QUANTAX EDS for SEM

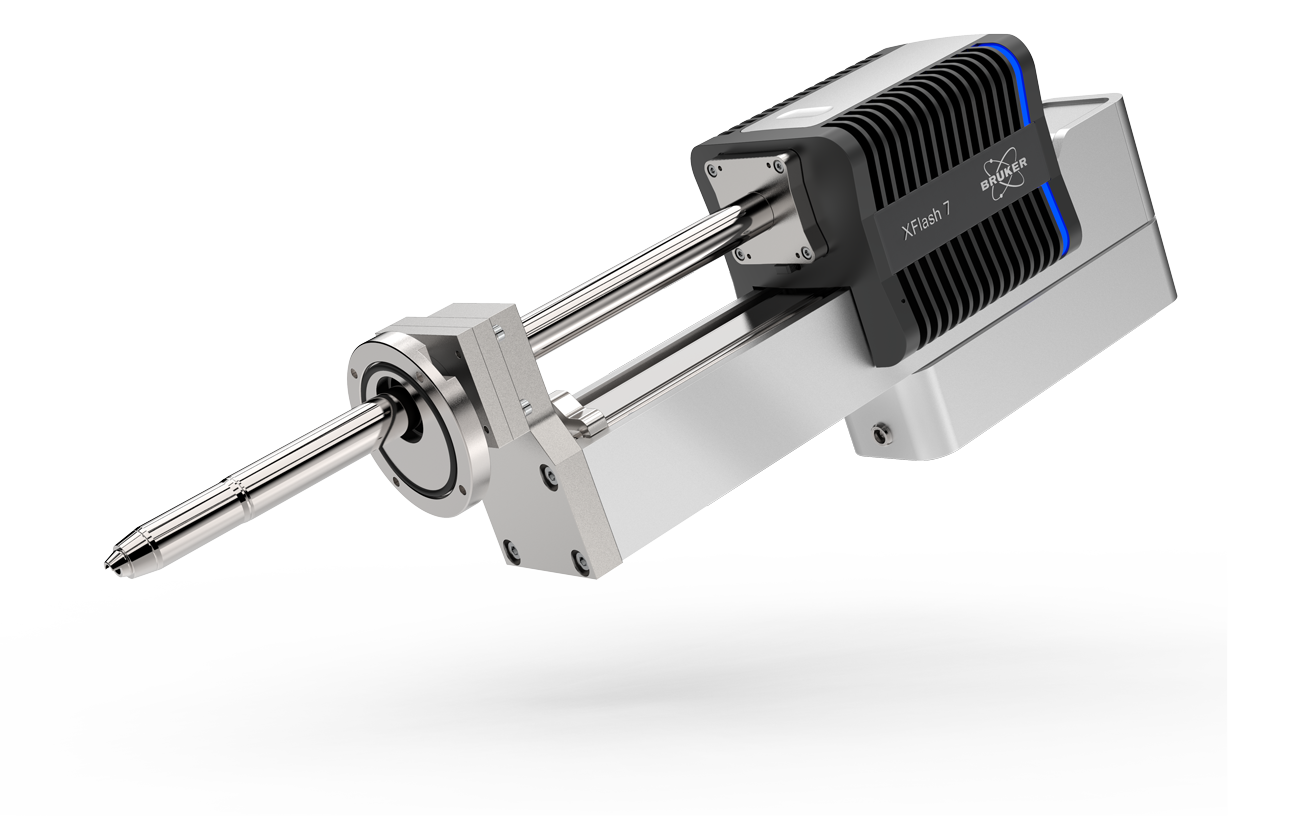

XFlash® 7 - The Latest EDS Detector Series

The Right Angle for Better Analysis

Fast. Precise. Reliable.

1,000,000

cps

Real analytical throughput up to 1,000,000 cps

Achieve unmatched analysis speed

> 2,200

Element lines

Quantify the most complex data using the most comprehensive atomic database incl. K, L, M and N lines

