Soluciones de semiconductores

Advanced Solutions for Semiconductor

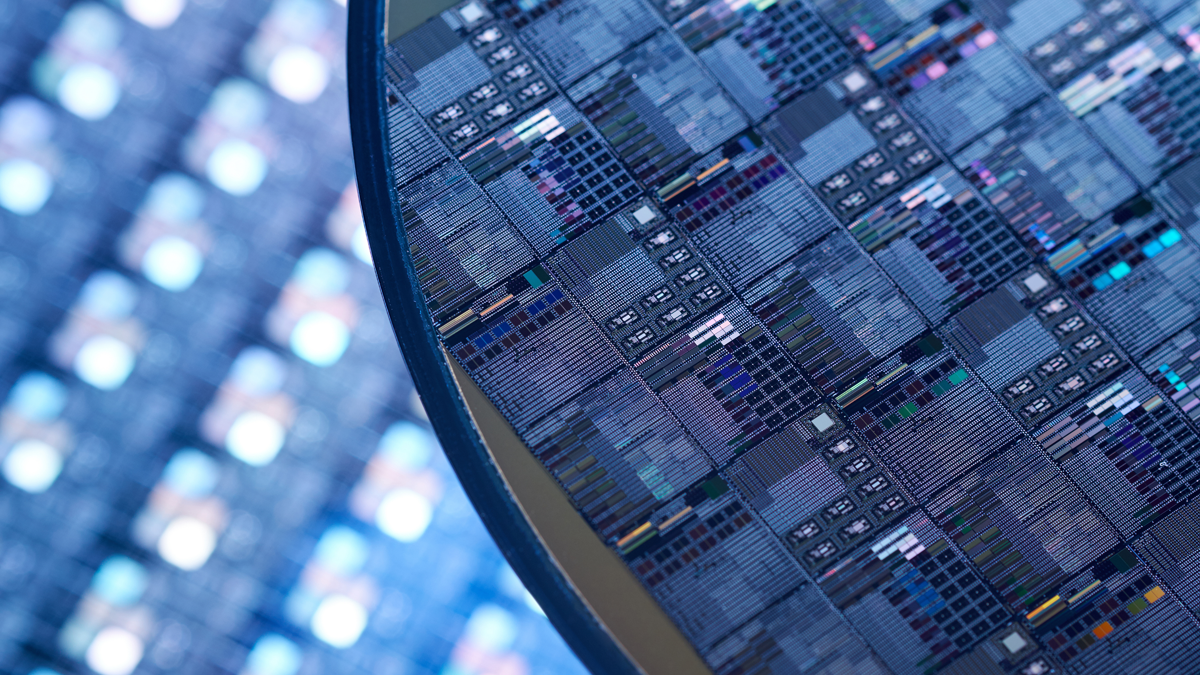

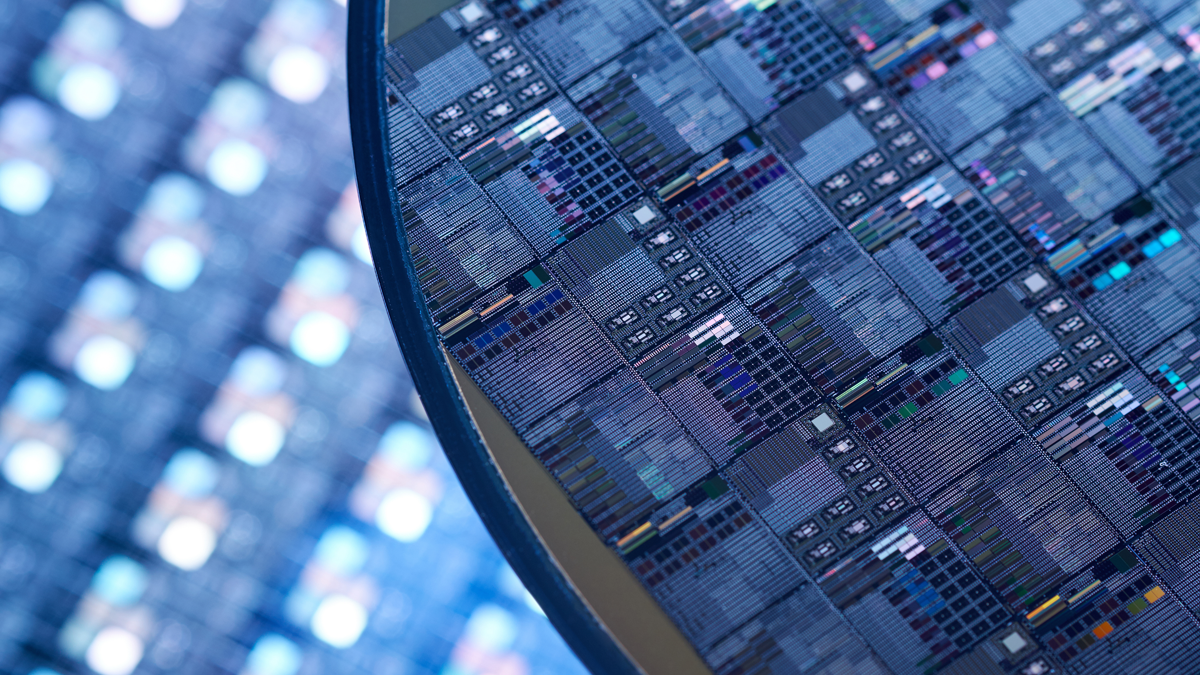

Bruker's suite of technologies for semiconductor manufacturing address critical metrology and process needs across the broadest range of applications from R&D to process improvement. 75% of the world's top 25 semiconductor manufacturers rely on Bruker metrology tools for front-end and back-end applications, including development of their next-generation products. Bruker commitment to innovation and technology leadership drives the continued release of new advancements in metrology, and has garnered numerous awards and industry recognition.

Soluciones de metrología para semiconductores

Bruker Semiconductor desarrolla, fabrica, comercializa y da asistencia a soluciones de metrología para películas delgadas que se basan en una tecnología de rayos X novedosa, rápida, sin contacto y no destructiva. Con la adquisición por parte de Bruker de Jordan Valley Semiconductors, un nombre sinónimo de servicio y asistencia al cliente mundial inigualables, el 75% de los veinticinco principales fabricantes de semiconductores del mundo confían en las herramientas de metrología de Bruker para aplicaciones front-end y back-end, incluyendo el desarrollo de sus películas finas de última generación. El compromiso de Bruker con la innovación y el liderazgo tecnológico impulsa el lanzamiento constante de nuevos avances en metrología y va cosechando numerosos premios y reconocimientos de la industria.

En aplicaciones que van desde la caracterización de materiales de películas delgadas hasta el análisis de sustratos de obleas y la detección de defectos, los sistemas de Bruker proporcionan análisis de simulación y ajuste. Los tipos de medición HRXRD, XRR, WA-XRD y XRDI son totalmente compatibles, lo que permite a los investigadores, ingenieros de producción y desarrolladores de procesos disponer de capacidades sin igual. Tanto si es usted un fabricante de semiconductores, una academia, un centro de I+D o una instalación de investigación de materiales industriales, Bruker tiene una solución específicamente diseñada para sus necesidades de metrología.

Support

How Can We Help?

Bruker partners with our customers to solve real-world application issues. We develop next-generation technologies and help customers select the right system and accessories. This partnership continues through training and extended service, long after the tools are sold.

Our highly trained team of support engineers, application scientists and subject-matter experts are wholly dedicated to maximizing your productivity with system service and upgrades, as well as application support and training.