufan, Xiaoyuan Wang, Yabin Yan, Takashi Sumigawa, Takayuki Kitamura, Miaolin Feng, and Fu Zhen Xuan. 2021. “Bending Stress Relaxation of Microscale Single-Crystal Copper at Room Temperature: An in Situ SEM Study.” European Journal of Mechanics, A/Solids 90. https://doi.org/10.1016/j.euromechsol.2021.104377.

- Chen, Yujie, Xianghai An, Sam Zhang, Feng Fang, Wenyi Huo, Paul Munroe, and Zonghan Xie. 2021. “Mechanical Size Effect of Eutectic High Entropy Alloy: Effect of Lamellar Orientation.” Journal of Materials Science and Technology 82. https://doi.org/10.1016/j.jmst.2020.11.067.

- Chen, Yujie, Xianghai An, Zhifeng Zhou, Jisheng Ma, Paul Munroe, Sam Zhang, and Zonghan Xie. 2021. “Remarkable Toughness of a Nanostructured Medium-Entropy Nitride Compound.” Nanoscale 13 (35). https://doi.org/10.1039/d1nr03289e.

- Chen, Yujie, Xianghai An, Zhifeng Zhou, Paul Munroe, Sam Zhang, Xiaozhou Liao, and Zonghan Xie. 2021. “Size-Dependent Deformation Behavior of Dual-Phase, Nanostructured CrCoNi Medium-Entropy Alloy.” Science China Materials 64 (1). https://doi.org/10.1007/s40843-020-1377-2.

- Chen, Yujie, Dengke Chen, Xianghai An, Yin Zhang, Zhifeng Zhou, Song Lu, Paul Munroe, et al. 2021. “Unraveling Dual Phase Transformations in a CrCoNi Medium-Entropy Alloy.” Acta Materialia 215. https://doi.org/10.1016/j.actamat.2021.117112.

- Chou, Kathleen, Nan Li, and Emmanuelle A. Marquis. 2021. “Enhanced Work Hardening from Oxygen-Stabilized ω Precipitates in an Aged Metastable β Ti-Nb Alloy.” Acta Materialia 220. https://doi.org/10.1016/j.actamat.2021.117302.

- Christos Michas. 2021. “High-Precision Fabrication Enables On-Chip Modeling with Organ-Level Structural and Mechanical Complexity.”

- Cui, Yuchi, Benjamin Derby, Nan Li, and Amit Misra. 2021. “Fracture Resistance of Hierarchical Cu–Mo Nanocomposite Thin Films.” Materials Science and Engineering: A 799. https://doi.org/10.1016/j.msea.2020.139891.

- Dang, Chaoqun, Weitong Lin, Fanling Meng, Hongti Zhang, Sufeng Fan, Xiaocui Li, Ke Cao, et al. 2021. “Enhanced Tensile Ductility of Tungsten Microwires via High-Density Dislocations and Reduced Grain Boundaries.” Journal of Materials Science and Technology 95. https://doi.org/10.1016/j.jmst.2021.04.021.

- Dongyue Xie. 2021. “Micro-Structure and Mechanical Properties of FeCrAl Alloys Under Extreme Environment.”

- Drnovšek, Aljaž, Hi T. Vo, Marisa Rebelo de Figueiredo, Szilard Kolozsvári, Peter Hosemann, and Robert Franz. 2021. “High Temperature Fracture Toughness of Single-Layer CrAlN and CrAlSiN Hard Coatings.” Surface and Coatings Technology 409. https://doi.org/10.1016/j.surfcoat.2021.126909.