> 1.1

sr

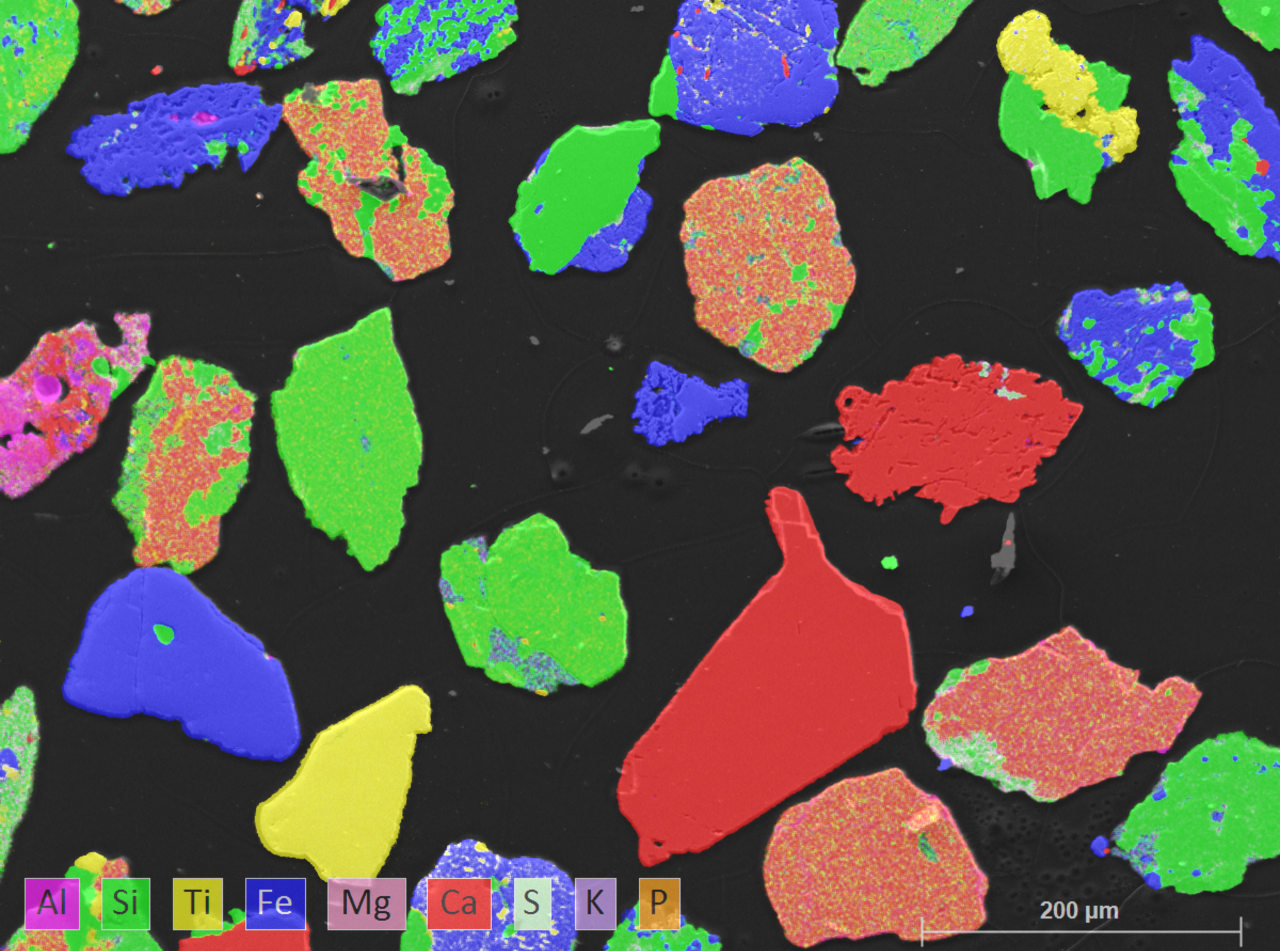

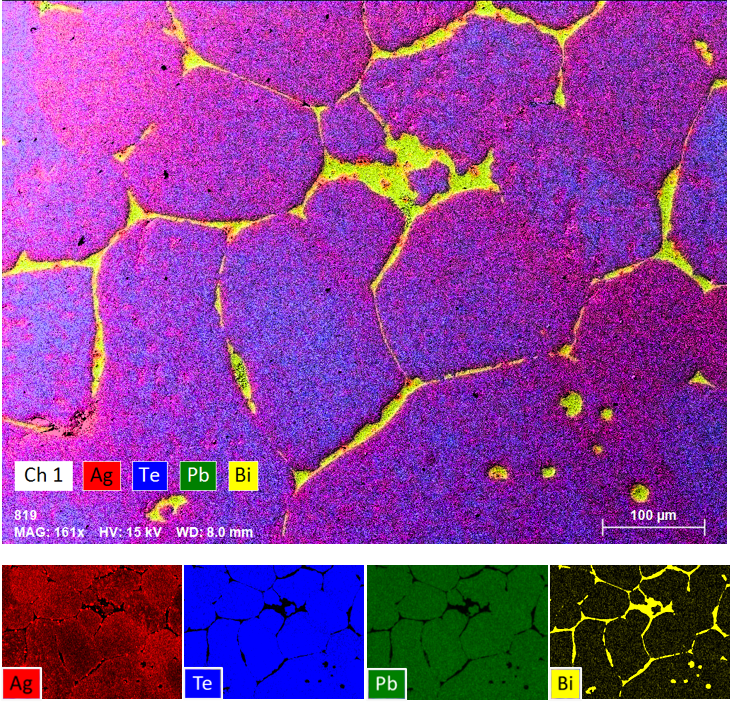

Largest solid angle for X-ray collection

Maximize your sample throughput with optimum geometry for most efficient collection of the generated X-rays

Energy-Dispersive Spectrometry for SEM, FIB-SEM and EPMA

- Bruker's latest generation of QUANTAX EDS features the XFlash® 7 detector series, which provides the largest solid angle for X-ray collection (also called collection angle) and the highest throughput.

- The XFlash® 7 continues to set standards in performance and functionality in energy-dispersive spectrometry for the Scanning Electron Microscope (SEM), Focused Ion Beam (FIB-SEM) and Electron Probe Micro Analyzer (EPMA).

- The XFlash® 7 detector family also offers optimized solutions for EDS analysis of electron transparent specimens in TEM and SEM, as well as the unique XFlash® FlatQUAD, a detector made to answer your questions on challenging samples.

- Slim-line technology, large collection angle design and latest generation pulse processing.

- Increase system uptime with on-site SDD module exchange.

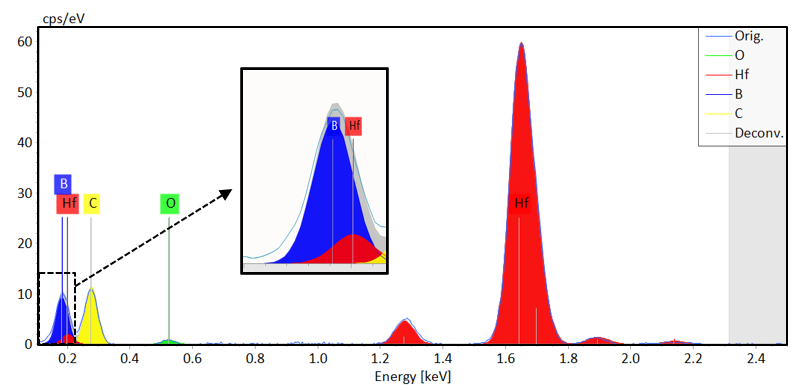

- Highest spectral performance obtained with best energy resolution.

- Increased accuracy of results by sophisticated quantification algorithms and a unique combination of standardless and standard-based methods.

Make Your Elemental Analysis more Efficient!

