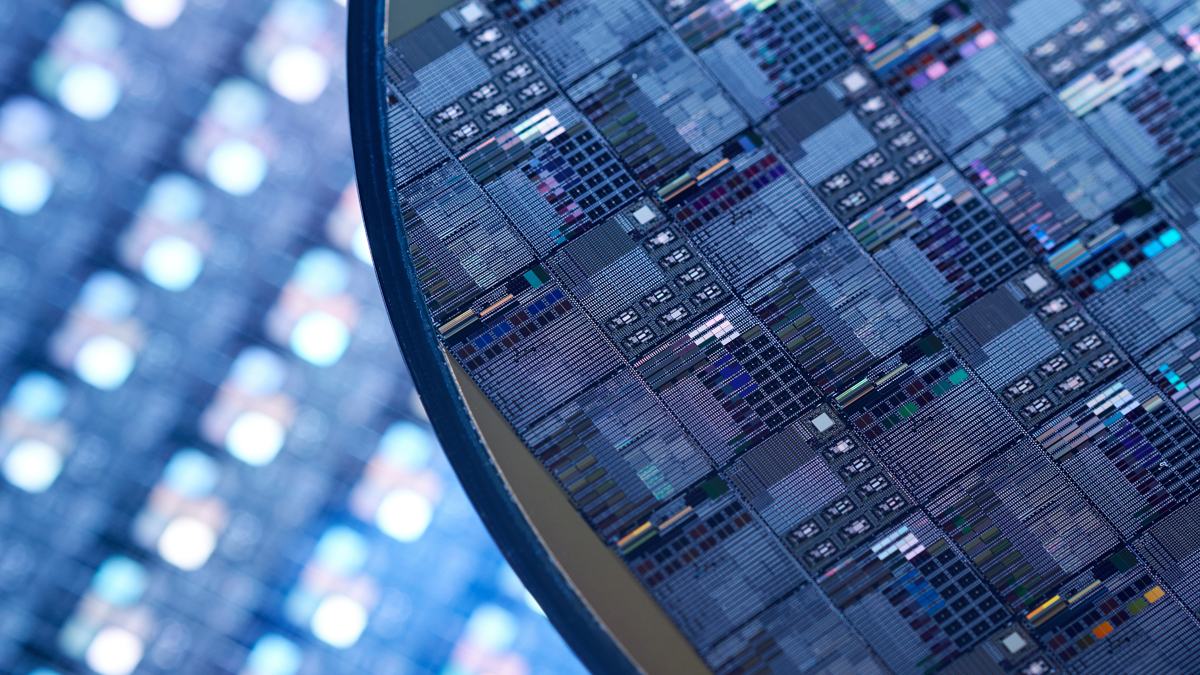

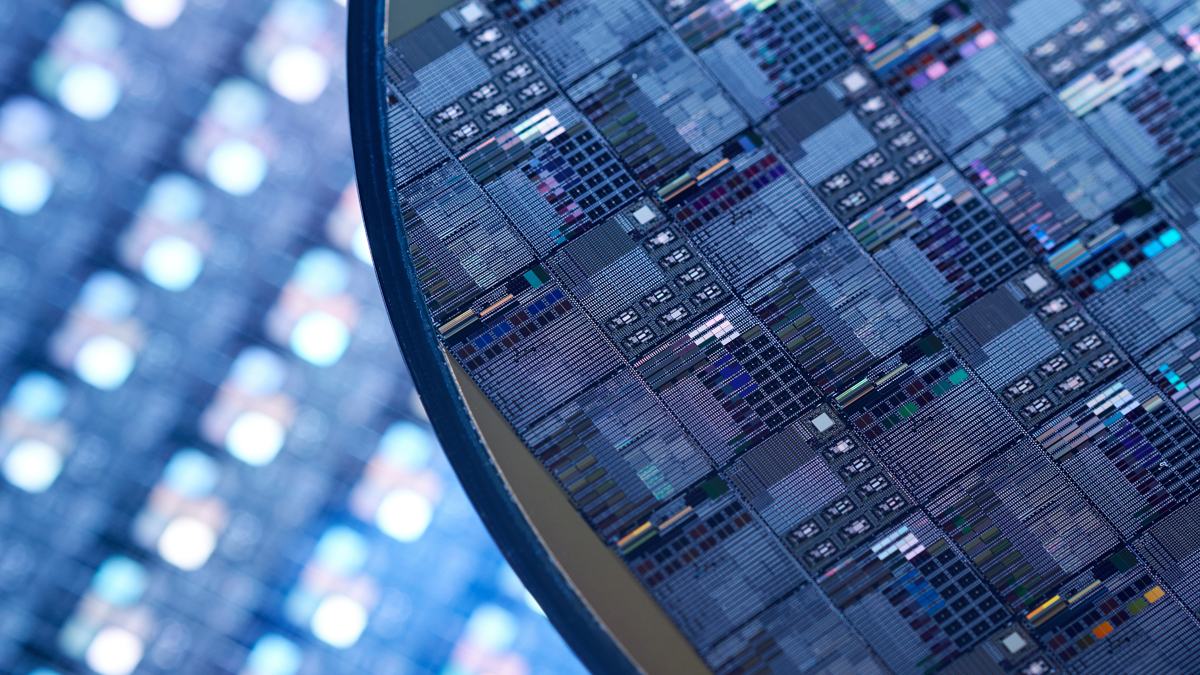

Semiconductor Solutions

Advanced Solutions for Semiconductor

Bruker's suite of technologies for semiconductor manufacturing address critical metrology and process needs across the broadest range of applications from R&D to process improvement. 75% of the world's top 25 semiconductor manufacturers rely on Bruker metrology tools for front-end and back-end applications, including development of their next-generation products. Bruker commitment to innovation and technology leadership drives the continued release of new advancements in metrology, and has garnered numerous awards and industry recognition.

Support

How Can We Help?

Bruker partners with our customers to solve real-world application issues. We develop next-generation technologies and help customers select the right system and accessories. This partnership continues through training and extended service, long after the tools are sold.

Our highly trained team of support engineers, application scientists and subject-matter experts are wholly dedicated to maximizing your productivity with system service and upgrades, as well as application support and training.