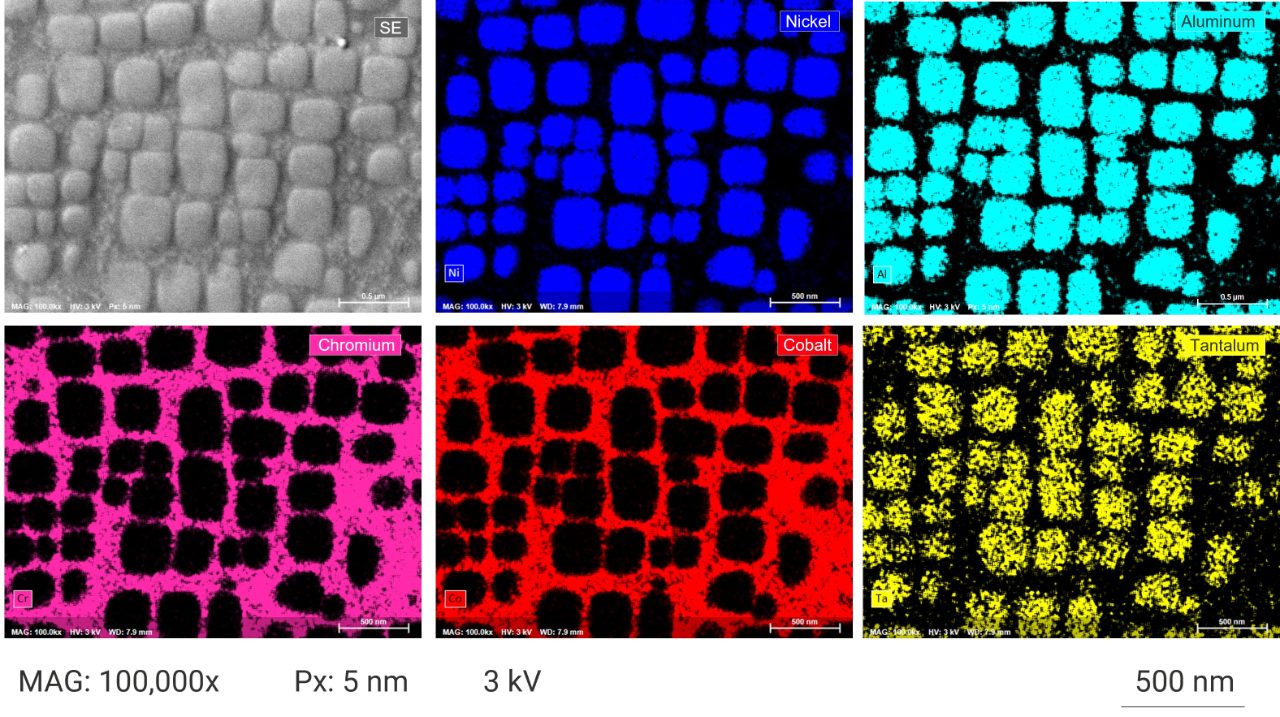

- Gain very precise results faster with individually optimized EDS systems. It ensures unmatched speed and precision.

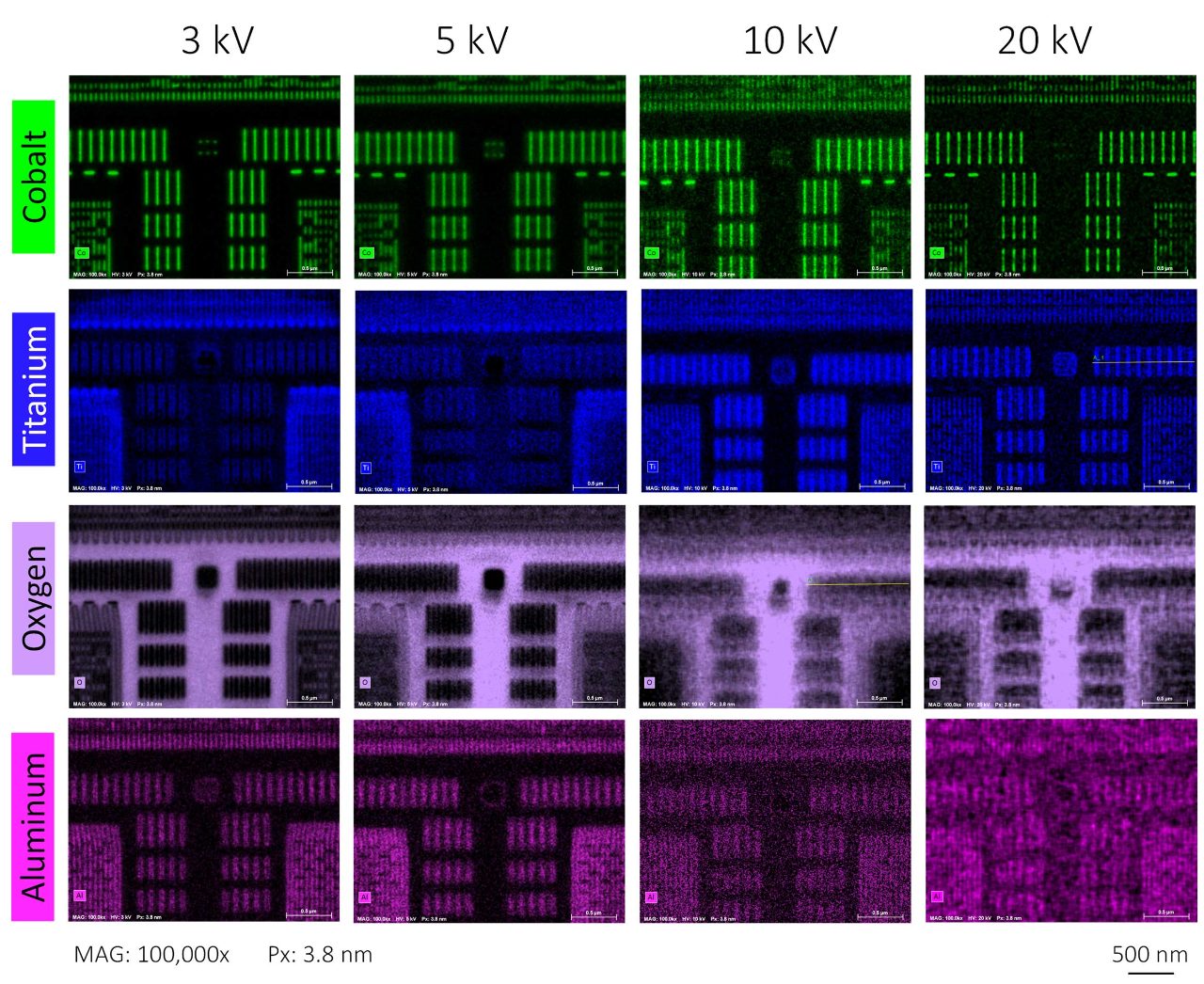

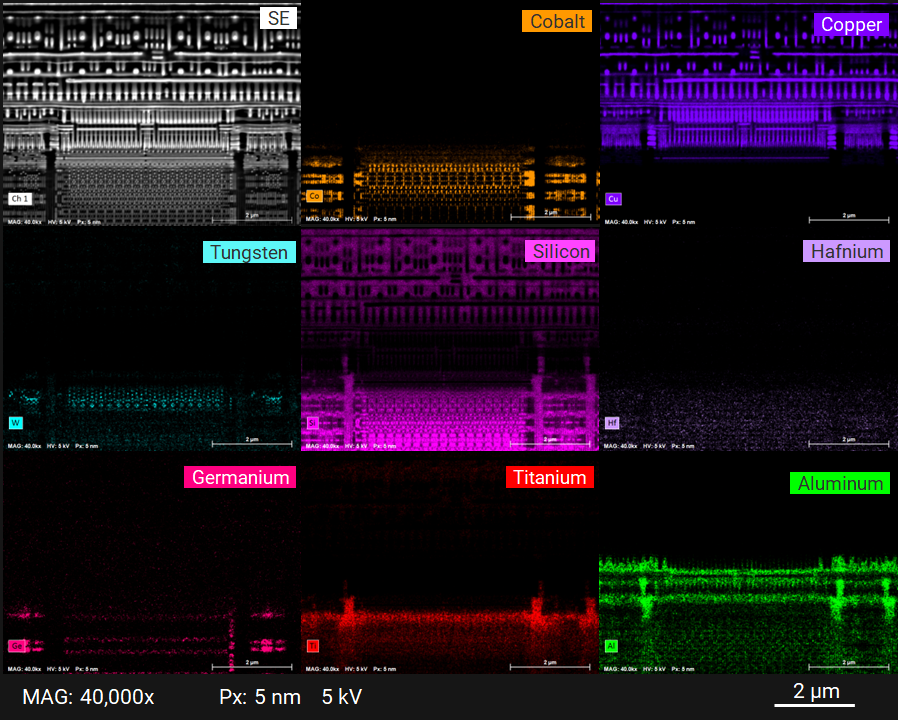

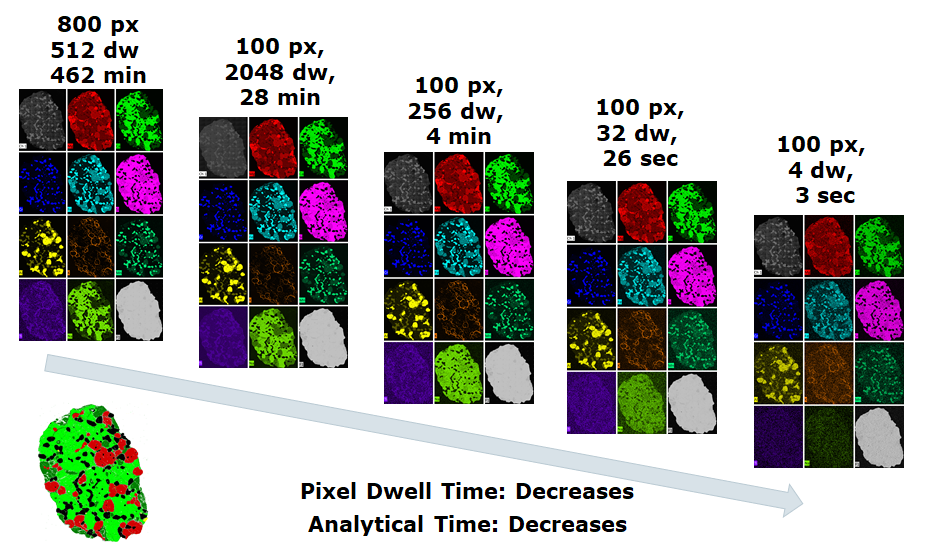

- Shorten measurement time with maximized throughput, enabling mapping and quantification at all settings with no limitation of data size.

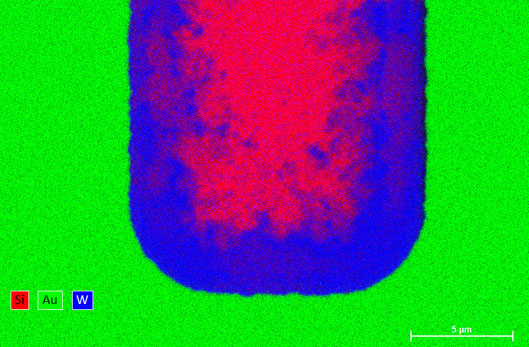

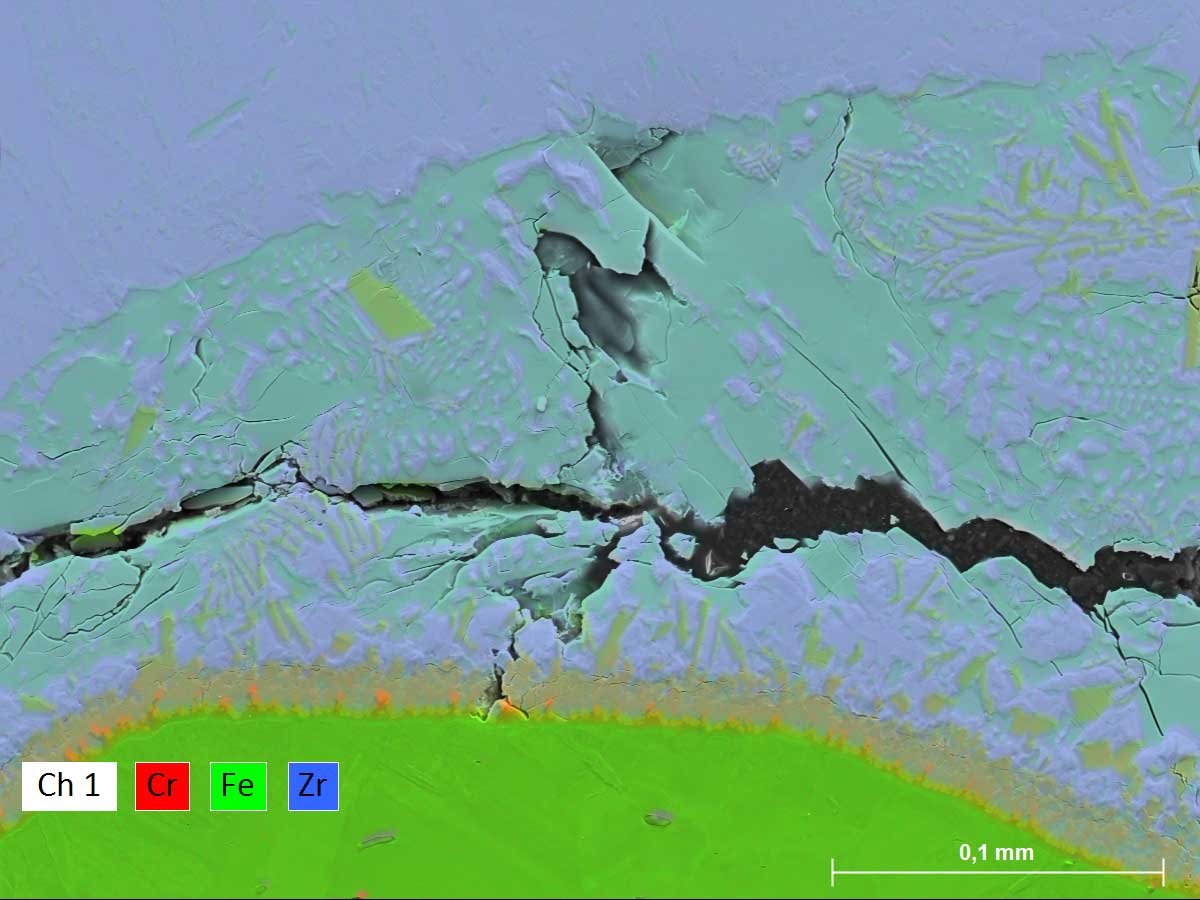

- Analyze challenging samples now, thanks to the most efficient geometric collection of generated X-rays.

- Benefit from accurate and reliable quantification results with optimized geometry minimizing background and avoiding absorption.

- Detect small quantities with better detection limit, lower background and less absorption.

- One for all - seamless integration of EDS, WDS, EBSD, and Micro-XRF in the comprehensive ESPRIT analysis platform for any SEM, FIB-SEM and EPMA.

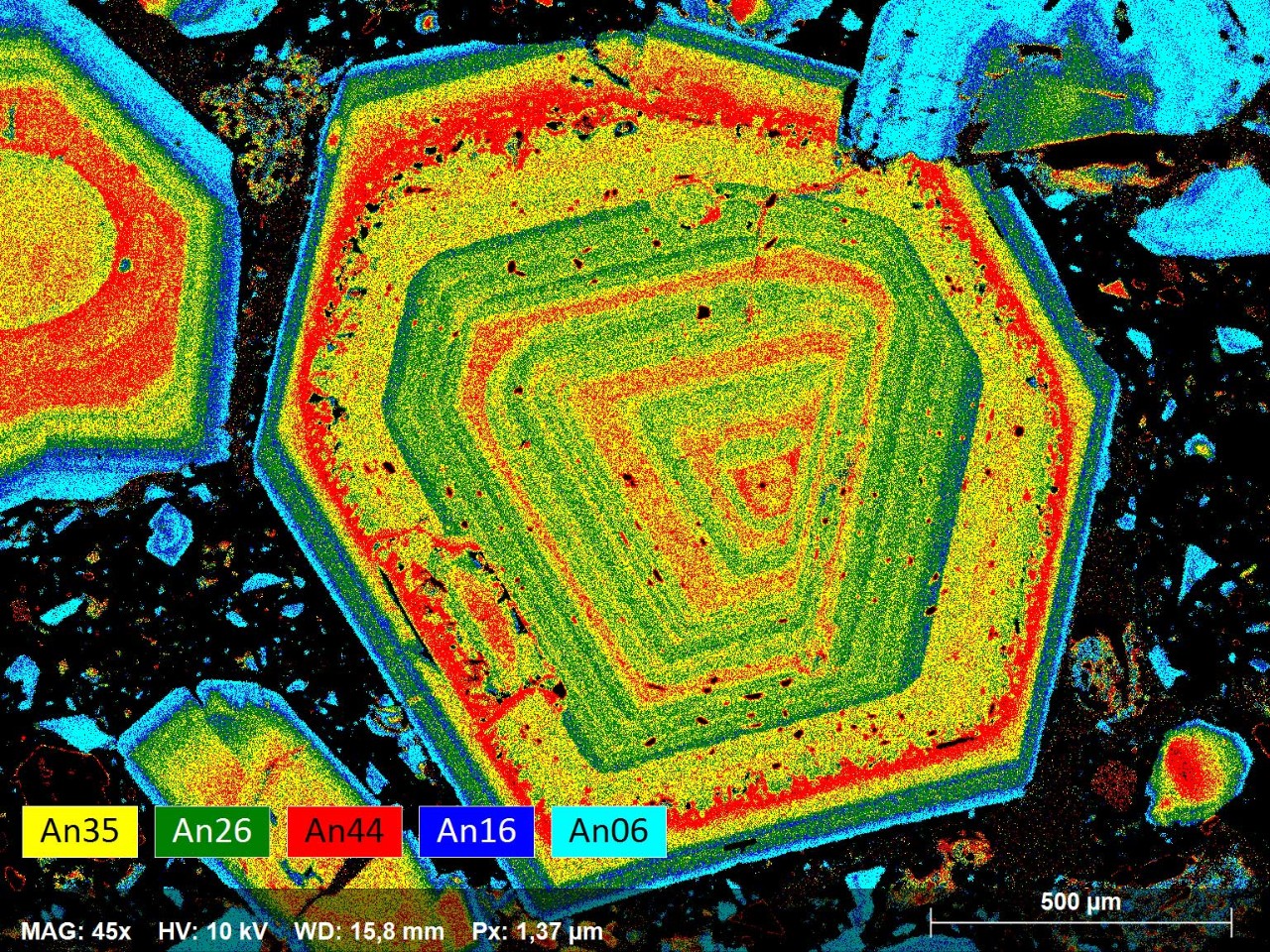

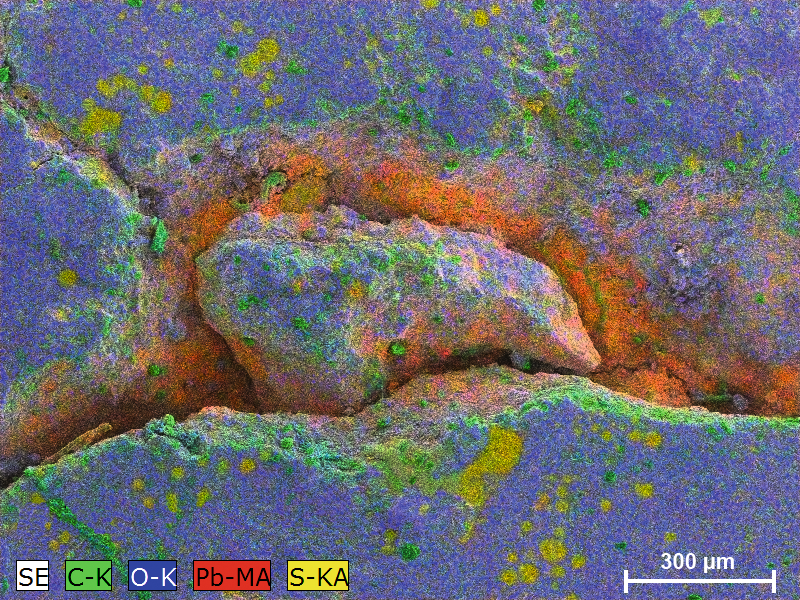

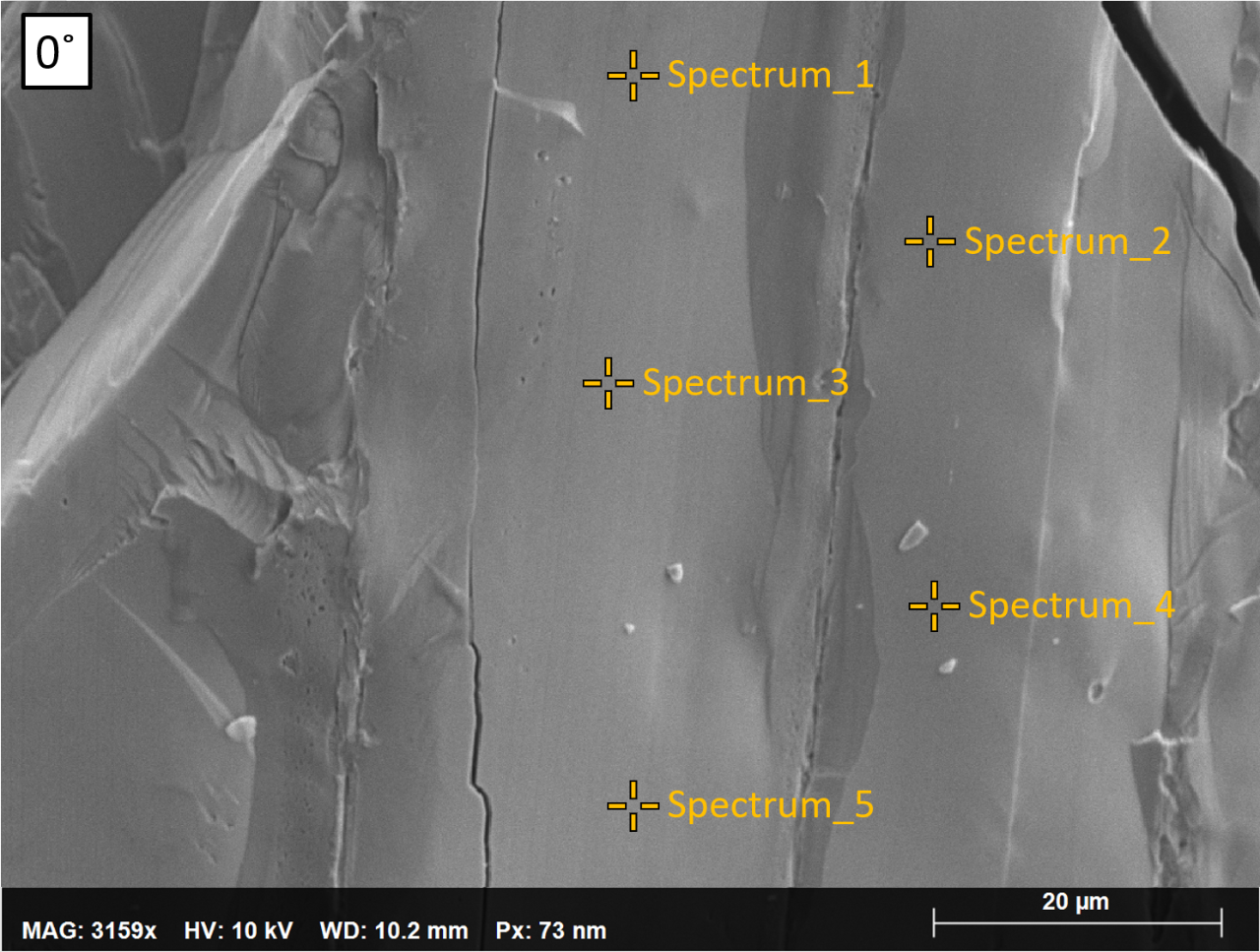

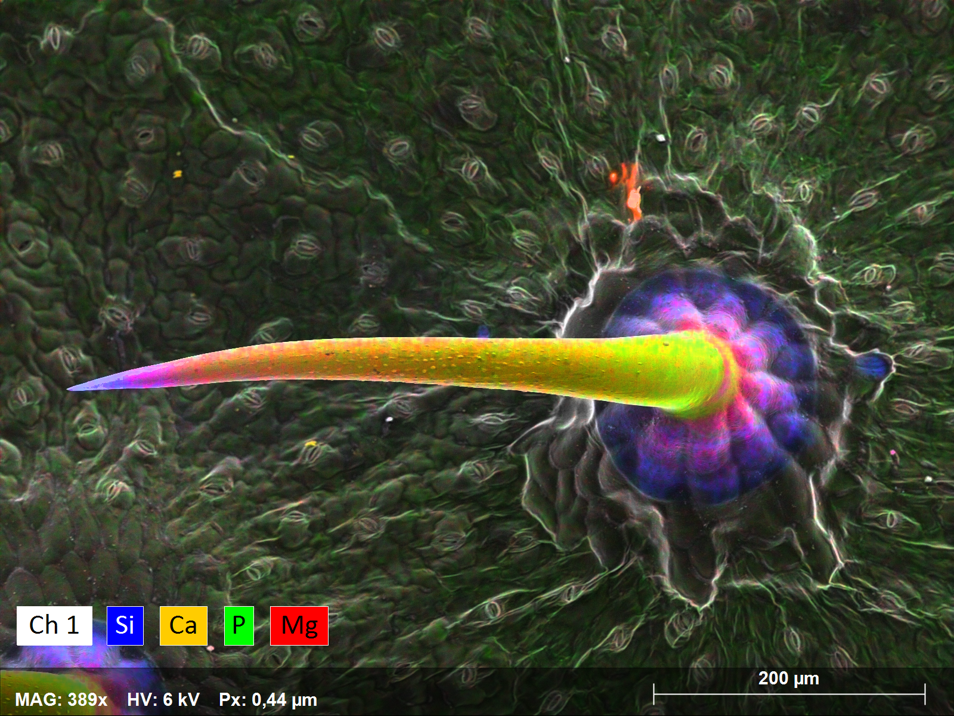

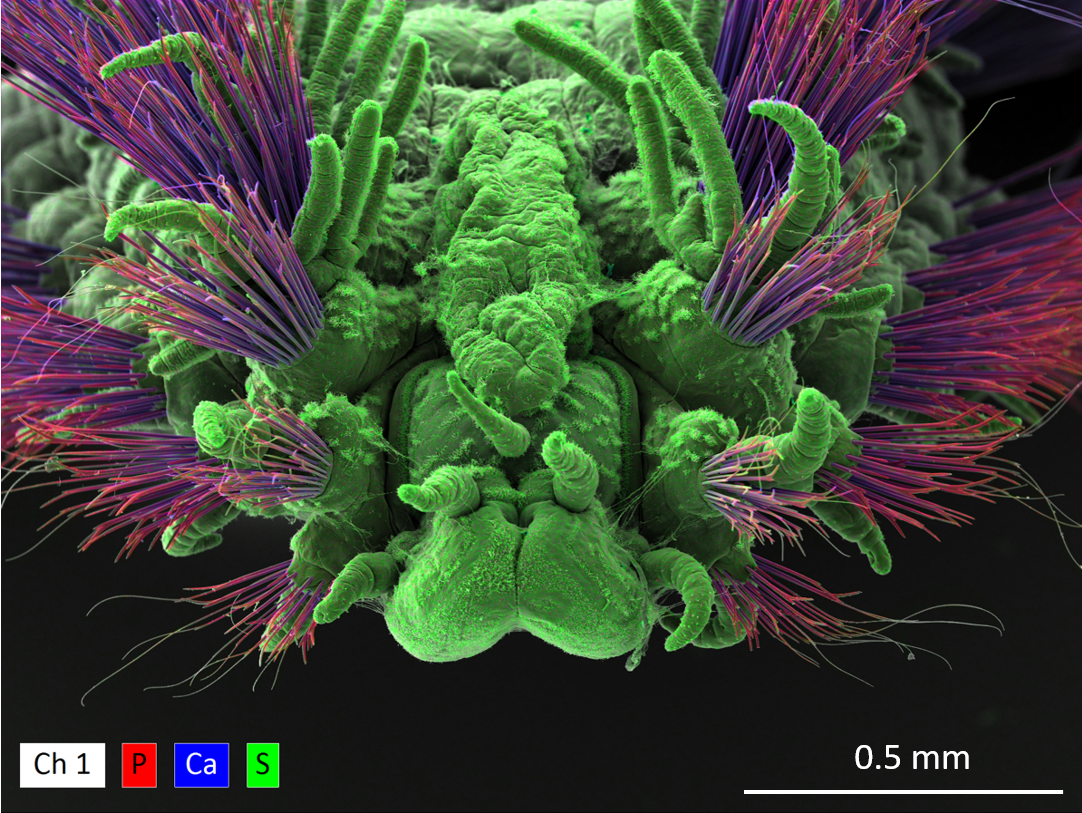

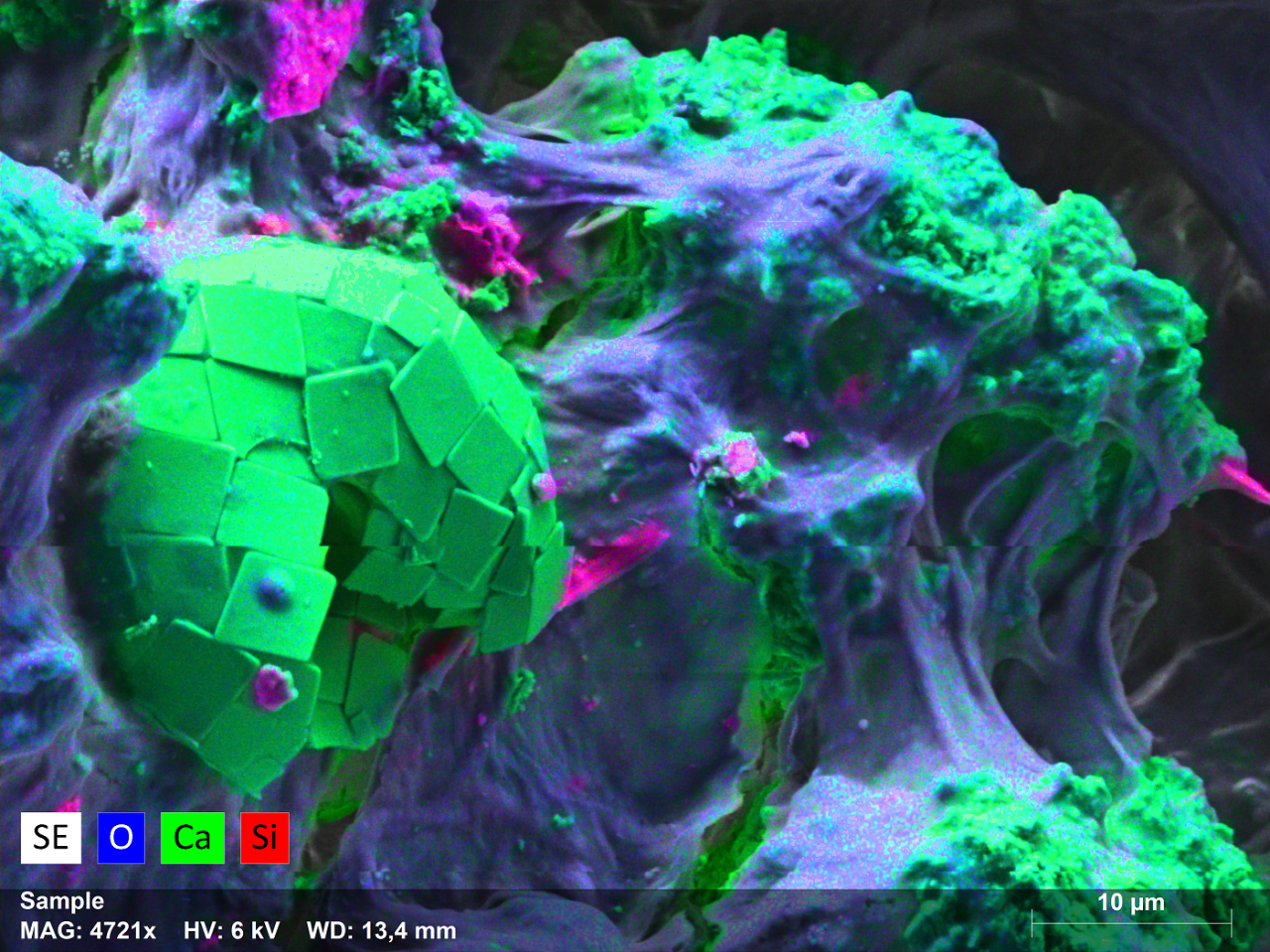

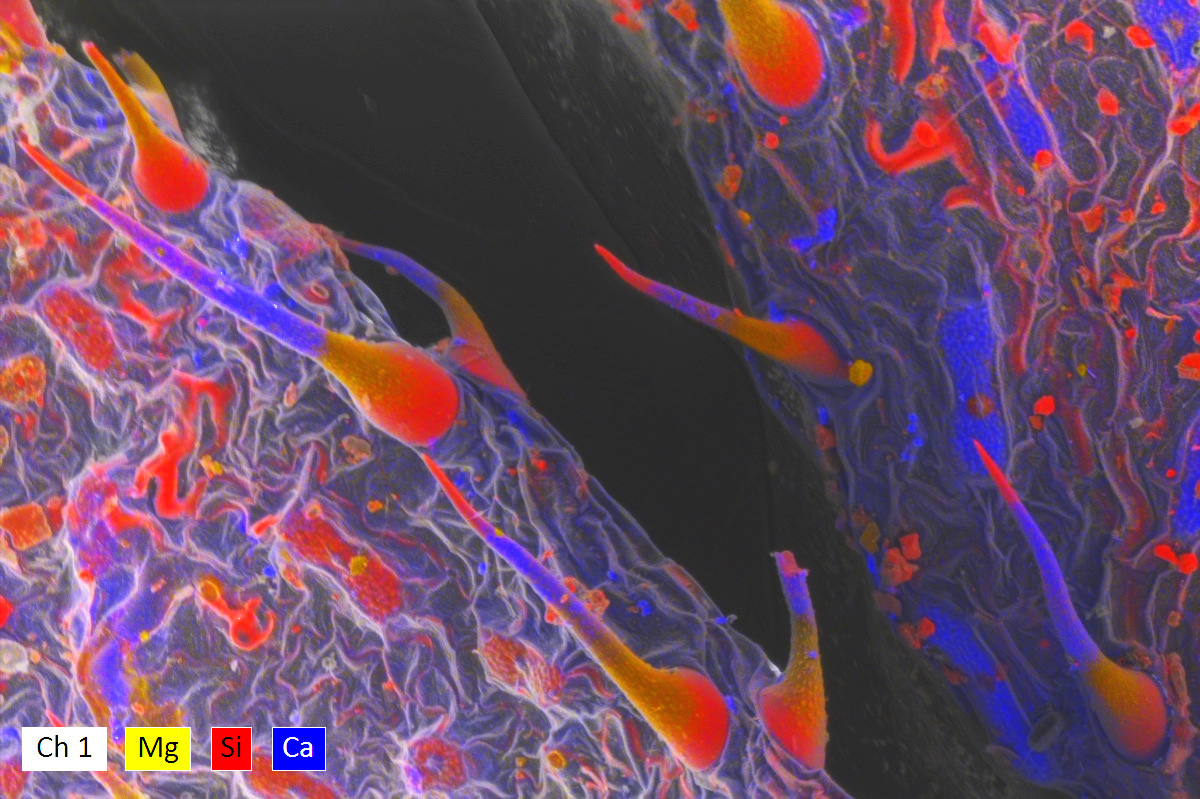

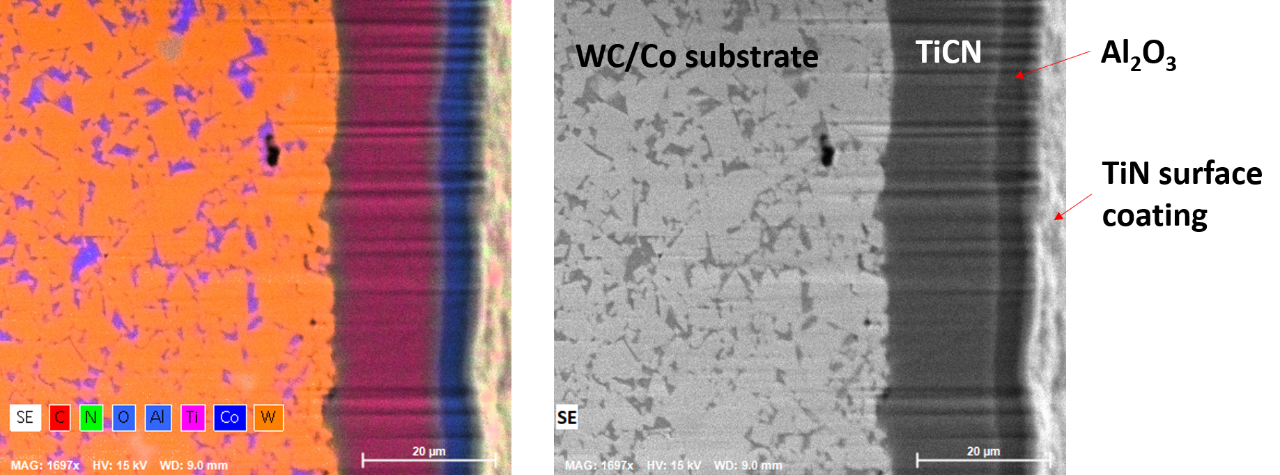

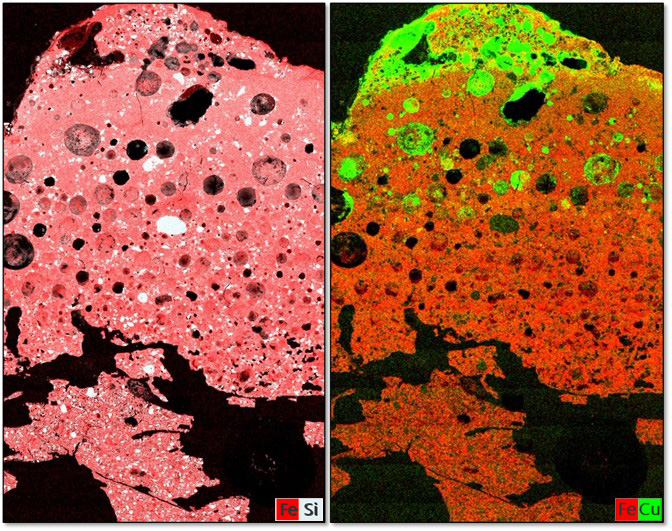

Applications of SEM EDS

Resources & Publications

Learn more about EDS

Interested in learning more about EDS? Visit our explainer page:

Learn about Full Range EDS - Combining EDS with micro-XRF on SEM

The combination of EDS with micro-XRF on SEM extends the energy range and elemental sensitivity. To find out more about this powerful combination visit our explainer page:

Application Notes

- EDS 01 - Comparison of standardless and standard-based quantification

- EDS 02 - Fast identification of mineral phases

- EDS 03 - Spectroscopic phase analysis of a ternary alloy

- EDS 04 - Identification of trace elements & corresponding phases with hyperspectral imaging

- EDS 05 - Specific small particle search by mineral grain feature analysis and chemical evaluation

- EDS 06 - Determination of the alite to belite ratio in Portland cement

- EDS 07 - High-resolution mapping of an oceanic drill core

- EDS 08 - Determining gunshot residue using 15 kV acceleration voltage with optimized spectra deconvolution

- EDS 09 - Light element quantification with TQuant: Analyzing boron nitride at different acceleration voltages

- EDS 10 - Advanced light element and low energy analysis of a ceramic material

- EDS 11 - Analysis of the elemental composition and thickness of a Fe-NI film on Si

- EDS 12 - High vacuum and low beam current analysis

- EDS 13 - Fast ore characterization

- EDS 14 - Low energy X-ray EDS analysis of ore mineralization

- EDS 16 - High-speed differentiation of mineral phases of similar BSE intensity

- Combined SEM Techniques 01 - Quantification of steel and alloys

Publications

- 2023 - Microscopy & Microanalysis: Improvement of Quantitative STEM/EDXS Analyses for Chemical Analysis of Cu(In,Ga)Se2 Solar Cells with Zn(O,S) Buffer Layers

- 2023 - Small: Boron and Sodium Doping of Polymeric Carbon Nitride Photoanodes for Photoelectrochemical Water Splitting

- 2022: Microscopy & Microanalysis: Measurement and Calculation of X-Ray Production Efficiencies for Copper, Zirconium, and Tungsten Get access Arrow

- 2022 - Surface and Interface Analysis: Elemental composition and thickness determination of thin films by electron probe microanalysis